Key Specifications / Features

The China M800 Combined Packing Supplier offers low-emission packing solutions specifically designed for control valves. These packing sets are engineered with die-formed graphite rings, ensuring superior sealing performance and compliance with both API 622 and API 607 standards. They are capable of withstanding pressures up to 4500 PSI (310 bar), making them highly reliable for demanding industrial applications. With a focus on minimizing fugitive emissions, these packing solutions provide enhanced safety and environmental protection.

- Model No.: MV-20250520-GP-03

- Hits: 51

- Categories: Graphite Packing

- Tags: API 622 Valve Packing, Control Valve Packing, Graphite Packing

Detail Information

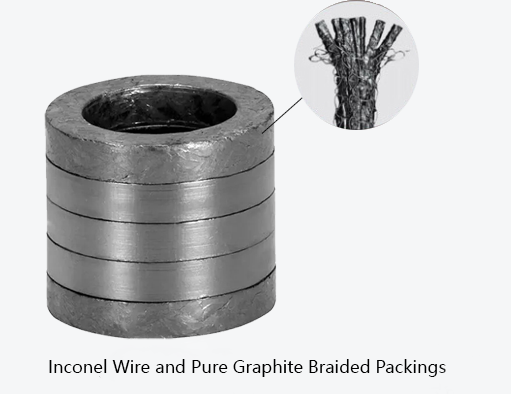

Product Name: M800 Combined Packing

The M800 combined packing is low-emission packing designed for control valves with high-frequency switching operations. It exceeds the API 622 test standards and features dynamic detection of leakage values, providing pressure fluctuation adaptability and more stable dynamic performance.

Structure: The middle part of the sealing ring is made of high-purity die-formed graphite ring structure. The end ring uses the M602 die-formed packing.

Temperature: -200°C to +450°C in Air, +450°C in Steam

PH Range: 0-14 (excluding strong oxidizing agents)

Pressure: Up to 4,500 PSI (310 bar)

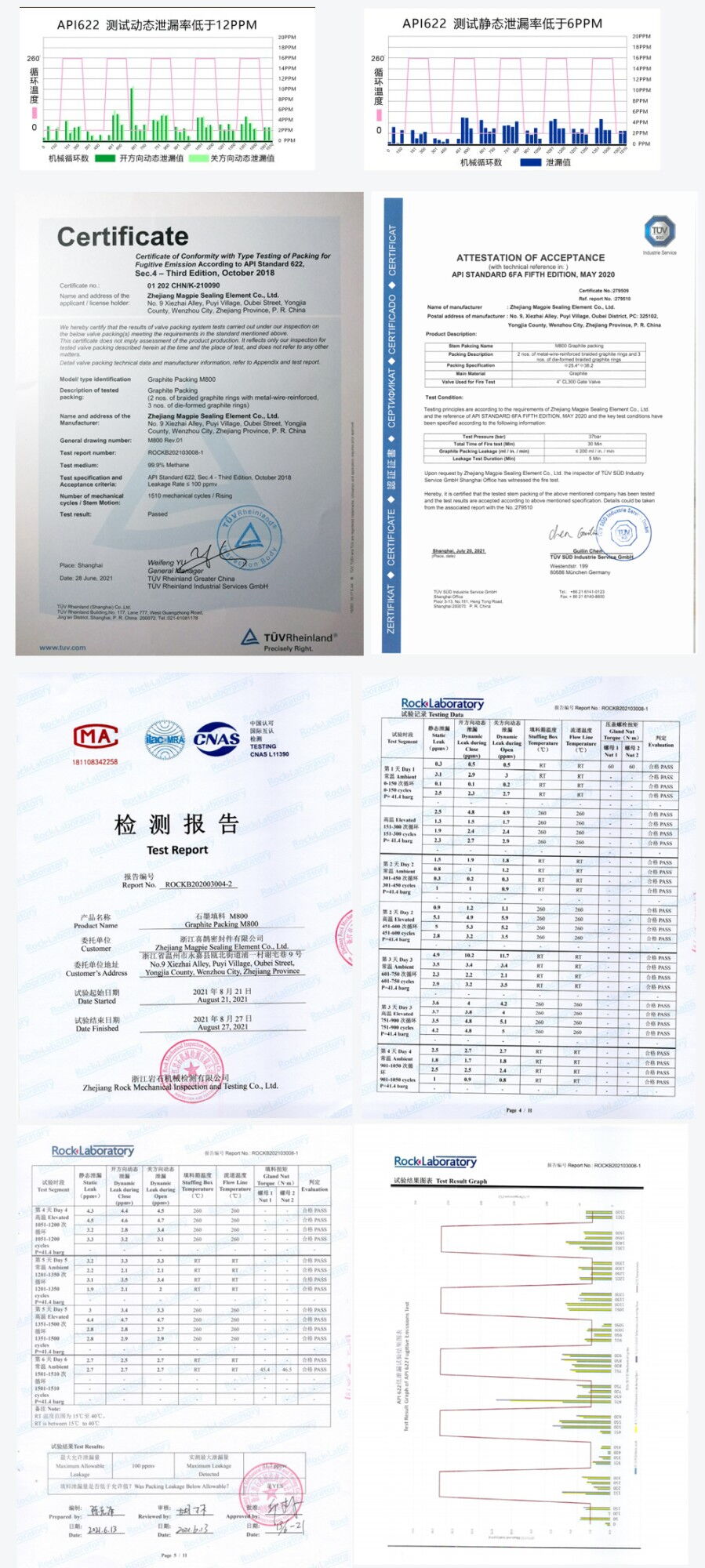

Certifications: API 622 (Second Edition) Low Emission, API 607

The API 622 test shows a dynamic leakage rate of less than 12PPM,

while the static leakage rate is less than 6PPM during the test.

API 622 TUV Experimental Data Report

Promotion Conference on Low-Leakage Graphite Packing Technology

The Demonstration of Low-emission Graphite Packing

We conduct life testing experiments on graphite packing in our factory

The ISO 15848-1 test of graphite packing at 400°C was conducted by a third-party testing institution

The promotion of our sealing products at the Valve Technology Forum