Magpie Valve Selection: Accurate Matching Ensures Reliable Control

Valve Technology Sharing

Control Types and Core Wire Configurations of Electric Actuated Valves

A Comprehensive Guide to Electric Actuated Valve Control Modes and Signal Wiring: From Basic On-Off Control to Smart Modulating Systems

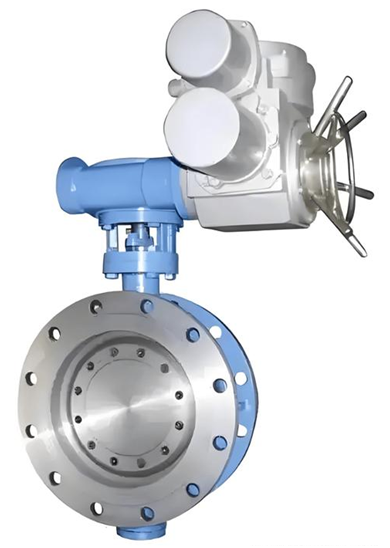

In the field of industrial automation, electric actuated valves serve as essential actuators for fluid control. Their control types and signal wiring configurations directly impact system stability and automation sophistication. From simple open/close operations to advanced modulating functions, electric actuated valves vary significantly in power requirements, signal wire counts, and functional modules. This article offers a systematic breakdown of electric actuated valve classifications and wiring logic, revealing the secret behind each configuration.

Power Supply Options:

Single-phase AC 220V: Two-core (Live + Neutral); suitable for small-diameter valves (DN ≤ 50) or low-pressure systems.

Three-phase AC 380V: Three-core (Three Live wires); for large-diameter valves (DN ≥ 100) or high-torque demands (e.g., high-pressure ball valves).

Control Signal (Three-Core Logic):

Open (Forward): Activates motor to open the valve.

Close (Reverse): Reverses motor direction to close the valve.

Common (COM): Shared return line (Neutral or center point).

Feedback Signal (Optional):

Without Feedback: Only 3-core wiring for basic open/close control, suitable where no position monitoring is required.

With Feedback (6-core setup): Adds position feedback via dry contacts (Open limit / Close limit / COM) using micro-switches; enables valve position monitoring through PLC or DCS systems.

Extended Features:

Overload alarm, travel limit protection, and status indicator lights (e.g., red/green for open/closed).

Local/Remote switch support via panel buttons or signal input for on-site commissioning.

Increased Core Count:

Power + Control + Feedback + Alarm typically requires 10–12 wires. If a communication module (e.g., Modbus) is integrated, two extra cores are needed.

Power & Control Signals:

Power: AC 220V (2-core) or AC 380V (3-core).

Input: 2-core analog signal (e.g., 4–20mA for 0–100% valve position).

Feedback (Optional): 2-core analog output (4–20mA) for position feedback, forming a closed-loop system.

Key Characteristics:

No "open/close" direction—positioning is handled by variable motor speed.

Ideal for continuous regulation of flow or pressure, such as in thermal oil control valves.

Feature Enhancements:

Built-in smart positioner supporting HART/Modbus/Profibus protocols for remote configuration.

Real-time diagnostics for torque, temperature, and phase loss, with fault alarm output.

Power-off memory function retains valve position and restores it on reboot to prevent process disruptions.

Typical Wiring (e.g., 16-core):

Power: 2-core (220V) or 3-core (380V)

Control: 2-core input + 2-core feedback (4–20mA)

Communication: 2-core (e.g., Modbus)

Alarms: 4–6 cores for overload, overheating, or limit alarms

Redundancy: 2–4 extra cores reserved for future upgrades (e.g., position transmitter).

|

Valve Type |

Power |

Control Signal |

Feedback |

Alarm/Communications |

Total Cores |

Typical Applications |

|

Basic On-Off (No Feedback) |

AC 220V |

3 cores (Open/Close/COM) |

None |

None |

3 cores |

Manual/semi-auto systems (e.g., water tank inlet) |

|

Basic On-Off (With Feedback) |

AC 220V |

3 cores |

3 cores |

None |

6 cores |

Monitored pipelines (e.g., gas shut-off) |

|

Standard Modulating |

AC 220V |

2 cores (4–20mA input) |

2 cores |

None |

4 cores |

Simple flow control (e.g., cooling water) |

|

Smart On-Off |

AC 380V |

3 cores |

3 cores |

2 cores |

8 cores |

High-pressure systems (e.g., overpressure shutoff) |

|

Smart Modulating |

AC 380V |

2 cores |

2 cores |

6 cores |

12+ cores |

Advanced automation (e.g., chemical reactor control) |

Key Wiring Rules:

- Power Cores: 2 for single-phase, 3 for three-phase.

- Control Cores: 3 for open/close, 2 for analog modulation.

- Feedback & Alarms: Each added feature typically requires 1–2 extra cores.

- Redundancy: For industrial applications, 20% spare capacity is advised (e.g., use 16-core cable for 10-core demand).

Basic On-Off: If only open/close is needed, choose basic on-off models (3–6 cores). For hazardous media, add alarms (e.g., chlorine service).

Continuous Modulation: For 0–100% control, go for modulating types. Basic models with 4 cores handle closed-loop control, while smart models (12+ cores) enable full digital integration.

Explosion-proof Areas: Use explosion-proof actuators and shielded cables. Include grounding cores.

Outdoor Installations: Prefer smart models with anti-moisture coatings. Add cores for heating if required (e.g., 2-core for electric trace heating).

Case 1: A 3-core on-off valve was wired with a 6-core cable, but feedback wires left unconnected. DCS couldn't detect valve status, leading to a leak.

Case 2: A smart modulating valve was wired with only 10 cores, lacking communication lines. It couldn't be integrated into the plant's IoT system, resulting in costly rewiring.

The number of wires in an electric actuated valve is the physical mapping of its function — from a basic 3-core system to a complex 16-core smart network. Each core carries not just electricity or signal but also the "neural network" of industrial automation. Understanding the underlying logic, power determines supply cores, control precision drives signal cores, safety demands redundant cores, helps avoid overengineering or under-equipping.

Next time you face an electric actuated valve wiring task, ask yourself three questions:

- Is it on-off or modulating?

- Do I need feedback or alarms?

- Will I need communication in the future?

Answer those, and the core configuration will naturally follow. For customized valve selection or wiring strategies tailored to specific scenarios, feel free to reach out, and ensure every wire serves your process with precision.