This study focuses on comparing the performance of two major low-emission packing structures used in valve applications: V-type packing and flat-face packing. Both packing structures utilize composite packing consisting of graphite rings and braided packing.

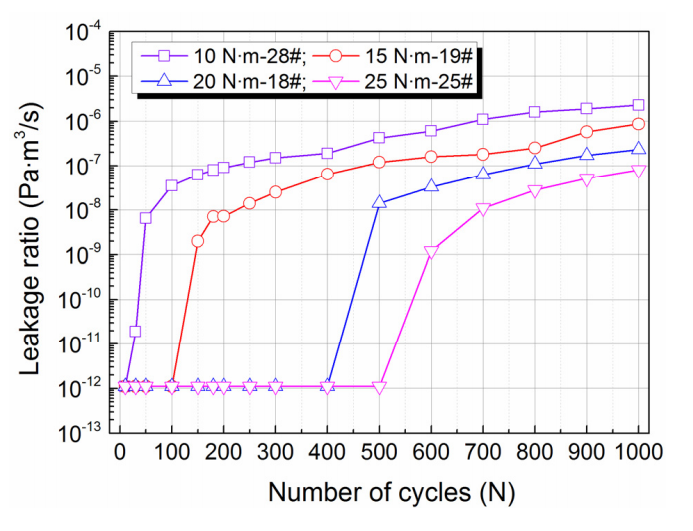

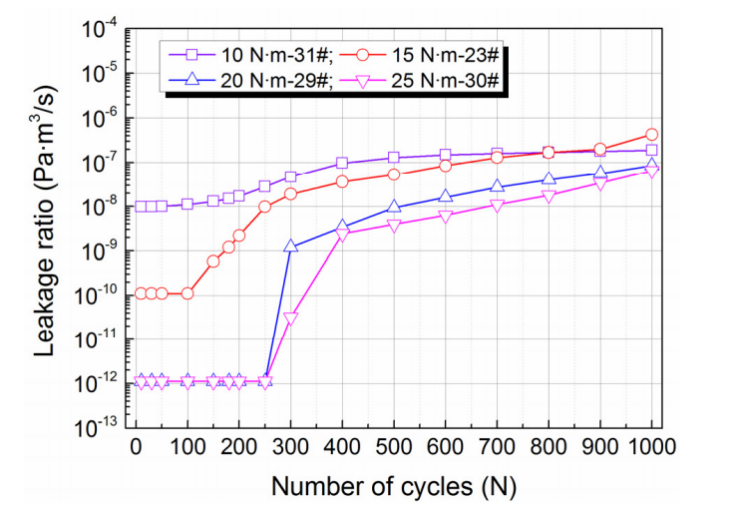

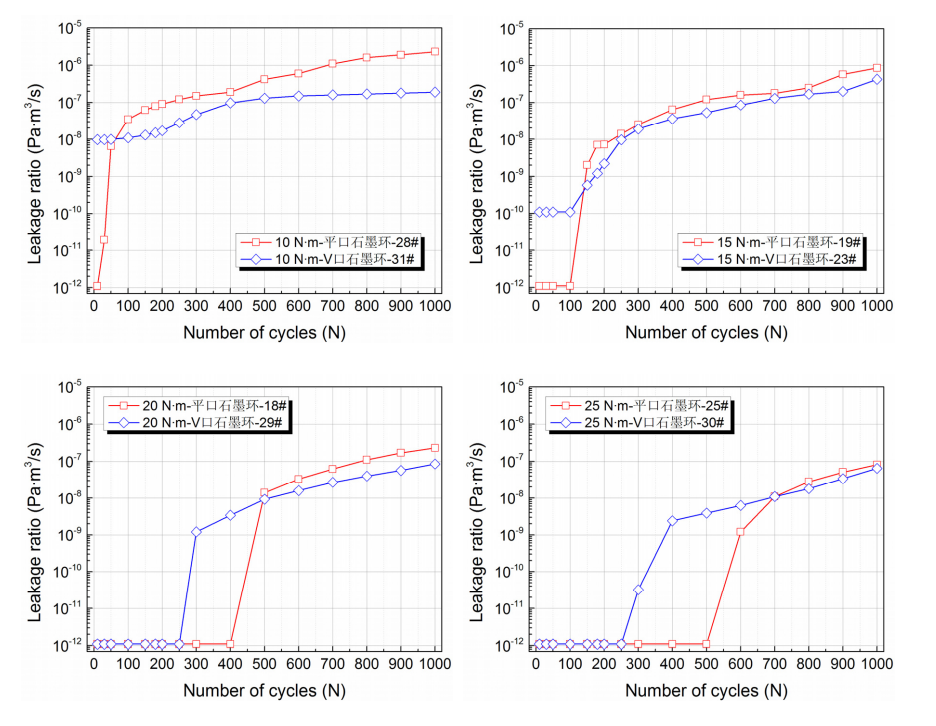

Figures 1 and 2 illustrate the change in leakage rate with the number of cycles under various single-side bolt torque conditions for both flat-face and V-type packing. As shown, increasing bolt torque, corresponding to higher sealing pressure, significantly reduces the leakage rate and delays the onset of high-leakage conditions.

Figure 1: Leakage rate of flat-face graphite/braided composite packing over cycles at different torques

Figure 2: Leakage rate of V-type graphite/braided composite packing over cycles at different torques

