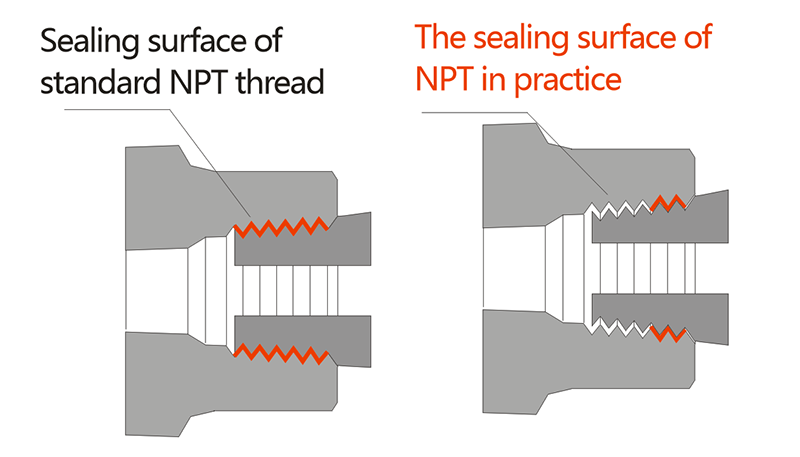

The issue of counterfeit NPT threads often goes unnoticed during third-party inspections. NPT (National Pipe Taper) threads are widely used in various components of valves, such as both valve ends, pressure relief valves on ball valves, and drain valves. While Teflon tape or sealant is often used to assist in sealing, the quality of the threads themselves remains critical.

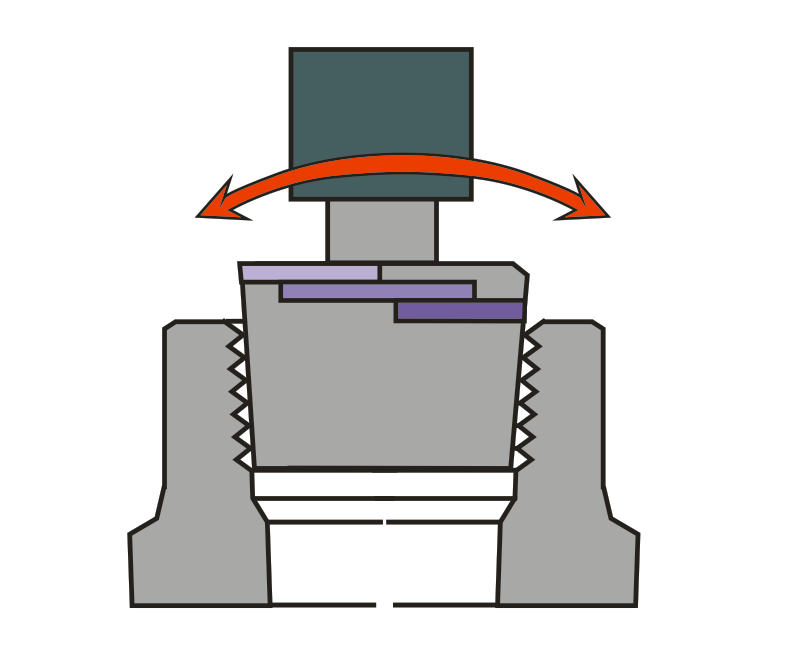

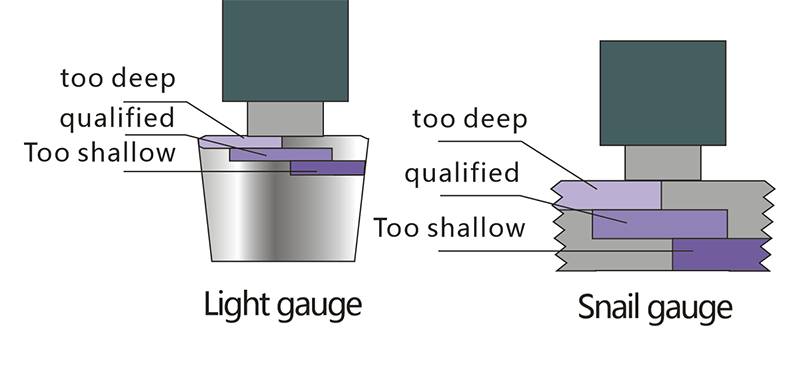

In actual production, many manufacturers rely solely on thread ring gauges to inspect NPT threads. However, these gauges only check the pitch, not the taper. To achieve a proper seal in tapered pipe threads, both the taper (checked with a plug gauge, or "light gauge") and the pitch (checked with a thread gauge) must be verified and meet specifications. Only when both criteria are satisfied can a truly effective seal be achieved.

