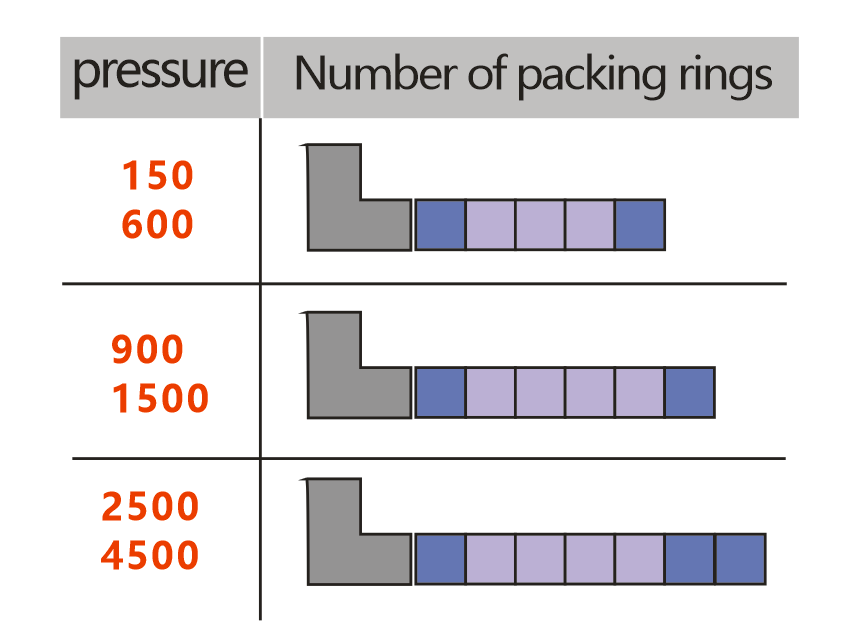

The sealing performance of packing is not simply improved by increasing the number of rings. More rings do not necessarily lead to better sealing.

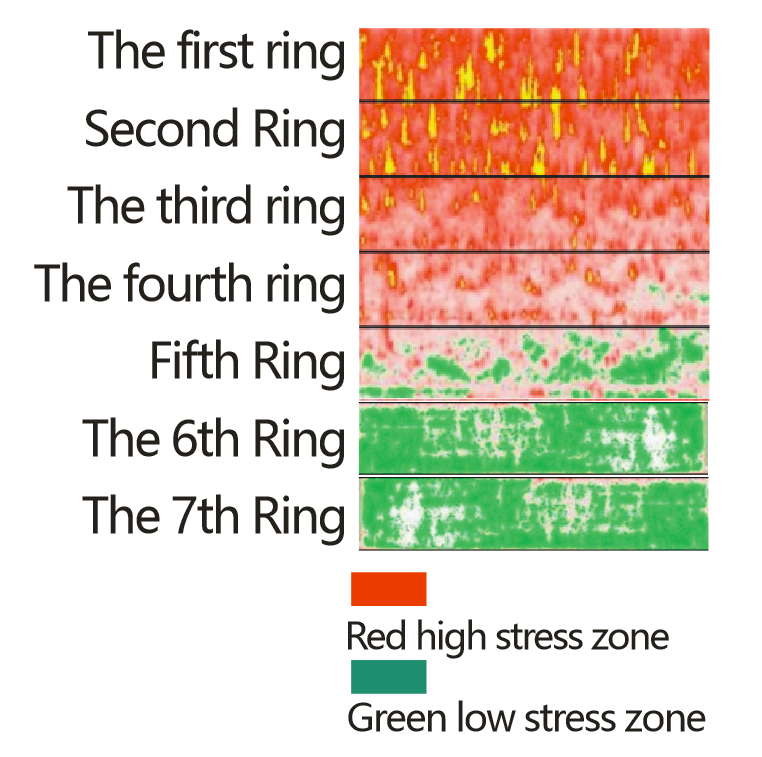

The most straightforward method to assess this is through stress testing using stress-sensitive film, which allows us to measure the stress distribution after the entire packing set is installed.

Our tests show that a configuration of five rings delivers the optimal lateral force and the best sealing performance.

Therefore, it is essential to determine the appropriate number of packing rings and installation method based on the specific pressure requirements. In addition, pre-calculated process parameters such as the jack bolt torque must be considered.

In practice, we recommend multiple pre-compression steps for packings with an outer diameter greater than 40 mm, especially for pressure ratings of 2500 LB and above, to ensure stable long-term performance.