Compared to the flat-face packing, the leakage rate of V-type graphite packing is less sensitive to changes in bolt torque. This suggests that V-type structures may achieve effective sealing even under lower sealing pressures.

This is because the V-type geometry creates a line contact seal under light torque. Excessive torque, however, compresses the packing further, causing a shift from line sealing to surface sealing. Flat-face structures naturally rely on surface sealing, thus requiring a higher deformation torque for effective compression.

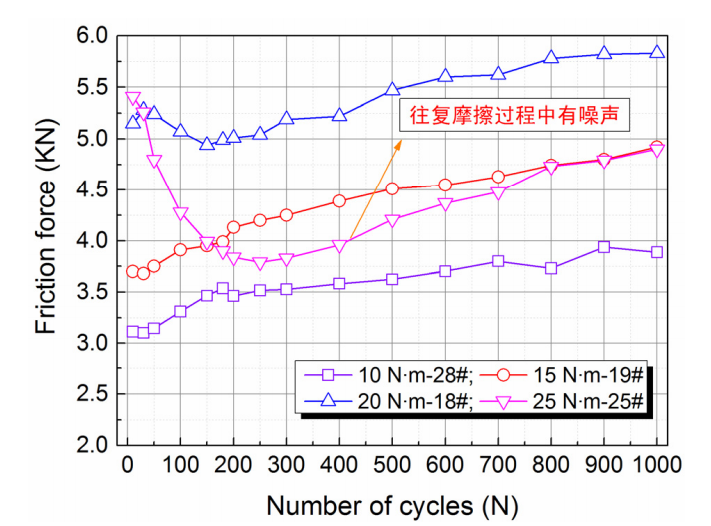

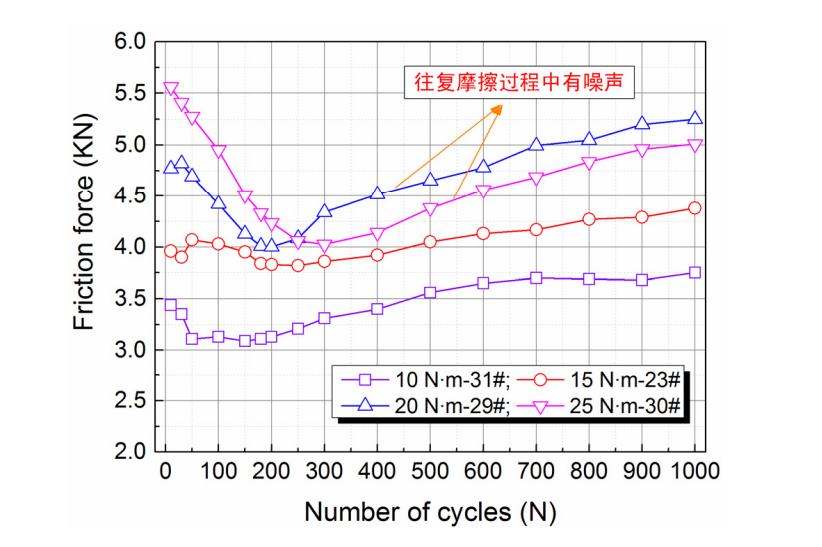

Figures below show how friction force evolves over cycles for both packing types under various single-side torque levels.

Flat-face packing at 25 N·m and V-type packing at 20 N·m and 25 N·m exhibited a pattern where friction decreased initially and then rose sharply within 200 reciprocating cycles.

