1. Excellent Corrosion Resistance: PTFE gaskets are highly resistant to a wide range of chemicals and corrosive substances. They can withstand pH values ranging from 0 to 14, with the exception of molten alkali metals and elemental fluorine under high-temperature and high-pressure conditions. This makes PTFE gaskets ideal for applications involving aggressive chemicals, acids, and bases.

2. Outstanding Aging Resistance: PTFE gaskets exhibit excellent resistance to aging. They do not absorb water and are unaffected by oxygen and ultraviolet light exposure. Even after three years of outdoor exposure, the tensile strength of PTFE remains almost unchanged, although the elongation may decrease slightly.

3. Good Mechanical Strength: PTFE gaskets maintain good mechanical strength within the temperature range of -100°C to 100°C. This allows them to be processed into various shapes and sizes, making them suitable for a wide range of applications.

4. Low Electrical Conductivity: PTFE is an excellent insulator, making PTFE gaskets suitable for applications where electrical insulation is required.

5. Non-Stick Surface: The non-adhesive nature of PTFE means that residues do not stick to the gasket, making cleaning quick and easy.

6. Electrical Insulation: PTFE gaskets offer excellent electrical insulation, making them ideal for applications where electrical isolation is critical.

PTFE (Polytetrafluoroethylene) gaskets are available in various types to cater to different sealing requirements across industries. Here are the main types of PTFE gaskets.

Virgin PTFE gaskets are made from pure PTFE without any fillers or additives. They exhibit exceptional chemical resistance, low friction, and broad temperature resilience, making them ideal for high-purity applications. These gaskets are non-stick and ensure minimal contamination, making them suitable for critical applications in chemical processing, food and beverage sectors, pharmaceuticals, and high-temperature environments.

Expanded PTFE gaskets are manufactured from a form of PTFE that has been expanded or stretched. These gaskets offer superior compressibility and conformability, making them ideal for uneven or damaged flange surfaces. They provide excellent chemical resistance and can withstand a wide range of temperatures, ensuring reliable sealing performance in various industrial applications.

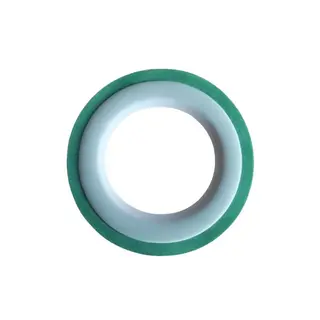

This type of gasket features a PTFE envelope encapsulating a compressed fiber insert. The combination of PTFE's chemical resistance and the fiber insert's mechanical strength offers enhanced durability and sealing performance. The non-stick surface of PTFE ensures easy maintenance, while the gasket's conformability allows it to adapt to irregular surfaces, making it suitable for demanding applications in petrochemical and chemical processing industries.

Glass-filled PTFE gaskets are composite materials that combine PTFE with glass microspheres or fibers. This combination enhances the gasket's mechanical strength, wear resistance, and dimensional stability. The presence of glass fillers reduces creep relaxation and improves the gasket's ability to conform to irregularities, ensuring a tighter seal. These gaskets are ideal for demanding applications in petrochemical, automotive, aerospace, and high-pressure sealing environments.

In the quest for environmental sustainability and regulatory compliance, industries are increasingly adopting stringent standards to minimize fugitive emissions. These standards not only help in reducing harmful pollutants but also enhance safety and operational efficiency. Here are some key standards that play a crucial role in achieving low emission goals:

ISO 15848 standardizes the measurement, testing, and evaluation procedures for industrial valve fugitive emissions. This standard is divided into two parts. ISO 15848-1 defines the test procedures for valve type testing, and ISO 15848-2 specifies the requirements for the manufacturing of valve products.

The German fugitive emission control law TA-LUFT VDI2440 defines the leakage rate, testing, and testing methods.

According to TA-LUFT and VDI 2440, the flange connection must meet the test pressure of 1 bar under the condition that the leakage rate is less than 10−4 mbar × l/(s × m). VDI 2200 specifies the selection, calculation, design, installation, and testing process of the flange connection. It also allows reference to VDI 2440 for the leakage rate. VDI 2200 also stipulates the burst pressure test to avoid the risk of flange breakage and sudden leakage.

The Clean Air Act stipulates that the maximum allowable leakage rate for valves, pumps, and agitators in the United States must comply with the EPA Method21 (blower method) for leakage testing, and the testing method must be consistent.

API 622 is the second edition of the international performance test for disk root materials, which includes temperature, pressure, thermal cycles, and mechanical cycles. API 622 specifies 1510 mechanical cycles and 5 thermal cycles, from room temperature to 260°C (500°F), pressure from 0 to 600 psi (0-41bar), for high-temperature testing. Under carbon equivalent testing, the allowable leakage rate is 100 ppm.

The first edition of the API 624 standard for the type test of the fugitive emission of the valve with a graphite seal includes the up and down motion and rotation of the valve, with a maximum diameter of 24 inches. The test requires the temperature to rise to 260°C (500°F) and perform 310 mechanical cycles and 3 thermal cycles, with the maximum allowable leakage rate being 100 ppm. The valve to be tested must first be tested according to API 622, and the temperature range is from -29°C to 538°C (-20°F to 1000°F).

Due to their unique properties, PTFE gaskets are widely used in the following industries:

Chemical Industry: For sealing corrosive chemicals and acids.

Petroleum Industry: For applications involving oils, fuels, and other petrochemical products.

Pharmaceutical Industry: For ensuring cleanliness and preventing contamination.

Food Industry: For applications where hygiene and non-toxicity are critical.

Aerospace and Automotive Industries: For their durability and resistance to harsh environments.

Selecting the right PTFE gasket involves careful consideration of several key factors to ensure compatibility, performance, and reliability in your specific application. Here are the essential factors to consider:

Understanding the specific application is crucial in selecting the appropriate PTFE gasket. Different industries and processes have unique requirements, and choosing a gasket that matches these needs ensures optimal performance and longevity. For example, food and beverage processing may require FDA-compliant materials, while chemical processing plants need gaskets with superior chemical resistance.

Evaluating the temperature and pressure conditions is vital to choosing a gasket that can withstand the operational demands. PTFE gaskets are known for their wide temperature range and ability to handle high pressures, but it's important to select a gasket that matches the specific temperature and pressure ranges of your application. This ensures the gasket maintains its integrity and provides a reliable seal under varying conditions.

Assessing the chemical environment ensures the gasket's longevity and reliability. PTFE is highly resistant to a wide range of chemicals, but certain applications may involve specific chemicals that could affect the gasket's performance. Understanding the chemical compatibility helps in selecting a gasket that will not degrade or fail over time.

Considering the application requirements and environmental factors aids in selecting the most suitable PTFE gasket type and material. Different types of PTFE gaskets, such as expanded PTFE, PTFE envelope with compressed fiber insert, virgin PTFE, and glass-filled PTFE, offer varying levels of performance and characteristics. Matching the gasket type and material to your specific needs ensures the best possible sealing solution.

Ensuring proper groove dimensions is essential for optimal sealing performance and preventing gasket failure. The dimensions of the gasket groove must be precisely matched to the gasket's dimensions to ensure a tight and secure fit. Proper alignment and fit prevent leaks and ensure the gasket operates effectively under the intended conditions.