Magpie Hydrogenation Packing Technical Requirements

This specification stipulates the technical requirements, testing methods, and inspection rules for flexible graphite packing rings (hereinafter referred to as packing rings) used in high-pressure hydrogenation, hydrogen-containing, and H2S-resistant valves, and notes the relevant certification standards that manufacturers need to provide.

GB/T 1801 Product Geometric Technical Specifications (GPS) - Limits and Fits - Selection of Tolerance Zones and Fits

GB/T 1804 General Tolerances - Tolerances for Linear Dimensions without Specified Tolerances

GB 2828 Sampling Procedures for Inspection by Attributes - Part 1: Sampling Schemes Indexed by Acceptable Quality Level (AQL) for Lot-by-lot Inspection

GB 2829 Sampling Procedures for Inspection by Attributes - Part 2: Sampling Schemes Indexed by Limiting Quality (LQ) for Periodic Inspection

JB/T 6623 Method for Determination of Sulfur Content in Flexible Graphite Sheet

JB/T 6622 Method for Determination of Chlorine Content in Flexible Graphite Sheet

JB/T 6370 Test Methods for Physical and Mechanical Properties of Flexible Graphite Packing Rings

ZB J22 010 Test Method for Tensile Strength of Flexible Graphite Sheet

ZBJ 22013 Test Method for Ash Content of Flexible Graphite Sheet

JB/T 6617 Technical Conditions for Flexible Graphite Packing Rings for Valves

3.1 Certification Requirements

Packing manufacturers shall provide certification in compliance with API 622 or ISO 15848-1.

3.2 Materials

The performance of the flexible graphite tape (sheet) used for packing rings shall meet the requirements specified in Table 1.

|

Performance |

Unit |

Indicator |

|

Tensile Strength |

MPa |

≥3.5 |

|

Ash Content |

% |

≤5.0 |

|

Sulfur Content |

ppm |

≤200 |

|

Chlorine Content |

ppm |

≤50 |

|

Fluorine Content |

ppm |

≤100 |

Table 1

The pure carbon content of flexible graphite packing shall not be less than 98%. The packing shall not contain any binders, lubricants, or other additives.

For metal-wrapped flexible graphite packing, INCONEL metal wire or other corrosion-resistant alloy wire materials shall be used. The service life of the packing shall be no less than 5 years, and it shall be able to withstand long-term exposure to "hydrogen, oil vapor, hydrocarbons + hydrogen + hydrogen sulfide" under conditions of 450°C without failure, with the valve stem seal leakage not exceeding the Grade B provisions of ISO 15848-2.

3.3 Quality

3.3.1 The surface of the packing ring shall not have obvious scratches, burrs, or other defects. The packing ring shall contain a corrosion inhibitor.

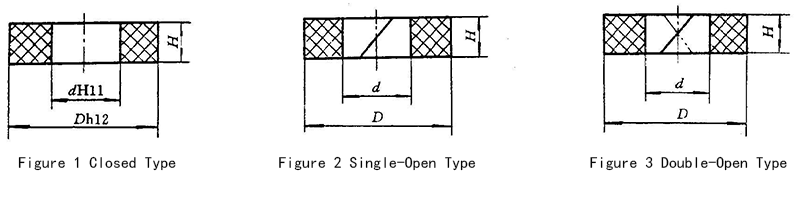

3.3.2 The packing ring can be divided into three forms according to requirements: closed type, single-open type, and double-open type (see Figure 1, Figure 2, and Figure 3). The open-type packing ring is made by a 45° (or 60° if required) cut, which shall be flat without any unraveling.

3.4 The form and size of the packing ring can be selected according to user requirements. The dimensional tolerance of the closed-type packing ring is as shown in Figure 1, and the tolerance grade for dimensions not specified shall be in accordance with the m (medium) level specified in GB/T 1804.