Observations during testing noted audible noise during this phase, implying that friction-induced vibration may explain the dip and subsequent surge in friction force.

Under other test conditions, friction generally increased gradually over time.

Moreover, V-type graphite packing showed a slower rise in friction force and more stable performance throughout the test, while flat-face graphite packing tended to produce more noise and abrupt force spikes. This is due to the flat-face packing's lack of a friction buffer zone, which causes sudden energy release during motion.

The chart below compares the leakage rates of both packing types under single-side torques of 10 N·m, 15 N·m, 20 N·m, and 25 N·m. At all torque levels, flat-face graphite packing exhibited higher leakage rates than V-type packing, confirming that V-type graphite packings offer superior sealing performance.

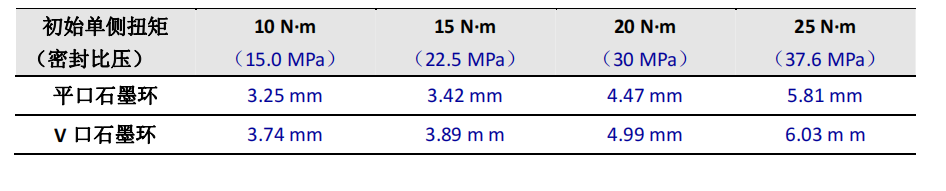

Additionally, V-type graphite rings compressed more than flat-face rings. The V-shape allows the sharp edge to deform and fill gland voids, enhancing radial sealing pressure and thus improving the overall seal integrity. The compressibility of V-type packings was consistently higher due to their radial expansion effect. This deformation compensates for internal gaps and reinforces the seal as torque increases.

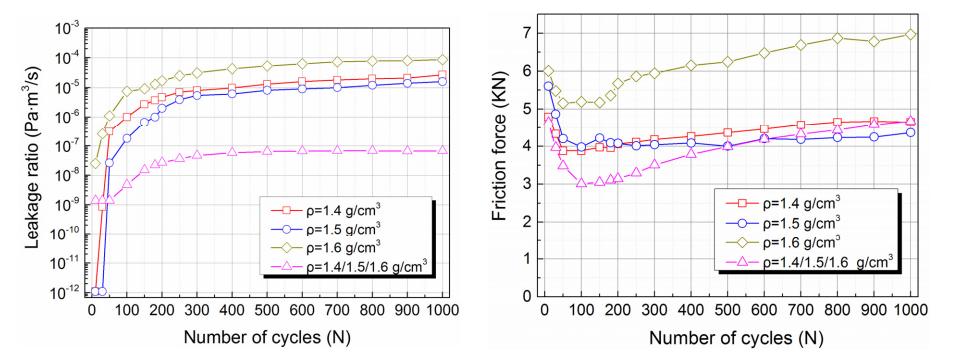

Graphite ring density plays a key role in both friction and sealing behavior:

Packing with ρ = 1.6 g/cm³ produced significantly higher friction than others.

Packing with ρ = 1.5 g/cm³ showed the most stable and lowest friction.

Variable-density packings had the lowest initial friction over the first 500 cycles and gradually increased, finally reaching slightly above that of the ρ = 1.5 g/cm³ packings.

Conclusion: The graphite ring density should not be too high or too low. When possible, variable-density graphite packing is recommended. For uniform density materials, a density of around ρ = 1.5 g/cm³ is optimal.

Through tribological and leakage rate testing of graphite/braided composite packings, the study analyzed the effects of sealing pressure, graphite ring geometry (flat vs. V-type), and density. Key conclusions are:

V-type graphite rings offer lower leakage rates and reduced friction, with more stable performance during reciprocation.

Graphite ring density significantly affects friction and sealing. Among densities of ρ = 1.4, 1.5, and 1.6 g/cm³, and variable-density options:

Variable-density composite packings provided the best sealing performance,

followed by ρ = 1.5 g/cm³.

Note: These results are based on lab conditions with high coaxiality and simplified environments. Real-world valve applications involve additional challenges such as stem movement, rotational forces, and thermal cycling. Thus, the practical performance differences between V-type and flat-face packings may vary. Future experiments will include more complex, realistic conditions.

Test Location: Zhejiang Rock Mechanical Inspection & Testing Co., Ltd.

Low-emission packing provided by: Zhejiang Magpie Sealing Co., Ltd.

Magpie Representative: Xie Heyi

Test Engineer: Guo Zhaohui