Magpie Sealing Technology Sharing

Typical Sealing Applications: Common Sealing Forms of Industrial Valves

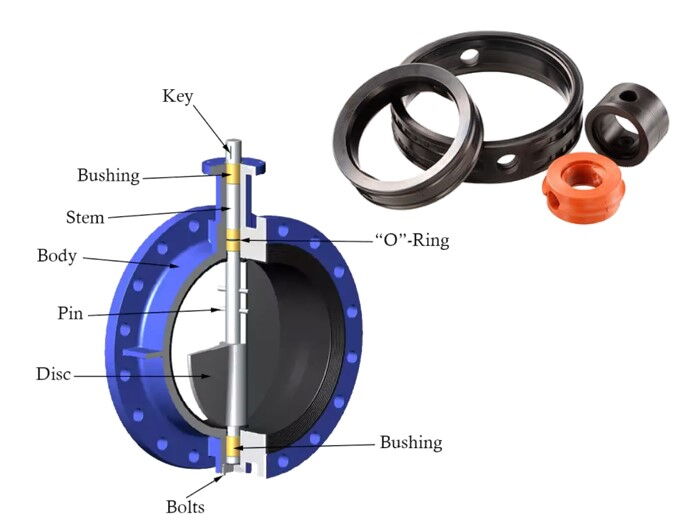

In addition to the ball valve seat sealing discussed in the previous issue, the seat sealing design of butterfly valves also presents unique characteristics.

The triple-eccentric butterfly valve is a commonly used valve type in modern industrial applications. Its distinctive design and excellent performance make it a key component in fluid control systems.

This valve adopts a radial sealing method, meaning the sealing occurs along the diameter direction of the disc. It offers excellent sealing performance and low leakage, capable of stable operation under high pressure, high temperature, and corrosive environments. The sealing surface and sealing angle require special machining for optimal performance.

Nozzle Flange Sealing

In valve sealing, the final stage involves the nozzle flange, as mentioned in previous sealing courses. It mainly uses three sealing methods: face sealing, line sealing, and quick sealing, all of which play a critical role in ensuring tight sealing at the valve's nozzle connection.

Face sealing refers to the sealing achieved at the contact surface between the gasket and the valve flange. It has good sealing performance and effectively prevents medium leakage.

This is typically realized using gaskets placed between the flanges. Common gasket materials include flexible graphite, rubber, and PTFE, all known for their sealing capabilities. Face sealing is widely used in valve, pipeline, and equipment connections.

Line sealing, also known as linear sealing, is a sealing form where the contact between the seal and flange is linear. It is characterized by high reliability and stable performance under harsh conditions such as high temperature and high pressure.

Common components used include metal sealing rings and spring-energized sealing rings. Line sealing is increasingly popular in the valve industry and is becoming the preferred sealing method for many products.

Quick sealing enables fast connection and disassembly, making it ideal for scenarios where the sealing element must be frequently replaced. This method typically uses threads, snap-fit mechanisms, or other quick-connect structures, offering easy disassembly and good sealing performance. It is widely applied in valves, pipelines, and pressure-containing equipment.

As shown in the diagram, the body-bonnet flange sealing is structurally similar to the forced flange sealing commonly used. It relies on pre-tightening bolts to provide compressive force between sealing surfaces, thereby achieving the sealing function.

This sealing method is particularly critical in high-pressure valves, as the medium pressure enhances the sealing stress, maintaining sealing integrity as internal pressure increases.

The flat face flange connection of the body and bonnet typically uses the MF flange form, where the valve body adopts a female face flange (FM), and the bonnet adopts a male face flange (M).

In practice, the FM and M combination provides excellent sealing, particularly in high-pressure environments. The FM face accommodates the gasket, while the M face applies the necessary compression.

Common gaskets for this structure include:

- Spiral wound gaskets

- Corrugated metal gaskets

- Pure graphite gaskets

- Reinforced graphite gaskets

The choice depends on operating conditions, medium characteristics, pressure level, and temperature rating.

The body-bonnet flange can also utilize various line sealing structures, such as C-ring seals or O-ring seals. The advantages of this approach include:

- Improved sealing tightness

- Reduced radial dimensions

- Lighter flange weight

- More compact and lightweight valve design

This structure optimizes valve construction and enhances performance and reliability across diverse working conditions.

Another form of sealing in body-bonnet flanges is self-tightening sealing, similar in principle to the traditional Wood-type seal ring. While such seals previously used soft metals, advancements in sealing technology have led to increasing use of trapezoidal-section graphite self-tightening seal rings.

Under the initial preload from bolts and the pressure of the process medium, the sealing stress increases as medium pressure increases, making this sealing method particularly effective for high-pressure valve applications.

Magpie Sealing continues to provide reliable solutions for low-leakage sealing needs. If you have questions about sealing technologies, feel free to follow us, leave comments, or reach out for consultations. Thank you for reading. In the next issue, we will continue our discussion on sealing gasket forms. See you next time!