Gasket fabrication for flanges, heat exchangers, and piping systems

Thermal shielding and heat dissipation in electronics

EMI/RFI shielding in sensitive equipment

Static sealing applications in oil & gas, chemical, and power industries

Excellent temperature resistance (up to 450°C in air, 3000°C in inert conditions)

Chemically inert to most media except strong oxidizers

High compressibility and conformability to irregular surfaces

Electrically and thermally conductive

Fire-safe and low-leakage performance

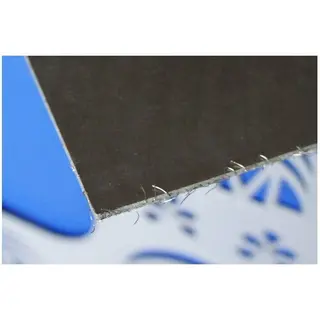

Flexible Graphite Sheet: Pure expanded graphite, easily conformable

Reinforced Graphite Sheet: Laminated with stainless steel foil, tanged metal, or mesh for strength

Oxidation-Inhibited Graphite: Enhanced resistance for high-temperature oxidizing environments

Composite Graphite Sheets: Bonded with PTFE or other materials for specialized applications

Braided into packing rings for valves, pumps, and agitators

Dynamic sealing in rotating or reciprocating equipment

Emission control in fugitive emission service (API 622, ISO 15848)

High-temperature sealing in power plants and refineries

Outstanding thermal resistance (up to 650°C in steam)

Low friction and self-lubricating, ideal for dynamic motion

Resistant to most chemicals across a wide pH range (0–14)

Flexible, resilient, and easy to braid or install

Can be reinforced for added strength and extrusion resistance

Pure Graphite Yarn: High-purity expanded graphite without additives

Wire-Reinforced Graphite Yarn: Typically reinforced with Inconel or stainless steel for high-pressure service

Graphite-PTFE Yarn: Combines low friction of PTFE with thermal stability of graphite

Carbon/Glass Fiber-Reinforced Graphite Yarn: Adds abrasion resistance and structural strength