In various industrial equipment and piping systems, sealing performance is directly related to operational safety, stability, and production efficiency. As a critical component for achieving reliable sealing, gaskets play an irreplaceable role in preventing media leakage, withstanding temperature and pressure fluctuations, and adapting to complex working conditions. Currently, graphite gaskets and PTFE gaskets are the two most widely used non-metallic sealing materials. With their unique physical and chemical properties, these gaskets hold an important position in industries such as chemical processing, power generation, food and pharmaceuticals, and mechanical manufacturing. A thorough understanding of their structural characteristics, performance differences, and applicable ranges is essential for scientific selection and improved sealing reliability. The following sections provide a systematic analysis from the perspectives of material properties, application fields, and performance comparisons.

Graphite gaskets are primarily divided into two categories: pure graphite gaskets and graphite composite gaskets. Each type features distinct structures, properties, and application scenarios, making them suitable for different industrial environments.

Pure graphite gaskets are sealing elements punched or cut from expanded graphite rolls or sheets. Their core advantage lies in material purity, expanded graphite contains no binders or fillers, resulting in extremely high purity.

- Core Performance Characteristics: Pure graphite gaskets offer outstanding corrosion resistance and can withstand the attack of most chemical media. They also possess good radiation resistance, making them valuable in specialized fields such as the nuclear industry. In terms of temperature adaptability, pure graphite performs exceptionally well, maintaining stable physical properties from ultra-low to extremely high temperatures. Specifically, flexible graphite can operate across a remarkably wide temperature range—from -270°C to 3650°C (in non-oxidizing gases) with minimal change in physical properties. Even when used in air, it can tolerate temperatures of approximately 450°C. This ultra-wide temperature capability surpasses many other sealing materials. Regarding chemical stability, flexible graphite exhibits excellent corrosion resistance to nearly all inorganic and organic media, except for strong oxidizing substances such as aqua regia, concentrated nitric acid, concentrated sulfuric acid, and high-temperature oxidizing salts like dichromates, permanganates, and ferric chloride. Pure graphite gaskets also feature unique self-lubricating properties. Similar to natural graphite, the layered structure allows interlayer sliding under external force, providing good lubrication, reduced friction, and a low friction coefficient. This helps prevent flange surface damage during installation and operation while maintaining sealing performance under dynamic conditions.

- Sealing Advantages: When shafts or sleeves exhibit radial runout due to manufacturing or installation eccentricity, pure graphite gaskets provide sufficient floating capability. Even if surface cracks appear, they can maintain tight conformity and prevent leakage. This adaptability significantly reduces flange surface machining requirements, allowing ideal sealing with relatively low preload.

- Installation and Maintenance: Pure graphite gaskets are easy to cut and can be fabricated into circular or complex geometric shapes. They can also be designed with inner and outer edge reinforcements, facilitating installation and removal while protecting the gasket from damage during service.

- Main Applications: Pure graphite gaskets are particularly suitable for low-pressure sealing and are widely used at flange connections in pipelines, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, and refrigeration equipment.

Graphite composite gaskets are manufactured by compressing expanded graphite particles with punched metal core plates or wire mesh. This structure combines the strength of metal with the sealing capability of graphite, making it suitable for more demanding conditions.

- Structure and Materials: These gaskets are typically stamped or cut from reinforced graphite sheets using specialized equipment. Common inner reinforcement materials include SS304, SS316 stainless steel, or tinplate, with thicknesses generally ranging from 0.05–0.2 mm. Depending on the reinforcement method, they can be classified into punched-plate reinforced, mesh-reinforced, and flat-plate reinforced composite gaskets. Edge wrapping is usually made from 304 or 316L stainless steel, preserving the gasket’s performance while simplifying installation and removal. The wrapped structure also prevents media and atmospheric oxygen from attacking the gasket, significantly improving temperature and pressure resistance.

