Key Specifications / Features

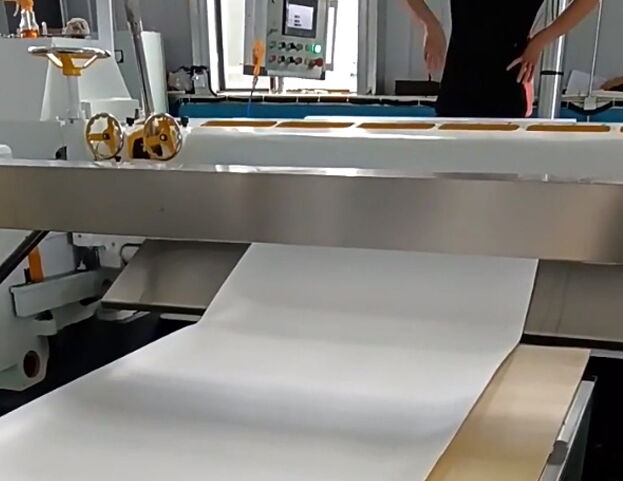

The Custom PTFE Sheet Supplier from China offers high-quality Polytetrafluoroethylene (PTFE) sheets tailored to meet specific customer requirements. These PTFE sheets are known for their self-lubrication and non-stick properties, making them versatile for a wide range of applications. Whether for industrial, automotive, or consumer use, these sheets provide durability, chemical resistance, and thermal stability, ensuring reliable performance in various environments.

- Model No.: MV-20250717-PS-01

- Hits: 17

- Categories: PTFE Gasket

- Tags: PTFE Sheet

Detail Information

Product Name: PTFE Sheet

Color: White

Material: PTFE

Customization: Support

Applications: Large pipelines, chemical industry, storage tanks

Polytetrafluoroethylene sheet (also known as PTFE sheet, Teflon sheet, or Fluoropolymer sheet) comes in two types: molded and skived. Molded sheets are produced by compression molding PTFE resin at room temperature, followed by sintering and cooling. Skived sheets are made by pressing PTFE resin into billets, sintering, and then peeling them into thin layers. PTFE sheets exhibit exceptional comprehensive properties:

- Resistance to extreme temperatures (-192°C to 220°C)

- Corrosion resistance (against strong acids, alkalis, aqua regia, etc.)

- Weather resistance

- High insulation

- High lubricity

- Non-stick properties

- Non-toxicity and harmlessness

Chemical Properties of Polytetrafluoroethylene (PTFE)

1. Insulation Properties

Unaffected by environmental conditions and frequency.

Volume resistivity up to 10¹⁸ ohm-cm, low dielectric loss, and high breakdown voltage.

2. Temperature Resistance

Minimal changes under temperature variations.

Wide operating range: -190°C to 260°C.

3. Self-Lubrication

Exhibits the lowest friction coefficient among plastics, making it an ideal material for non-lubricated applications.

4. Non-Stick Surface

Virtually no solid materials can adhere to its surface, as it has the lowest surface energy among solid materials.

Weather & Radiation Resistance, Low Permeability:

Maintains surface integrity and performance even after long-term exposure to the atmosphere.

5. Flame Resistance

Limiting Oxygen Index (LOI): Below 90 (highly flame-resistant).

Key Performance Characteristics

1. Non-Stick Property

Extremely low friction coefficient (about 1/5 that of polyethylene), a key feature of perfluorocarbon surfaces.

Weak intermolecular forces (fluorine-carbon bonds) contribute to its non-adhesive nature.

2. Mechanical Properties

Tensile Strength (σ₅): 20.7–27.5 MPa

Elongation at Break (δ): 250–350%

Impact Toughness (αₖ):

Notched: ≥16.1 J/cm²

Unnotched: >98.1 J/cm²

Tensile Modulus (E): ≥3.92 MPa

Hardness (Shore D): 50–65

3. Combustion Behavior

Maintains excellent mechanical properties across a broad range (-196°C to 260°C).

Unlike many polymers, it does not become brittle at low temperatures.

4. Electrical Properties

Low dielectric constant and dielectric loss over a wide frequency range.

High breakdown voltage, volume resistivity, and arc resistance.

5. Radiation Resistance

Poor resistance to high-energy radiation (degrades at 10⁴ rads).

Exposure leads to polymer degradation, significantly reducing electrical and mechanical performance.