Magpie Valve Selection: Accurate Matching Ensures Reliable Control

Valve Technology Sharing

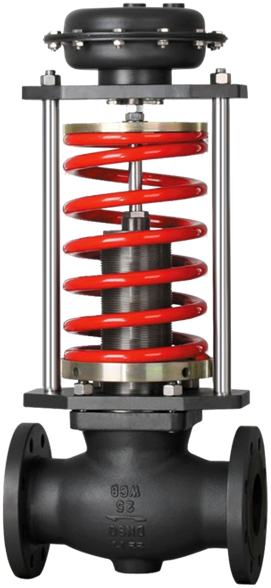

Characteristics and Applications of Self-Acting Pressure Reducing Valves

In today's industrial sector, especially in gas transmission and utilization systems, ensuring the stability and safety of gas pressure is of paramount importance. The self-acting pressure reducing valve, as an efficient and reliable device, has become the preferred choice in many application scenarios due to its unique design and superior performance. This article will delve into the core parameters, working principles, product advantages, and application considerations of self-acting pressure reducing valves, aiming to provide users with comprehensive references to help them better understand and apply this efficient device.

Outstanding Pressure Reduction Ratio: The pressure reducing valve has an inlet pressure of up to 6 kg (0.6 MPa), while the outlet pressure is stably maintained at 10 kPa. The pressure reduction ratio is approximately 60, which far exceeds that of conventional pressure reducing valves (usually with a pressure reduction ratio of ≤10). This makes it specifically designed for high-pressure differential pressure reduction needs, such as in the process of reducing gas pressure from the distribution network to end-use equipment, where a significant pressure drop is required.

Application Scenarios: It can be directly adapted to end-use equipment such as gas engines and boilers, effectively solving the stable pressure regulation problem from medium-pressure gas (0.6 MPa) to low-pressure working conditions (10 kPa). This prevents high-pressure surges from damaging the equipment, ensuring its safe and stable operation.

Large-Diameter Diaphragm Actuator: To address the challenges posed by the ultra-high pressure reduction ratio, the pressure reducing valve significantly increases the diaphragm area, which is 30% to 50% larger than that of conventional products. By increasing the diaphragm thrust (which is proportional to the diaphragm area and inlet pressure), the following functions can be achieved:

When the outlet pressure fluctuates (for example, due to changes in flow caused by equipment start-up or shutdown), the actuator can quickly respond and accurately push the valve core to adjust, thereby maintaining the stability of the outlet pressure (within the range of 10 kPa ± deviation);

When there is no flow at the downstream end (such as when the equipment is shut down), the strong diaphragm thrust can drive the valve core to close tightly, effectively preventing the leakage of high-pressure gas from the inlet. In high-pressure differential scenarios, sealing is a core safety requirement.

The pressure reducing valve does not require external power (electricity or air) but relies on the pressure of the medium itself to achieve balance:

High-Pressure Inlet End: The pressure is transmitted to the upper cavity of the diaphragm actuator through a pressure guide tube, forming a balance with the spring force in the lower cavity of the actuator and the feedback pressure from the low-pressure outlet end;

Pressure Regulation Process: When the inlet pressure rises or the outlet flow decreases, the outlet pressure will temporarily increase, which in turn causes the pressure in the lower cavity of the diaphragm to rise, pushing the diaphragm upwards, closing the valve core, reducing the flow, and ultimately bringing the outlet pressure back to the set value (10 kPa);

Core Challenge Response: Under high-pressure differential conditions (0.6 MPa → 10 kPa), the thrust of ordinary diaphragm actuators is often insufficient, leading to problems such as "inability to close tightly and unstable regulation." Therefore, it is necessary to increase the diaphragm area to enhance the thrust (thrust = diaphragm area × (inlet pressure - outlet pressure)) to ensure that it can balance the valve core resistance brought by the high-pressure differential.

Material Compatibility: The diaphragm uses a nitrile rubber/fluororubber composite membrane that is resistant to gas corrosion, with characteristics of anti-aging and prevention of gas permeation. The valve body and internal components are made of stainless steel or cast steel, which can effectively resist medium-pressure erosion, ensuring the stability and durability of the equipment in a gas environment;

Safety Redundancy: The pressure reducing valve is equipped with an overpressure cut-off device (optional). When the outlet pressure exceeds the set value due to a fault (for example, reaching 15 kPa), the mechanical structure will automatically cut off the gas flow to avoid risks to the equipment due to overpressure. This is an extremely important safety requirement in gas scenarios.

As a single-stage pressure reducing valve, it can achieve a pressure reduction ratio of 60:1, thus replacing the traditional "multi-stage pressure reduction" solution. This not only saves pipeline space but also reduces the overall system cost, eliminating the need for multi-stage valve series connections and providing customers with a more efficient and economical solution.

Thanks to the strong thrust provided by the large diaphragm actuator, the outlet pressure fluctuation of the pressure reducing valve can be controlled within ≤±5%. During shutdown, the leakage rate is even ≤0.1% of the rated flow. This performance far exceeds the industry standard and fully meets the strict requirements of gas equipment for "pressure stability + zero leakage," ensuring the safe operation and efficient production of the equipment.

Due to its self-acting structure, the pressure reducing valve does not require electric or pneumatic components and relies entirely on mechanical force to achieve balance. In gas (clean medium) scenarios, it requires almost no maintenance, significantly reducing maintenance costs. In contrast, electric pressure reducing valves require regular calibration and transducer maintenance, while this self-acting pressure reducing valve eliminates these cumbersome maintenance tasks, saving customers time and effort.

The pressure reducing valve is specifically designed for medium-pressure gas scenarios with an inlet pressure of 0.6 MPa and has passed the gas industry's explosion-proof certification (such as ATEX, GB 50028). It can be directly connected to urban gas networks or industrial gas systems, providing customers with a convenient and reliable gas pressure reduction solution without the need for additional adaptation and modification.

Installation Direction: During installation, it is essential to ensure that the diaphragm actuator is vertically upward to prevent diaphragm displacement from affecting the thrust. Additionally, it is recommended to install a filter at the inlet end with a filtration accuracy of ≥50μm to prevent impurities from entering the valve core, causing sticking phenomena, and affecting the normal operation of the equipment.

Commissioning Key Points: Although the pressure reducing valve has been pre-adjusted to an outlet pressure of 10 kPa before leaving the factory, it is still necessary to perform secondary calibration under no-load and full-load conditions after on-site installation. By adjusting the spring adjustment screw on the top of the actuator, the pressure can be fine-tuned to ensure the stability of the outlet pressure at different flow rates, meeting the requirements of actual working conditions.

In summary, the self-acting pressure reducing valve, with its ultra-high pressure reduction ratio, excellent pressure stability and sealing performance, maintenance-free design, and good scenario adaptability, has become the ideal choice for medium-pressure gas scenarios. By installing and commissioning it properly, the device can effectively ensure the safety and efficient operation of gas systems, bringing significant economic benefits and safety guarantees to users.