In industrial production, sealing technology is one of the key links to ensure the normal operation of equipment and the safety of production. As an important sealing material, high-temperature packing plays an indispensable role in many industrial fields with its excellent performance. This article will deeply explore the types, characteristics, production processes, and application ranges of high-temperature packing, providing you with a comprehensive understanding of this guardian of industrial sealing.

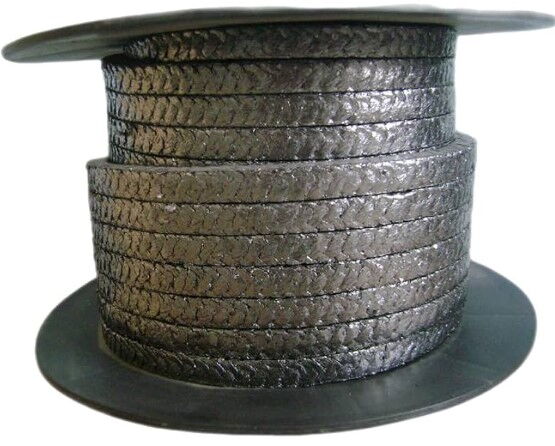

High-temperature packing, also known as high-temperature packing sealing filler, is a material used to achieve sealing functions. It is usually woven from relatively soft linear materials into strips with a square cross-section, which are filled into the sealing cavity to achieve sealing effects. This kind of packing mainly uses graphite and various fibers as the main materials, and according to different usage requirements, it is reinforced with carbon fiber, copper wire, SS 304, SS 316L, Inconel alloy wire, and other materials. High-temperature packing can adapt to both relatively low and relatively high-temperature environments, occupying an important position in the field of sealing materials.

According to its mineral composition, high-temperature packing can be divided into two categories: glassy fibers and polycrystalline fibers. The production of glassy fibers adopts the process of "resistance melting and blowing (or spinning) to form fibers, followed by dry-needle punching to make blankets." These fibers have good flexibility and certain high-temperature resistance, suitable for sealing requirements within a medium temperature range.

Polycrystalline fibers, on the other hand, are produced through the "colloidal method of blowing (or spinning) fibers, followed by high-temperature heat treatment." Polycrystalline fibers have higher high-temperature resistance and better mechanical strength, and can maintain stable sealing performance in more severe high-temperature environments.

With the development of technologies such as wet vacuum molding, fiber weaving, fiber spraying, and the production of amorphous fiber materials, the production process and equipment for high-temperature packing and its secondary products have become increasingly perfect. The progress of these technologies has not only improved the production efficiency and quality of high-temperature packing but also formed a complete series of products, further expanding its application range. Today, the application range of high-temperature packing has expanded from environments below 1200°C to 1200–1600°C high-temperature industrial furnaces, heating devices, and high-temperature pipelines, becoming an effective energy-saving material in these application fields.

After understanding the classification of high-temperature packing, we will now explore several common types of high-temperature packing, their characteristics, and their applications. These packing types play important roles in different industrial scenarios due to their unique materials and manufacturing processes.

Ceramic fiber packing is a kind of packing with strong high-temperature resistance, withstanding temperatures up to 1200°C. It is woven from ceramic fiber yarns, without any impregnating agents, and does not require additional treatment. During application, ceramic fiber packing does not shrink or expand, and its cross-section can be made square as required. This packing has excellent abrasion resistance and high-temperature resistance, and its mechanical strength is further enhanced through metallic wire reinforcement. In addition, ceramic fiber cloth, tape, and felt products also have insulation and heat-preservation advantages, making them perform excellently in high-temperature insulation sealing applications.

Ceramic fiber packing is widely used in power plants, steel mills, and smelting industries, mainly for high-temperature insulation and sealing parts under 1200°C. The commonly used specifications are 4×4–50×50 mm, which can meet the sealing requirements of different equipment. In these industries, ceramic fiber packing provides reliable sealing protection for the stable operation of high-temperature equipment, effectively preventing the leakage of high-temperature gas or liquid and ensuring the safety and efficiency of production.

The temperature range of graphite packing is wide, and it can be used in environments from -300°C to +600°C. It is suitable for sealing granular fluids and their media, steam, organic solvents, acids, alkalis, and various other media. It is widely used in machinery, pumps, valves, pipelines, and containers for fluid transportation equipment and devices.

Graphite packing has many excellent characteristics. Firstly, it has good lubricity, which can reduce friction with valve stems and other parts, thereby reducing wear. Secondly, graphite packing has high-temperature resistance, high-pressure resistance, and wear resistance, among which its high strength is the most outstanding. These features make graphite packing particularly suitable for dynamic sealing parts containing solid particle media. In terms of technical parameters, the pressure of graphite packing can reach 26 MPa, and its chemical resistance is in the pH range of 2–7, meeting the sealing requirements of most industrial environments.

