Magpie Sealing Technical Insight: Analysis & Mitigation of Flange Leakage in a Hydrogenation Reactor

In a catalytic reforming unit operated by a certain company, a flange at the top of the K201 pre-hydrogenation first-stage reactor began leaking after 2.5 years of continuous operation. The leakage gradually worsened over time. The reactor operates at a pressure of 2.45 MPa (working pressure 2.23 MPa) and a design temperature of 385°C (operating at 370°C). The working medium is hydrogenated oil (primarily C6–C9 hydrocarbons), with a corrosion allowance of 2 mm/year. The key material specifications are shown in Table 1.

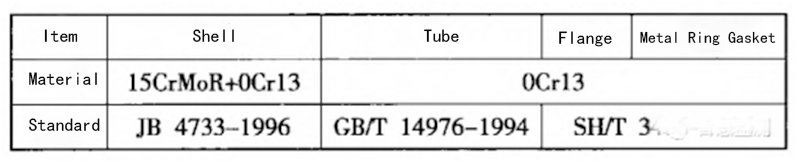

Table 1: Material Specifications of the K201 Pre-Hydrogenation Reactor

The leakage occurred at the top feed flange of the reactor. The flange bolts were M33x260mm, made of 35CrMoA/35CrMo.

As shown in Figure 1, the elliptical metal ring gasket had discontinuous contact with the ring groove surface, forming localized gaps. These discontinuities allowed a sealing gap to develop between the gasket and the mating surface, leading to leakage.

Figure 1: Feed Flange of the Reactor

Flange leakage can result from several factors, including the properties of the sealed medium, operating conditions, flange surface roughness, bolt preload, gasket quality, size, and assembly history. In another hydrogenation unit, flange cracks developed under high temperature and pressure due to dissimilar metal welds.

In the case of this reactor, the metal gasket installed during the previous shutdown had operated without issue for 2.5 years. Since the medium and flange design remained unchanged, the analysis focused on changes in operational conditions:

The reactor experienced approximately 20 startup/shutdown cycles since the last maintenance. Under fluctuating temperature and pressure, the gasket underwent fatigue, leading to leakage.

Prolonged high temperatures caused bolt and gasket creep, reducing the sealing stress. Bolt elongation and flange deformation also contributed to reduced sealing load, triggering leakage when residual stress dropped below the minimum required.

Once leakage occurred, the high-pressure medium eroded the sealing surface, forming radial pits and worsening the leakage.

Minimize unplanned shutdowns and rapid temperature changes to reduce thermal gradients in the reactor.

During shutdowns, flushing hydrogen into the fresh feed and circulating oil lines must be done slowly to prevent flange leaks from sudden cooling. If leakage occurs, steam purging should be performed immediately to prevent fire.

During startup, thermal expansion can cause slight leakage at the flange and gasket interface. Place steam hoses at the leak points to disperse oil vapors and prevent fire hazards. To reduce thermal stress, the heating rate should not exceed 25°C per hour.

After overhaul or during the first startup, all bolts installed at ambient (cold) conditions experience thermal expansion during operation, which must be accounted for.

Figure 2: Real-Time Online Monitoring and Prevention of High-Temperature Oil and Gas Flange Leakage

Due to localized erosion of the sealing ring face, repair must comply with the Safety Technical Supervision Regulation for Pressure Vessels. The nozzle flange, connected to the equipment body, can be repaired onsite using specialized tools. Figure 3 shows the repair setup, which includes a support plate, central shaft, and cutting tool holder.

Figure 3: Onsite Flange Repair

For hydrogenation reactors operating within high-temperature ranges, selecting a high-performance gasket is crucial. Combining this with precision torque tightening, digital quality assurance during flange assembly, and real-time monitoring of the sealing status significantly enhances reliability.

Additionally, using high-temperature-resistant bolts is key to maintaining minimal or negligible leakage levels through an entire overhaul cycle, thereby reducing energy loss, pollution, and improving operational safety.

Real-time monitoring of flange sealing status and leakage trends helps enterprises track equipment health and prevent safety risks. Magpie Sealing, in collaboration with Huigan IoT (Shanghai), offers such monitoring services. The system provides scientific recommendations for hot-tightening timings, reducing equipment failure risks and ensuring safer production.

After repairing the flange and replacing it with a new elliptical metal ring gasket, onsite lapping and pressure/gas-tightness testing confirmed the system was leak-free. Throughout the subsequent overhaul cycle, no leakage occurred. Upon disassembly during the next scheduled maintenance, the flange sealing surface remained in good condition.

For any technical questions about industrial sealing, feel free to follow Magpie Sealing and reach out for consultation or leave a comment. Thank you for reading! In our next issue, we’ll continue exploring different sealing gasket types. See you next time!