Taking the petroleum refining industry as an example, if a conventional valve has a daily average leakage rate of 500 standard cubic meters (calculated based on the volume of gas under standard conditions), for a large refinery with 100,000 valves, the annual media emission loss can be quantified in the following dimensions.

1. Direct Material Loss

Annual leakage volume = 100,000 valves × 500 Nm³/valve•day × 365 days = 1.825 billion standard cubic meters of gas. If the unit price of natural gas is 3 yuan/Nm³, the annual direct economic loss reaches 5.475 billion yuan (without considering the cost of media recovery).

2. Increased Operation and Maintenance Costs

High leakage rates lead to a 3-5 times increase in on-site inspection frequency, with an additional annual maintenance cost of 2,000-3,000 yuan per valve, resulting in an extra 200 million - 300 million yuan in annual O&M costs for the entire plant; emergency shutdowns and repairs caused by sudden leaks can result in average losses of millions of yuan per incident.

3. Compliance Risk Costs

Leakages exceeding environmental emission standards (such as the volatile organic compound leakage limits specified in China's "Pollutant Emission Standards for the Petroleum Chemical Industry") may face:

Single administrative penalty: 100,000 - 1 million yuan

Production suspension and rectification: Daily value loss can reach tens of millions of yuan

Brand reputation loss: Leading to downstream customer loss or restricted financing

4. Release of Hidden Value

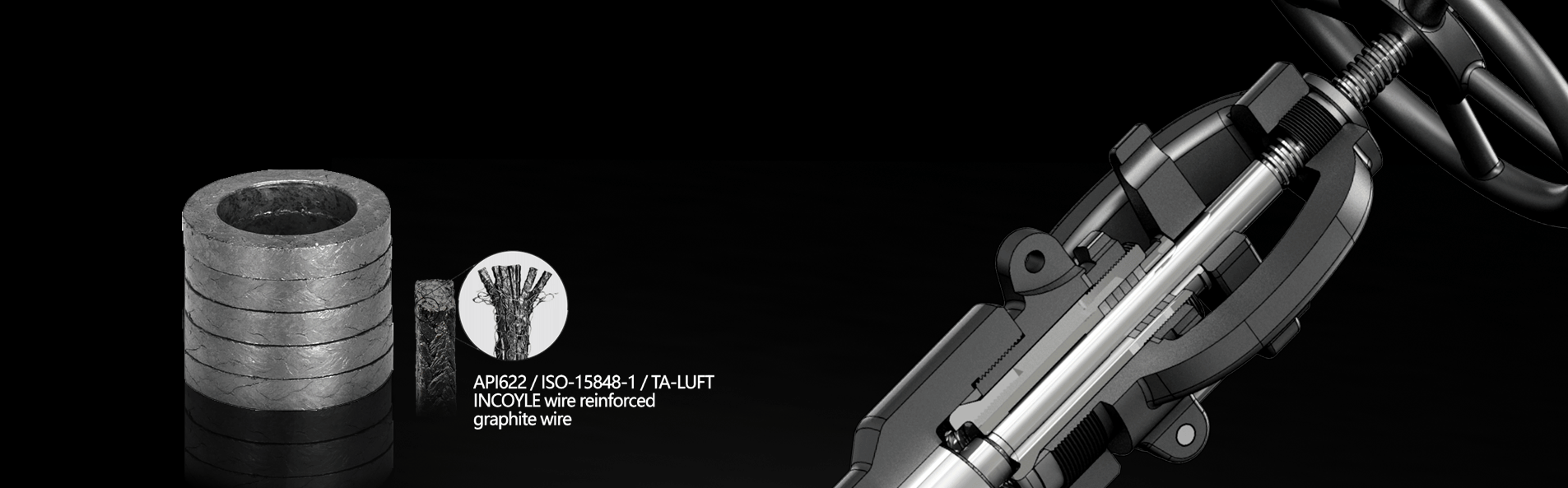

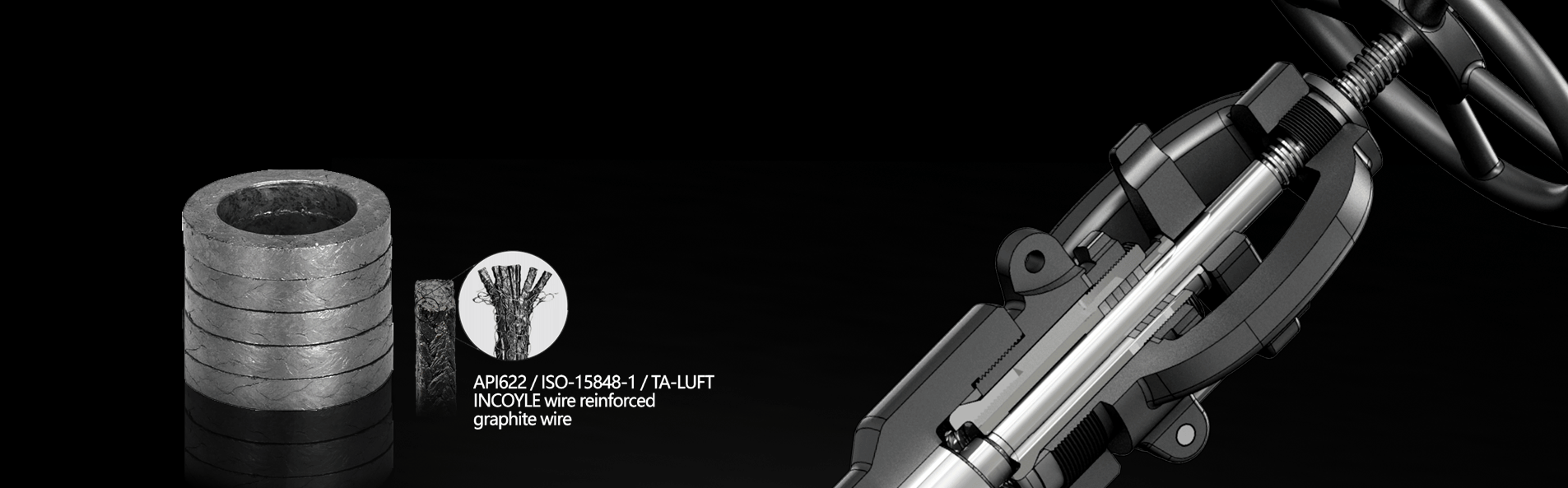

Using low emission valves (leakage rate ≤0.1 Nm³/valve•day) can achieve:

Annual emission reduction of over 1.8 billion cubic meters, meeting the carbon trading market quota requirements and creating additional revenue

More than 40% improvement in operation and maintenance efficiency, with a 5%-8% increase in overall equipment utilization rate

Avoidance of the risk of downgraded environmental credit rating, ensuring project approval and expansion qualifications

Conclusion: Low Emission Valves, through a three-dimensional value system of "material conservation control, operation and maintenance efficiency optimization, compliance risk isolation", can not only directly reduce losses of hundreds of millions of yuan but also build a sustainable development capability that meets ESG (environmental, social, and corporate governance) requirements. Especially under the "dual carbon" goals, they have become a core cost control tool for industries with high leakage risks.