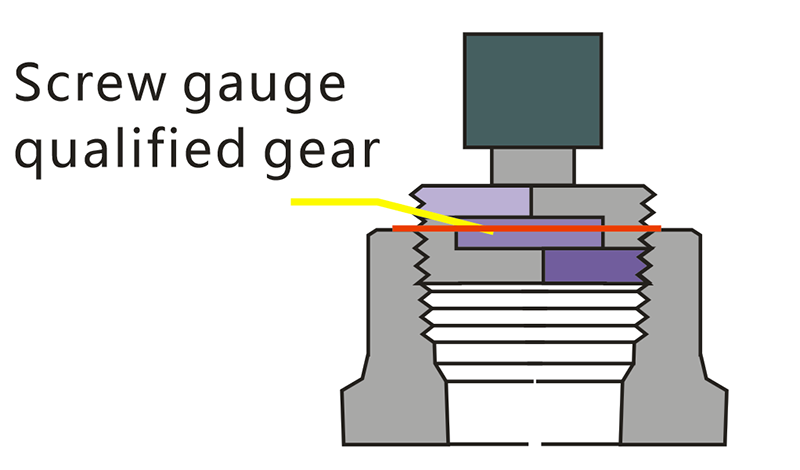

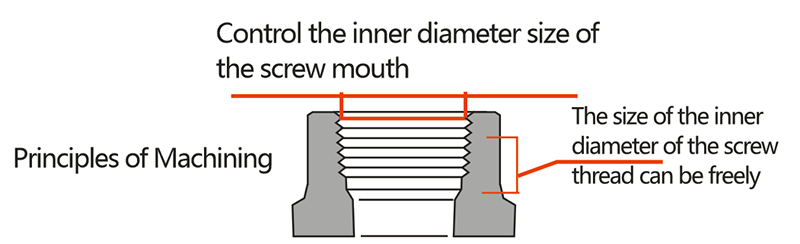

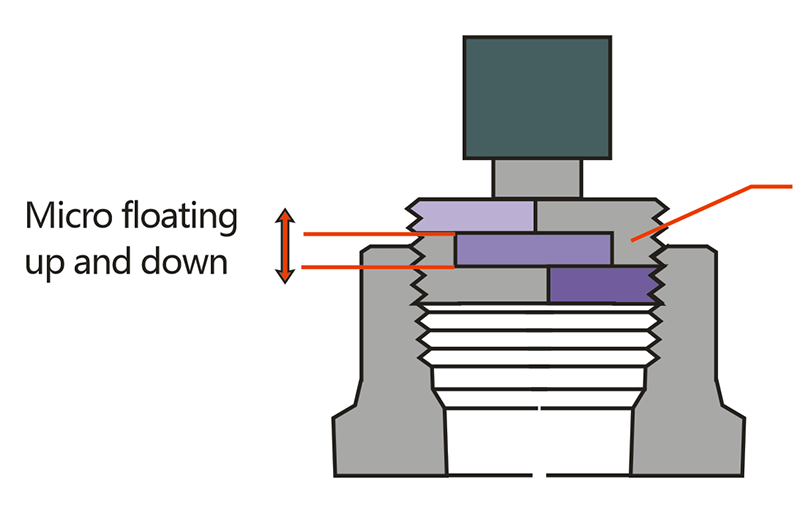

If, during finished valve inspection, all thread gauge results appear perfectly consistent. Every thread tests as a perfect pass with no variation, and this may indicate counterfeit or improper threading. True NPT threads naturally exhibit minor deviations due to acceptable tolerances. Absolute uniformity often signals that only the internal diameter has been controlled during machining, while other critical parameters have been neglected. This shortcut allows for faster machining and eliminates the need for concerns such as tool wear or high-precision programming.

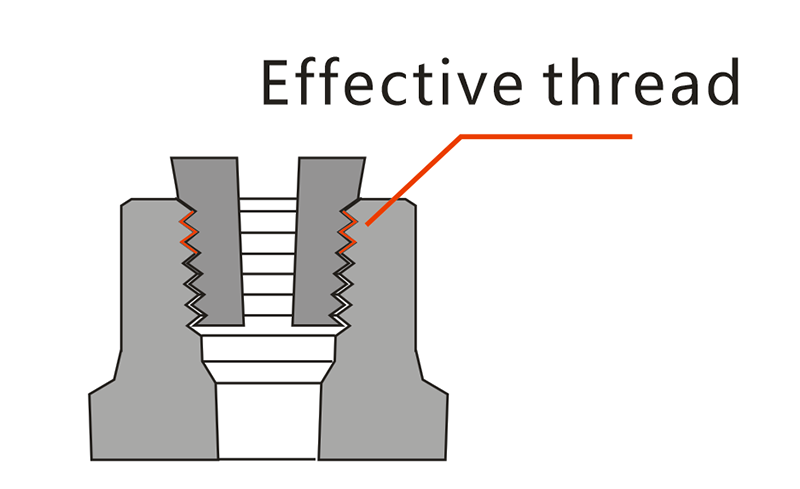

In genuine machining processes, acceptable thread gauge results will still show some variation within the tolerance band. Counterfeit threads, however, may only seal at a few teeth near the thread entrance, falling short of the full sealing standard required for tapered pipe threads.

This becomes particularly risky for high-pressure applications, such as 1500–2500 LB-rated ball valves with threaded connections. Under high-pressure hydrostatic testing, improperly formed threads can deform, causing the seal to fail. Similarly, during fire tests, leakage from drain valves or grease injection ports is often traced back to substandard thread machining.

To ensure the integrity of NPT threads, a two-step inspection process must be followed:

Plug Gauge (Light Gauge) Test: This is used to verify the internal taper of the thread. The gauge should enter smoothly within the acceptable zone and should not wiggle or shift laterally. Any noticeable play indicates that the taper is out of specification and the machining is faulty.

Thread Gauge Test: After passing the taper test, the pitch should be verified using the standard thread ring gauge.

Only when both tests are passed can the NPT thread be considered compliant and properly sealed. This dual-inspection process represents the industry standard for ensuring the quality and reliability of NPT threaded connections.