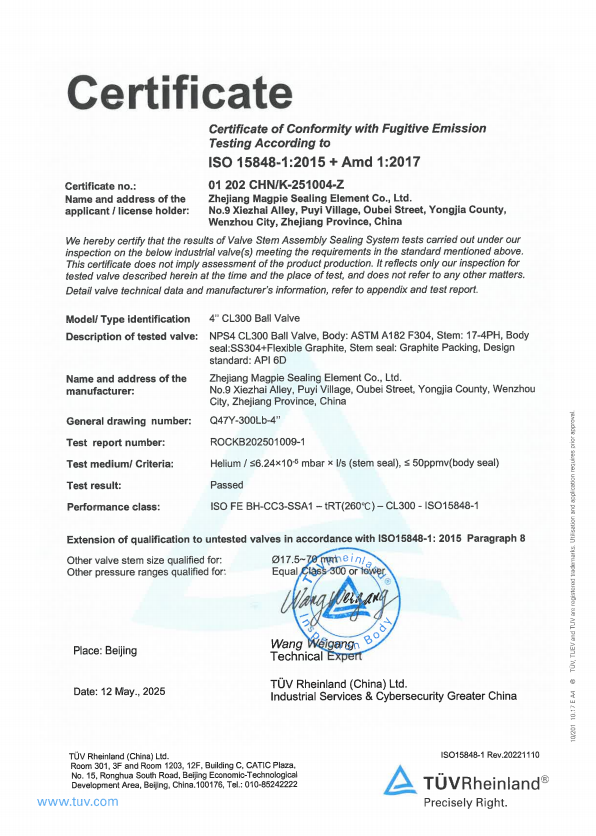

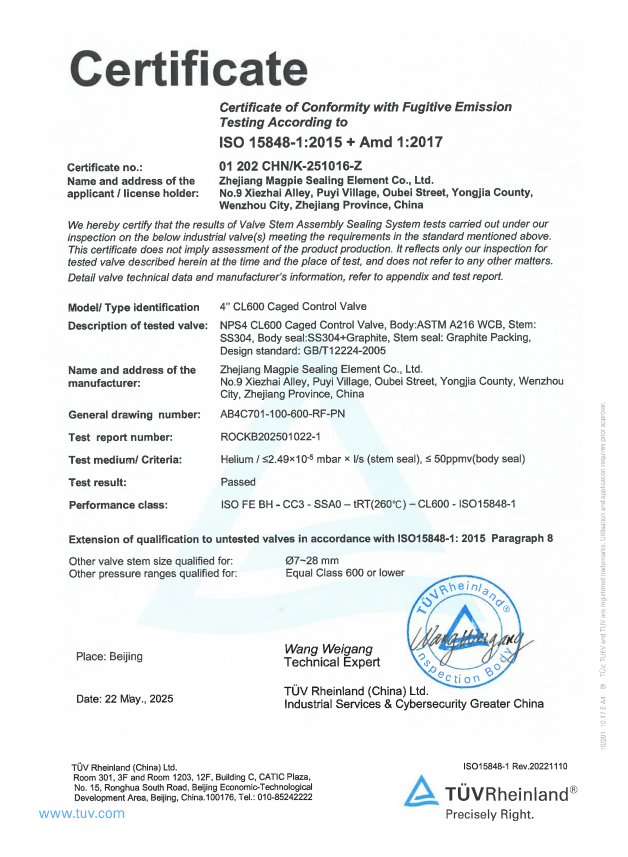

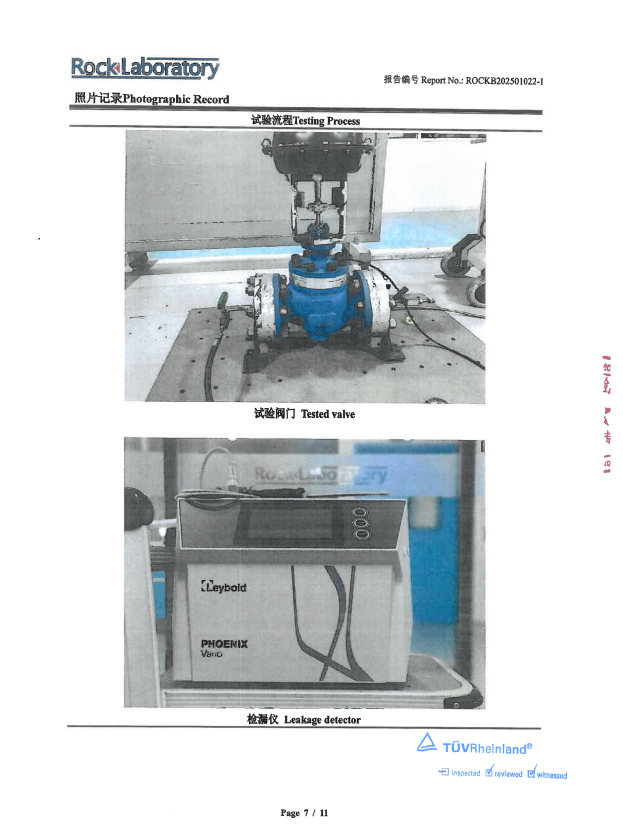

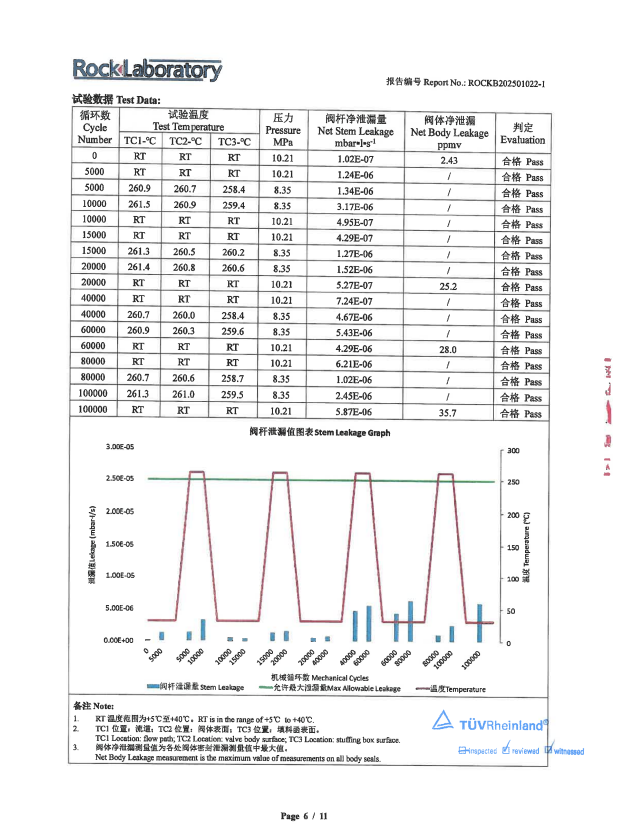

Magpie's ultra-long-life, low-emission packing has recently been witnessed by TÜV Rheinland and successfully obtained the ISO 15848-1 CC3, 260-degree, 100,000-cycle switch life certification for linear control valves and quarter-turn pneumatic ball valves. This achievement marks the international recognition of Xi Que's technical strength in the field of control valve packing.

With the advent of the digital age, the application scenarios of control valves are becoming increasingly complex, placing higher demands on the life and performance of packing seals. To meet this trend, Our team has been deeply engaged in researching the relationship between control valves and packing seals, striving to solve problems such as valve sticking and pneumatic head sealing failure during long-life operation of control valves.

During the R&D process, We found that conventional low-emission packing has excessive rigidity, which is only suitable for manual on-off valves. The valve stem of a manual on-off valve has a stop during the opening and closing process, unlike the continuous linear motion of a control valve without any stops, which requires higher friction resistance and wear resistance from the packing. In response to this characteristic, we has specifically developed a graphite packing with buffering and friction absorption capabilities. This packing not only has extremely low torque but also offers ultra-long wear resistance, perfectly solving the sealing challenges of control valves during long-life operation.

Made from flexible graphite material, the packing has a long-term temperature range of -196°C to +300°C, capable of withstanding various extreme operating conditions and providing reliable assurance for the stable operation of control valves. Looking ahead, we will continue to increase R&D investment, promote continuous innovation and upgrading of control valve packing technology, and contribute more to the development of the industrial sector in the digital age.