- Performance Advantages: Compared with pure graphite gaskets, composite versions perform better under high-temperature and high-pressure conditions. They inherit graphite’s corrosion resistance, tolerance to extreme temperatures, radiation resistance, and excellent compressibility and recovery, while metal reinforcement greatly enhances mechanical strength. Composite graphite gaskets require lower preload than metal gaskets and spiral wound gaskets and impose less stringent flange requirements, making them an economical and practical sealing solution. They can be produced in various circular or complex geometries, such as level gauge gaskets, cylinder gaskets, exhaust gaskets, and ribbed heat exchanger gaskets.

- Specifications and Customization: There is virtually no limitation on maximum processing size, and special specifications or non-standard products can be customized according to customer requirements, enabling adaptation to diverse operating conditions.

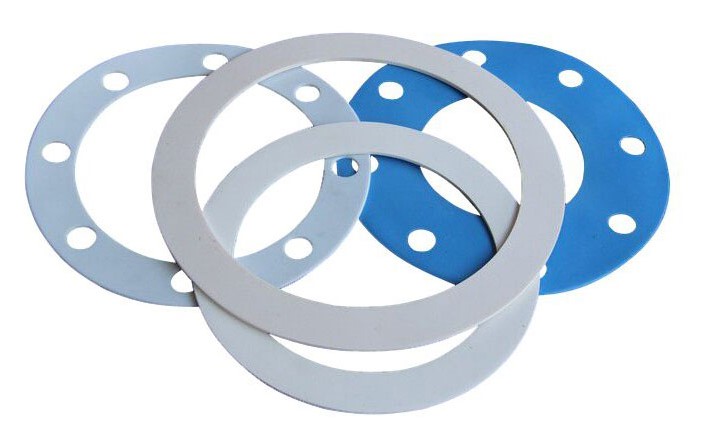

PTFE gaskets are sealing elements manufactured from PTFE resin through molding, turning, or cutting processes. Thanks to their distinctive performance combination, PTFE materials occupy a significant position in industrial sealing.

PTFE features an extremely low friction coefficient, outstanding chemical corrosion resistance, excellent non-stick properties, and a broad working temperature range (-80°C to +260°C). These characteristics enable PTFE gaskets to maintain reliable sealing performance and long service life in many extreme environments.

- Chemical Resistance: PTFE gaskets demonstrate exceptional chemical inertness, tolerating temperatures from -200°C to +260°C without sticking or aging. Suitable for static and some dynamic sealing applications, they do not absorb water or swell and maintain dimensional stability even under harsh conditions. This inertness allows them to resist nearly all chemical media, including strong acids, alkalis, and organic solvents.

- Temperature Adaptability: Although PTFE does not match graphite’s ultra-wide temperature range, its -80°C to +260°C capability satisfies most industrial needs while maintaining stable physical properties and sealing performance.

- Physical Characteristics: The non-stick nature of PTFE prevents adhesion to sealing surfaces, making maintenance and replacement easier. Its low friction coefficient reduces installation wear and extends the service life of both gaskets and flanges.

PTFE gaskets are available in multiple forms to meet varying application requirements:

- Pure PTFE Gaskets: Available in thin, medium, and thick specifications for static sealing of flat flanges.

- Filled Modified PTFE Gaskets: Reinforced with glass fiber, copper powder, graphite, or other fillers to improve mechanical strength, temperature resistance, or thermal conductivity. Common types include glass-filled and graphite-filled PTFE gaskets.

- Expanded PTFE Gaskets: Made from expanded PTFE, offering greater flexibility and resilience—ideal for uneven sealing surfaces and large flange connections.

- Special-Shaped Gaskets: Including irregular shapes, corrugated designs, and inner–outer ring combinations tailored to specific sealing surfaces and pressure ratings.

- PTFE Envelope Gaskets: Composite soft gaskets consisting of a PTFE sealing jacket with a non-asbestos or other non-metallic insert. They provide excellent corrosion resistance and compressibility, particularly for flat or raised-face steel pipe flanges.

- Expanded PTFE Sealing Tape: Similar in performance to expanded PTFE sheets but supplied in tape form with adhesive backing. It can be easily applied after removing the protective paper and achieves effective sealing with relatively low bolt force.