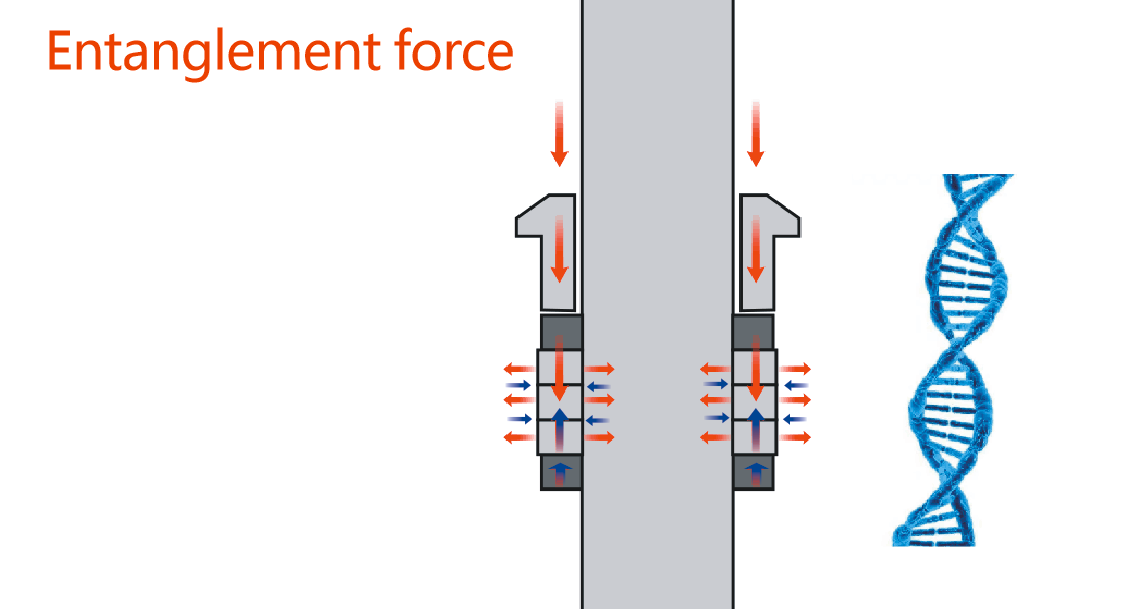

Packing sealing typically manifests in two mechanical forms:

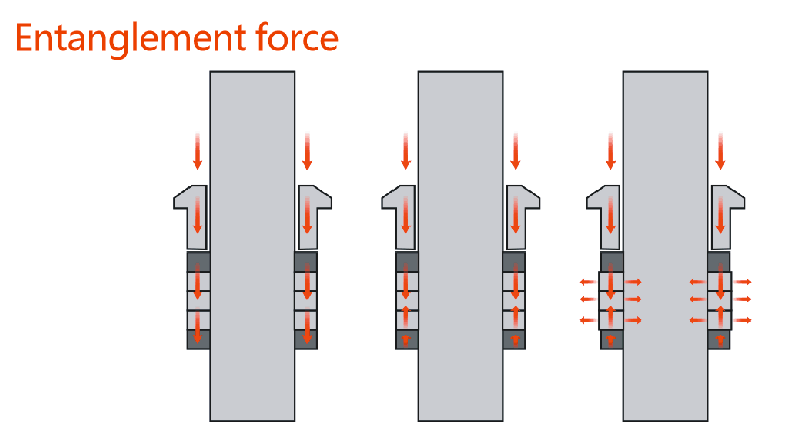

Blocking type

Interlocking (entangled) type

The blocking type tends to show increasing leakage over time as the number of usage cycles rises. The jack bolts tend to loosen, and the system cannot withstand vibrations caused by thermal cycling. Over time, looseness at the bottom of the packing set redistributes density unevenly, compromising sealing effectiveness.

In contrast, the interlocking type can achieve long-term sealing stability. Its leakage remains nearly constant regardless of use cycles. This is because a well-designed number of packing rings induces two interlocking mechanical forces that work together to maintain a persistent seal.

The 5–6 ring configuration is specifically designed to create two interlocking mechanical forces. When the jack bolt applies axial force, it is transmitted to the bottom of the packing set, creating a reactive force. The interaction between these two opposing forces generates lateral sealing pressure, resulting in a highly durable and stable seal.

This mutual force entanglement makes the packing behave like a "living" system. It embodies the balance of dualities—positive and negative, hard and soft, one and zero—much like the double helix structure of DNA, where two strands work in tandem.

Only through proper experimentation and theoretical understanding can we truly grasp the essence of dynamic sealing and develop safer, more reliable low-fugitive-emission valves.