3.5 The physical and mechanical performance indicators of the packing ring shall meet the requirements specified in Table 2.

|

Performance |

Unit |

Indicator |

|||

|

Single Flexible Graphite Type |

Metal Composite Type |

Resin Composite Type |

|||

|

Density |

g/cm3 |

1.4-1.7 (pre-formed) |

≥1.7 |

≥1.5 |

|

|

Compression Rate |

% |

10-25 |

7-20 |

10-25 |

|

|

Recovery Rate |

% |

≥35 |

≥35 |

≥35 |

|

|

Temperature Resistance Loss 1) |

250°C |

% |

≤0.3 |

— |

≤1.0 |

|

450°C |

% |

≤0.8 |

≤0.6 |

— |

|

|

600°C |

% |

≤8.0 |

≤6.0 |

— |

|

|

Friction Coefficient |

≤0.14 |

≤0.14 |

≤0.14 |

||

Table 2

Note: 1) When the melting point of the metal is lower than the test temperature, the test at that temperature is not recommended; for resin composite flexible graphite packing rings, the test temperature may be determined according to actual requirements depending on the type and proportion of the added resin.

4.1 The appearance quality of the packing ring shall be inspected visually.

4.2 Measurement of Packing Ring Dimensions

4.2.1 The dimensions of the packing ring shall be measured with a vernier caliper with an accuracy of 0.02 mm, accurate to 0.1 mm.

4.2.2 The inner and outer diameters of the packing ring shall be the arithmetic mean of the measurements taken at three equally spaced points along the circumference.

4.2.3 The height of the packing ring shall be the arithmetic mean of the measurements taken at three evenly spaced points along the circumference.

4.3 The density, compression rate, recovery rate, and temperature resistance loss of the packing ring shall be tested in accordance with JB/T 6370.

4.4 The tensile strength of the flexible graphite tape (sheet) used for the packing ring shall be tested in accordance with ZBJ 22010.

4.5 The ash content of the flexible graphite tape (sheet) used for the packing ring shall be determined in accordance with ZBJ 22013.

4.6 The sulfur content of the flexible graphite tape (sheet) used for the packing ring shall be determined in accordance with JB/T 6623, and shall not exceed 50 ppm.

4.7 The chlorine content of the flexible graphite tape (sheet) used for the packing ring shall be determined in accordance with JB/T 6622.

5.1 The packing ring must be inspected and approved by the quality inspection department of the manufacturing plant before it can be released from the factory.

5.2 Product inspection is divided into factory inspection and type inspection.

5.3 The sampling method for the packing ring is random sampling from the warehouse.

5.4 Factory Inspection

5.4.1 The items for factory inspection are those specified in Articles 3.2 to 3.3.

5.4.2 For packing rings of the same specification, each batch produced per shift or each batch ordered is considered as one batch. Sampling inspection shall be carried out in accordance with the one-time sampling plan of GB 2828. The general inspection level IL is II, and the acceptable quality level AQL is 10. Appearance quality shall be inspected in full.

5.5 Type Inspection

5.5.1 Type inspection shall be carried out under any of the following circumstances:

a. Significant changes in product structure, materials, or processes;

b. Continuous production for one year;

c. Production suspension for more than six months;

d. Significant differences between factory inspection results and the last type inspection;

e. Requirements from higher-level quality supervision authorities for type inspection.

5.5.2 The items for type inspection shall be in accordance with Articles 3.1 to 3.4.

5.5.3 The sampling procedure and judgment rules shall be implemented in accordance with GB 2829. A one-time sampling plan shall be adopted, with an RQL value of 30 and a judgment level of II.

6.1 Marking

The packing box of the packing ring shall be marked with the following:

a. Product name;

b. Manufacturer's name;

c. Product trademark;

d. Product model or marking;

e. Gross weight, net weight;

f. Manufacturing date or production batch number.

6.2 Packaging

6.2.1 The packaging of the packing ring shall ensure that it is not damaged or lost during transportation and storage.

6.2.2 A packing list shall be included in the packing box, which shall indicate the following:

a. Product name;

b. Product trademark;

c. Manufacturer's name;

d. Quantity of products;

e. Product specifications;

f. Manufacturing date.

6.2.3 A product qualification certificate shall be included in the packing box, which shall indicate the following:

a. Batch number;

b. Standard number;

c. Inspector's name or code.

6.3 Transportation and Storage

6.3.1 The packing ring must be protected from rain and moisture during transportation.

6.3.2 The packing ring shall be stored in a clean and dry warehouse.