- Chemical Industry: Prevents leakage in equipment, reactors, storage tanks, and pipeline flanges, especially when handling corrosive substances such as strong acids, alkalis, and organic solvents.

- Food and Pharmaceutical Industries: Non-toxic, hygienic, and non-adsorptive properties make PTFE gaskets essential for ensuring product safety and quality.

- Power and Energy Sector: Used in equipment exposed to high temperature and pressure, including power plants and nuclear facilities, while also providing excellent electrical insulation.

- Precision Machinery: Preferred in high-precision sealing applications such as valves, pumps, precision mechanical components, and aircraft engines due to wear resistance, low friction, and stability at low temperatures.

- Temperature Adaptability: Graphite gaskets clearly excel, operating from -270°C to 3650°C (non-oxidizing environments) and about 450°C in air. PTFE gaskets, with a range of -80°C to +260°C, meet most standard requirements but are less suitable for extreme temperatures.

- Chemical Resistance: Both materials resist corrosion well, but graphite may be attacked by strong oxidizers. PTFE is inert to nearly all chemical media, giving it an advantage in highly corrosive environments.

- Mechanical Performance: Metal-reinforced graphite composite gaskets offer higher strength and pressure resistance, making them suitable for medium-to-high pressure service. Pure graphite is better for low pressure. PTFE generally has lower mechanical strength and may experience cold flow (creep), though fillers can significantly improve this property.

- Sealing Capability: Graphite provides excellent compressibility and recovery with low flange requirements. PTFE requires smoother, well-aligned flanges, though expanded PTFE improves adaptability to uneven surfaces.

- Installation and Maintenance: Both are easy to cut and install. Graphite’s self-lubrication protects flange surfaces, while PTFE’s non-stick nature simplifies removal.

- Cost-Effectiveness: Both are economical sealing materials. Graphite typically has lower raw material costs, while PTFE, despite sometimes higher upfront pricing, offers strong overall value due to durability and low maintenance needs.

When choosing between graphite and PTFE gaskets, consider the following factors:

Above 260°C, especially beyond 400°C, prioritize graphite—preferably composite graphite.

Within -80°C to +260°C, both are viable.

For ultra-low temperatures, graphite is more reliable.

Use PTFE for strong oxidizing substances.

Both materials handle general chemicals.

Graphite is advantageous in radiation-resistant applications.

Pure graphite for low pressure.

Composite graphite or filled PTFE for medium to high pressure.

Metal-reinforced graphite is ideal where mechanical shock or vibration exists.

Graphite adapts better to imperfect flange surfaces.

PTFE suits high-precision, smooth flanges.

Expanded PTFE works well for large or uneven surfaces.

Both meet hygiene standards, but PTFE is easier to clean.

Choose based on chemical compatibility in chemical processing.

Composite graphite is often preferred for high-temperature, high-pressure energy equipment.

Regardless of material, proper installation is essential:

Inspect flange surfaces for scratches or pits before installation.

Ensure gasket dimensions match the flange to avoid over-stretching or compression.

Tighten bolts in a diagonal sequence with gradual, even loading to prevent localized stress.

Carefully control preload for PTFE to prevent sealing failure caused by cold flow.

Regularly check sealing conditions and address leaks promptly.

Consider thermal expansion in high-temperature service and adjust preload accordingly.

Graphite and PTFE gaskets are both vital materials in industrial sealing, each offering distinct advantages and application ranges. Graphite gaskets stand out for their ultra-wide temperature tolerance, excellent self-lubrication, and low flange requirements, making them ideal for high-temperature, low-temperature, and moderately corrosive conditions. PTFE gaskets, with their exceptional chemical inertness and non-stick properties, are indispensable in highly corrosive environments and applications with strict hygiene standards.

In practical engineering, selecting the most appropriate sealing material requires a comprehensive evaluation of operating conditions, media characteristics, temperature and pressure requirements, and economic considerations. Proper selection not only ensures sealing reliability but also extends equipment service life, reduces maintenance costs, and enhances overall economic efficiency. As material technologies continue to advance, the application scope of both gasket types will further expand, providing increasingly reliable sealing solutions for industrial production.