The temperature range of carbon fiber packing is -200°C to +350°C. It is suitable for sealing corrosive liquids such as acids and alkalis, organic solvents, and other media. It is widely used in the sealing of flanges, valves, reactors, and pumps in the petroleum, chemical, chemical fiber, coal mining, power generation, and metallurgical industries.

Carbon fiber packing has excellent thermal conductivity, wear resistance, chemical stability, high mechanical strength, small starting torque, and will not cause damage to pump shafts. These characteristics give carbon fiber packing a long service life, making it an ideal material for various dynamic and static seals. Its technical parameters are: temperature range -200°C to +350°C, pressure up to 30 MPa, and chemical resistance in the pH range of 1–14, which can adapt to a wide range of chemical environments and provide reliable sealing protection for industrial equipment.

The temperature range of aramid fiber packing is -200°C to 280°C. It is woven from aramid fibers after being impregnated with PTFE emulsion and lubricant treatment, with good chemical resistance, high resilience, and low cold flow. Aramid fiber packing also has excellent high-speed and high-modulus properties and is known as artificial metal wire. Compared with other types of packing, it can resist particle crystallization media and higher temperatures and can be used alone or in combination with other packings.

Aramid fiber packing is an excellent asbestos replacement product for pump systems and is widely used in chemical, petroleum, pharmaceutical, food, sugar, pulp, paper, and power industries. It is suitable for abrasive media containing solid particles and is recommended for sealing superheated steam, solvents, liquefied gas, syrup, and other easily worn fluids. The product specifications of aramid fiber packing are 3×3 mm to 50×50 mm, and special specifications or non-standard products can be customized according to customer requirements to meet the sealing needs of different equipment and processes.

Taking graphite packing as an example, its installation process requires special attention. After the graphite packing is loaded into the stuffing box, axial pressure is applied through the tightening bolts on the gland. Since the packing has a certain degree of plasticity, after being subjected to axial pressure, radial pressure and micro-deformation will be generated, making the inner hole closely fit with the valve stem. However, this fit is not uniform along the length. The upper and lower parts of the packing in the packing area are unevenly subjected to medium pressure, resulting in inconsistent plastic deformation between the two parts, which can easily lead to local over-sealing or under-sealing between the packing and valve stem.

At the same time, the radial compressive force near the gland is the largest, which brings the greatest friction between the packing and valve stem. At this position, the valve stem and packing are prone to wear. At high temperatures, the higher the temperature, the greater the expansion of graphite packing, and the greater the friction. Insufficient heat dissipation caused by high temperatures will accelerate the wear rate of the valve stem and packing, which is also one of the main reasons for external leakage of high-temperature valve packing. Therefore, under high-temperature working conditions, selecting a suitable packing structure is crucial.

To address the issue of external leakage of valve packing under high-temperature conditions, a compensatory valve packing structure has been proposed. This structure is specially designed for different conditions of high-temperature low-pressure and high-temperature high-pressure, effectively solving the problem of valve leakage under high-temperature conditions.

The high-temperature low-pressure packing structure combines a specially designed compensatory ring spring with composite graphite packing. Since the working pressure is not high, the packing spacer is eliminated. A specially designed compensatory ring spring is added at the bottom of the stuffing box, and a certain pre-tightening force must be applied through tightening bolts during installation. Even if frictional wear occurs between the graphite packing and the valve stem, the ring spring can make instantaneous compensatory adjustments, ensuring that the valve does not leak. This design cleverly utilizes the elastic compensation function of the spring, effectively solving the sealing problem of traditional graphite packing under high-temperature low-pressure conditions, improving valve reliability and service life.

The high-temperature high-pressure packing structure is an advanced packing system that adopts an external dual-compensation structure composed of disc springs and ring springs. This structure avoids the disadvantage of spring failure caused by excessively high temperature. Especially under extreme high-temperature and high-pressure conditions, even if one compensation point fails, the other set remains effective; the two do not interfere with each other, compensating independently while working together on the packing. The closed nature of the disc spring makes it suitable for harsh outdoor conditions, and the external structure of the two compensation points facilitates replacement without disassembling the entire stuffing box, greatly improving operational efficiency and convenience.

Through long-term user tracking and practical application verification, this high-temperature high-pressure packing structure has shown significant effects in preventing external leakage of valve stem seals under high-temperature and high-pressure conditions, with a long service life. It provides a reliable sealing solution for high-temperature and high-pressure valves, effectively ensuring the safe operation of high-temperature and high-pressure equipment in industrial production, reducing production accidents and economic losses caused by sealing failure.

As an important industrial sealing material, high-temperature packing plays a vital role in high-temperature industrial furnaces, heating devices, and high-temperature pipelines. Through continuous technological innovation and product upgrading, the performance of high-temperature packing has been significantly improved, and its application range has been continuously expanded. From traditional ceramic fiber packing, graphite packing, and carbon fiber packing to the new aramid fiber packing, as well as compensatory valve packing structures developed for high-temperature conditions, high-temperature packing provides reliable protection for the safe and efficient operation of industrial production.