This case focuses on a failure observed in a 4-inch metal-seated floating ball valve used in a thermal power plant handling 380°C steam. The issue involved seizure due to thermal expansion and packing leakage.

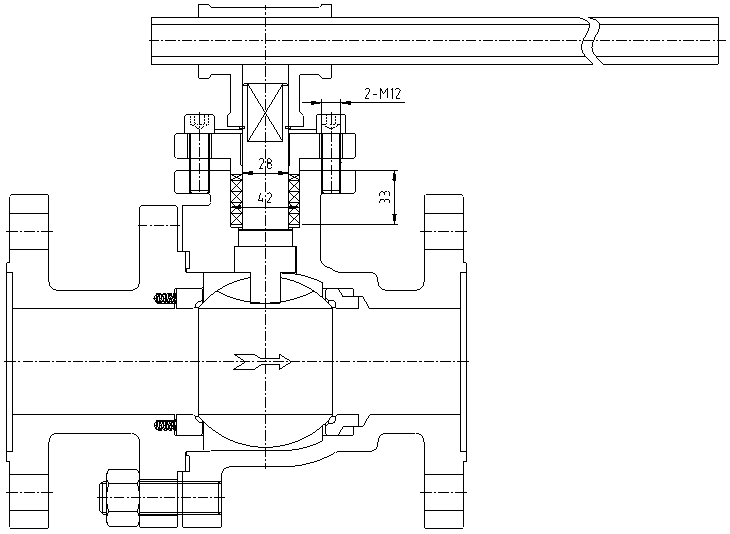

Valve Type: Metal-seated floating ball valve with unidirectional sealing using a spring-loaded seat and graphite packing with a gland.

Factory Testing: Passed hydro and air pressure tests with a low operating torque of 67 Nm under room-temperature water pressure.

On-site Conditions:

Medium: 380°C superheated steam

Operation Frequency: 5–6 cycles per day (low frequency)

Problem: Valve seizure and packing leakage

At the factory, the test medium contains traces of oil, providing lubricity during open/close cycles. However, under high-temperature steam, all oil and grease are burned or flushed away, resulting in pure dry friction between the hard surfaces of the ball and seat. This causes:

Surface galling and initial scratches

Increased torque over time

Inadequate material selection for high-temperature dry friction not considered in design

Many engineers overlook the sealing principle of graphite in hard-seated ball valves:

Floating ball valves seal via the front and rear faces of the graphite ring.

Trunnion-mounted valves seal by compression between the inner and outer diameters.

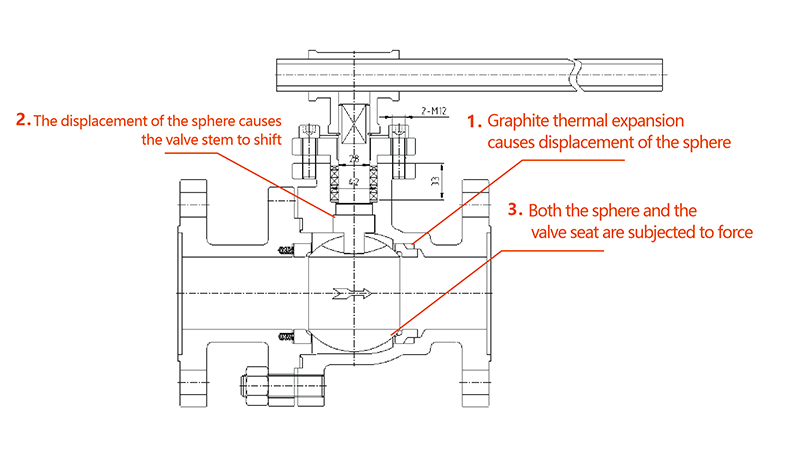

In this case, the graphite ring behind the seat was too thick (8–10 mm). When exposed to high temperatures, the graphite expands significantly, causing:

Seat displacement and misalignment

Stem offset, leading to uneven loading and excessive friction

Difficult valve operation (jerky movement during opening/closing)

The combined effects of dry friction and thermal expansion lead to:

Galling between the ball and seat

Increased operating torque

Stem misalignment, which damages the graphite ID, eventually causing external leakage

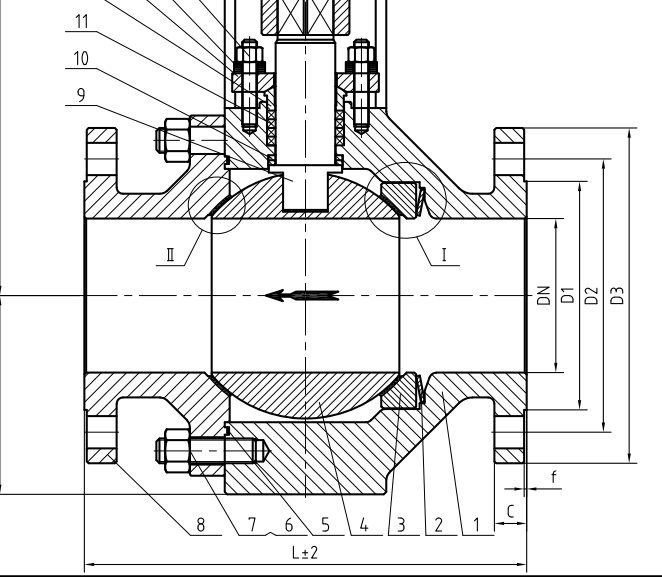

Reduce the graphite ring thickness from 8–10 mm to 2 mm

Use a face-sealing design, which:

Maintains seat sealing integrity

Minimizes thermal expansion

Prevents ball misalignment

Replace the separate seat-graphite design with a monolithic seat, eliminating graphite altogether and removing thermal expansion risks (as shown in the reference design)

This case illustrates the importance of correct valve selection based on operating conditions and media. A lack of understanding of the sealing mechanism or experience in high-temperature service can lead to system-wide failures and costly shutdowns.