Magpie Sealing Technology Insight

Flange and Gasket Standards (Part 1): Standards for Flanges and Gaskets

In previous discussions, we explored the various types of flange sealing faces, each with unique applications and benefits. In this issue, we provide a brief overview of the standards that govern flanges and gaskets.

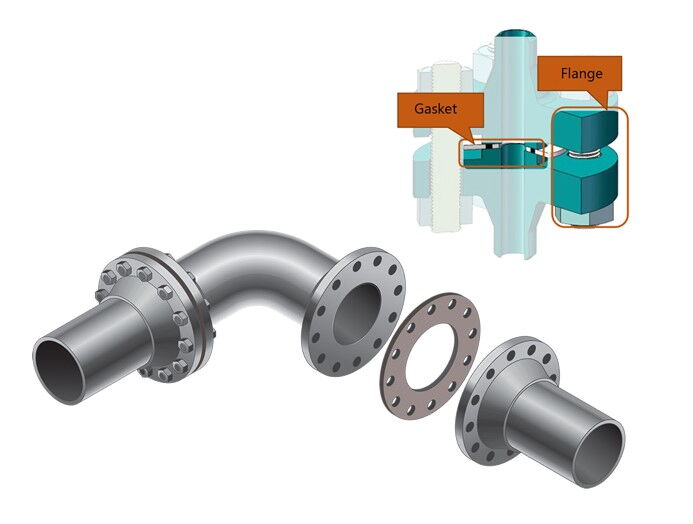

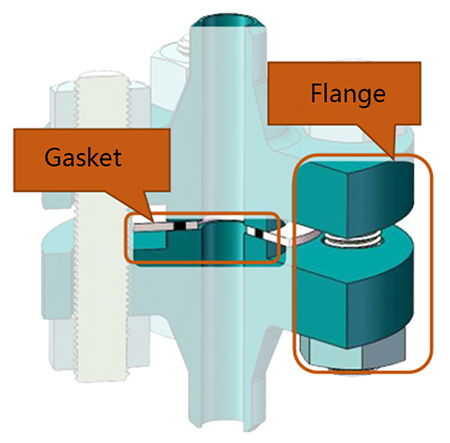

Flanges are essential connection components used in piping systems to join and seal sections of pipe. Gaskets, placed between flanges, enhance sealing performance and prevent leakage. To ensure the effective function of both flanges and gaskets, it is crucial not only to adhere to relevant standards but also to consider multiple design factors. Thoughtful selection and engineering are key to guaranteeing long-term system reliability and operational safety.

Flanges and gaskets play a vital role in maintaining process stability and operational safety. To guarantee interchangeability, compatibility, and reliability, standardized systems have been developed. These systems include specifications for technical conditions, structural dimensions, materials, inspection protocols, and testing requirements, both in China and internationally.

Flange and gasket dimensions and pressure ratings are defined based on nominal diameter and nominal pressure. Ensuring that specifications and performance meet established standards is critical. This standardization simplifies production and maintenance, enhances product consistency and dependability, and supports easier selection and application. As a result, series design has been widely adopted across industrial manufacturing and mechanical engineering fields.

Flange and gasket standards vary globally. The U.S. follows ASME, ANSI, ASTM, and API standards; the UK uses BS; Germany applies DIN; Europe adheres to EN; and Japan employs JIS and JPI systems. Together, these frameworks reflect the diversity and depth of global standardization efforts.

In China, standards such as GB, JB, HG, SH, and NB are commonly used. On the international level, organizations like the International Organization for Standardization (ISO) play a key role in advancing unified standards. ISO standards enjoy widespread recognition and implementation worldwide, offering strong guidance on product quality, safety, and environmental compliance.

If you have questions about sealing technologies or are facing technical challenges, follow Magpie Sealing for professional insights. We welcome your inquiries, comments, and feedback!

Stay tuned for the next installment, where we’ll continue exploring different types of sealing gaskets. See you next time!