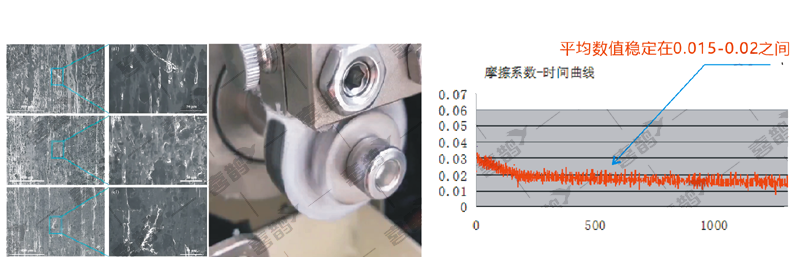

Magpie Valves has successfully developed PTFE packing with an ultra-low coefficient of friction of 0.01–0.02 for oxygen-enriched environments.

In the fields of materials science and valve manufacturing, materials with an ultra-low coefficient of friction of 0.01-0.02 have long been a technical barrier that is difficult to overcome. These materials with ultra-low coefficient of friction are primarily used in high-end control valves, such as those used in nuclear power plants. Such valves require stringent long-term stability and ultra-low friction. Only by using these materials can the control valves achieve ultra-high precision, ensuring the safe and stable operation of nuclear power systems.

In dry environments, the coefficient of friction between PTFE (polytetrafluoroethylene) and steel typically ranges from 0.05 to 0.1. As the temperature increases, the coefficient of friction of PTFE decreases accordingly. This is because higher temperatures cause an increase in the molecular spacing of PTFE, which in turn reduces friction. However, as the temperature rises, PTFE will quickly exhibit creep behavior. PTFE is a typical polymer material with cold flow properties, and its creep issue is particularly critical in certain applications.

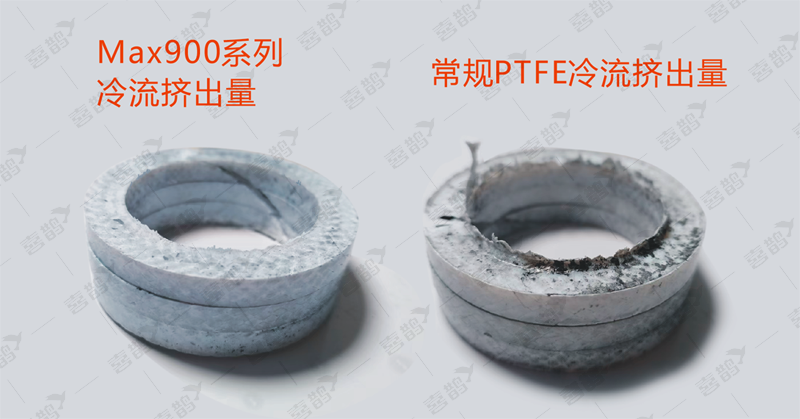

For example, after the PTFE packing is preloaded with high-strength bolts, the degree of PTFE creep will be influenced by various factors during continuous valve operation. Higher compressive stress, more frequent valve cycling, and elevated temperatures all contribute to increased PTFE creep. Additionally, the crystallinity of PTFE significantly affects the amount of creep. When the crystallinity is between 50% and 70%, the creep strain remains below 2.4%. However, if the crystallinity is below 55% or above 80%, the creep strain increases rapidly.

Our MAX900 PTFE packing demonstrates outstanding resistance to creep and cold flow, effectively preventing deformation issues caused by material properties. At the same time, it offers excellent low-leakage sealing performance, closely fitting the internal structure of the valve and significantly reducing the risk of media leakage. This dual advantage ensures the stability of the valve during prolonged use, maintaining reliable operation and optimal performance even with frequent cycling or long-term operation.