Product Performance Test Report

Report Number: 17QX909

No: 20180129002

|

Product Name |

Flexible Graphite Packing Ring |

Sample Numbers |

18010633-2 (Ordinary Graphite) 18010632-4 (Nuclear Grade Graphite) 18010994-6 (High-Temperature Resistant Graphite)

|

|

Product Batch Numbers |

18010632, 18010633, 18010994 |

Quantity |

3 sets (2 pieces per set) |

|

Manufacturer |

Zhejiang Magpie Sealing Co., Ltd |

Product Specification |

φ30*φ46*8 |

|

Date of Submission for Inspection |

2017-01-11 |

Inspection Dates |

From 2017-01-11 to 2017-01-12 From 2017-01-15 to 2017-01-19 From 2018-01-22 to 2018-01-26 |

|

Test Item |

Under the same temperature and humidity conditions, corrosion of metal materials when equipped with different grades of graphite packing rings |

||

|

Test Basis |

JB/T 9143-1999 Method for Corrosion Test of Anti-corrosive Asbestos Packing |

||

|

Test Equipment |

Equipment Name: High and Low Temperature Chamber |

||

|

Note |

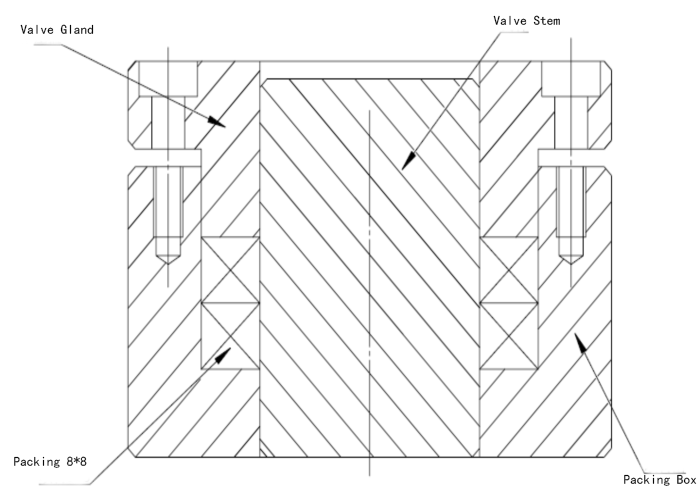

Valve Stem Material: 45# Steel Graphite materials: 9104 is ordinary graphite; 9204 is nuclear-grade graphite; 9404 is high-temperature resistant graphite. |

||

|

Item |

9104 Ordinary Graphite |

9204 Nuclear-Grade Graphite |

9404 High-Temperature Resistant Graphite |

|

Total Sulfur Content (mg/kg) |

≤1200 |

<200 |

<200 |

|

Total Halogens Content (mg/kg) |

-- |

<200 |

<200 |

|

Free Chlorine Content (mg/kg) |

≤80 |

<30 |

<50 |

|

Free Fluorine Content (mg/kg) |

-- |

≤50 |

<50 |

|

Thermal Loss (450℃) (%) |

≤1.0 |

≤0.5 |

<0.3 |

|

Thermal Loss (600℃) (%) |

≤20 |

≤20 |

<3 |

|

Thermal Loss (700℃) (%) |

-- |

-- |

<12 |

|

Tensile Strength (MPa) |

≥4 |

≥4.5 |

≥4.5 |

1. Appearance of No. 18010633-2 (Ordinary Graphite)

2. Appearance of No. 18010632-4 (Grade 9204 Nuclear Graphite)

3. Appearance of No.: 18010994-6 (Grade 9404 High-temperature Resistant Graphite)

|

No. |

Gasket No. |

Size Specifications |

Material |

Test Parameters |

Remarks |

||||||||||

|

Temperature (℃) |

Humidity (%) |

Time (h) |

Axial Clamping Force (MPa) |

||||||||||||

|

1 |

18010633-2 |

φ30*φ46*8 |

9104 |

55±2 |

95±3 |

5*24 |

1.5 |

Pitting observed at packing contact area |

|||||||

|

2 |

18010632-4 |

φ30*φ46*8 |

9204 |

55±2 |

95±3 |

5*24 |

1.5 |

Maintained original brightness |

|||||||

|

3 |

18010994-6 |

φ30*φ46*8 |

9404 |

55±2 |

95±3 |

5*24 |

1.5 |

Less than 1/3 area of packing contact lost luster |

|||||||

|

Assessment Standard |

|||||||||||||||

|

Grade 1 |

Maintained original brightness |

Refer to the requirements in JB/T 9143-1999 Corrosion Test Method for Anti-corrosive Asbestos Packing |

|||||||||||||

|

Grade 2 |

Less than 1/3 area of packing contact lost luster |

||||||||||||||

|

Grade 3 |

Pitting observed at packing contact area |

||||||||||||||

|

Grade 4 |

Severe corrosion at packing contact area |

||||||||||||||

|

Results |

□ Qualified □Unqualified √Other |

Signature |

|

||||||||||||

|

Notes |

Based on the comparison of the valve stem before and after testing: 18010632-4 (Grade 9204 Nuclear Graphite) is Grade 1. 18010994-6 (Grade 9404 High-temperature Resistant Graphite) is Grade 2. 18010633-2 (Grade 9104 Ordinary Graphite) is Grade 3. |

||||||||||||||

|

Tested by |

|

Reviewed by |

|

Approved by |

|

||||||||||

|

Date |

|

Date |

|

Date |

|||||||||||