In China, many manufacturers struggle with achieving a perfect seal on swing check valves under 0.6MPa air pressure, especially during nitrogen gas seal testing. The challenge lies primarily in the manufacturing process, where traditional methods are still widely used to grind the valve seat and disc.

Traditional Method 1: Sanding Wheel Grinding

One common technique involves finely machining the valve seat ring and then polishing the sealing surface using a high-speed rotating abrasive wheel.

Traditional Method 2: Manual Lapping

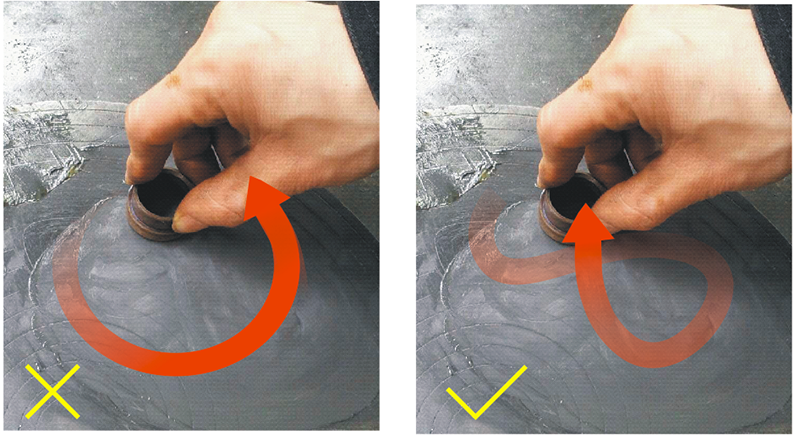

After initial grinding, the valve seat is often further lapped on a cast iron plate. However, many operators use the incorrect circular lapping motion instead of the more effective figure-eight motion.

The figure-eight technique distributes force more evenly and produces a flatter, harder sealing surface between the valve seat and disc.

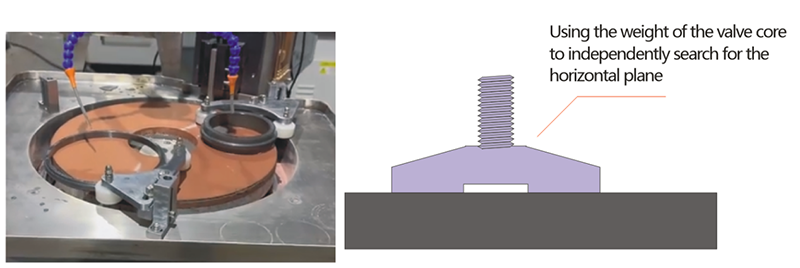

The Importance of Mechanical Lapping

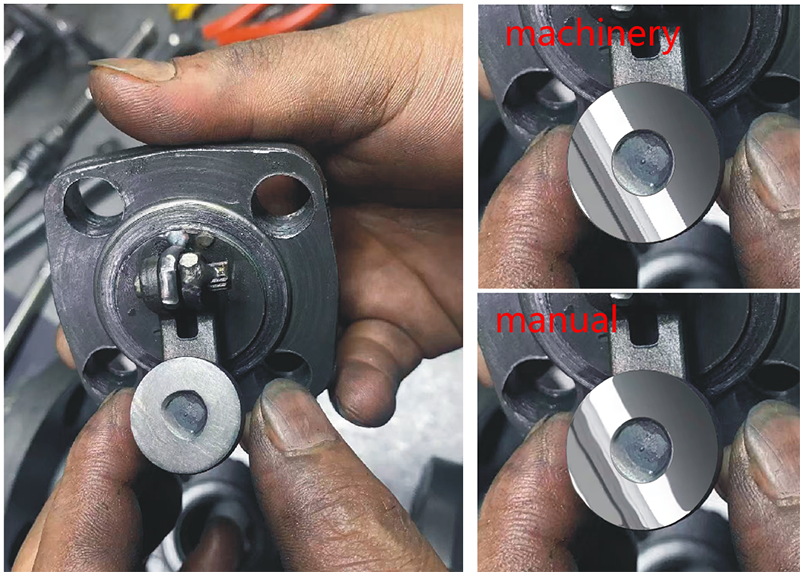

To achieve a truly effective seal at low air pressures, mechanical lapping is essential. There is a fundamental difference between manual and mechanical lapping:

Manual Lapping: Often results in poor surface roughness and flatness. Even if the surface appears shiny, inconsistencies become obvious under light reflection—distortions reveal uneven surfaces due to inconsistent hand pressure, typically resulting in slightly convex surfaces.

Mechanical Lapping: Produces a uniformly flat, highly polished surface. The reflection of light is straight and clean, indicating high surface precision and tight tolerances.

The Root of the Problem

A proper seal only occurs when both the valve disc and seat exhibit excellent flatness and surface finish. Unfortunately, many factories rely on fluid pressure to force the sealing surfaces together. This method may work under high pressure but fails at low pressures like 0.6MPa, where the gas leakage rate is too low to generate enough sealing force. This reflects a fundamental flaw in their initial sealing theory.

Conclusion

To achieve a perfect seal under low-pressure air tests, especially with inert gases like nitrogen, factories must abandon outdated manual grinding techniques and adopt precision mechanical lapping. Only with perfectly flat and smooth contact surfaces can reliable sealing be consistently achieved.