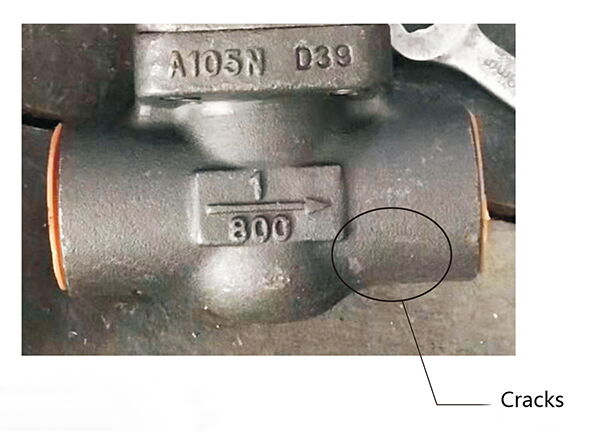

Due to the high daily production volume of forged steel valve bodies, there is a certain proportion of surface cracks (shallow and deep), which are also difficult to completely resolve through the forging process.

For A105 class valve bodies, fine cracks on the surface of the round steel due to material cutting are the causes of shallow surface cracks.

Chromium steels, due to their high chromium content, produce cracks that are relatively deep. Actual statistics show that the proportion of cracks can be as high as 5%.

Using Pt plating for color detection is impractical in terms of efficiency and cost compared to previous batch processes.

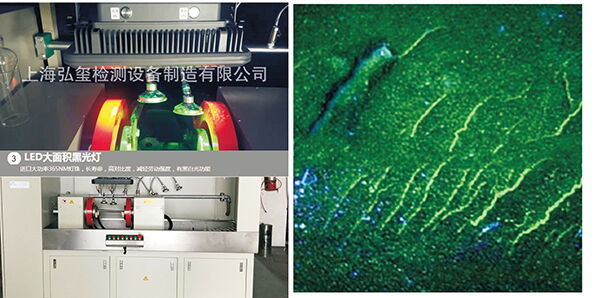

For mass production of rough castings, a water-based magnetic particle flaw detector can be used.

It is very convenient and intuitive to use, and it can detect 99.9% of the cracks with very low operating costs. However, it is ineffective for non-magnetic materials like stainless steel (although cracks in stainless steel valve bodies are rare and almost non-existent, except for high nickel content duplex steels).

This can save unnecessary machining costs and improve the yield rate to offset the initial inspection costs.

After the initial screening of the rough castings, there may still be individual castings with cracks. At this point, these can be detected by direct visual inspection after the semi-finished products have undergone phosphating during machining. This ensures that defective parts do not enter the assembly stage.

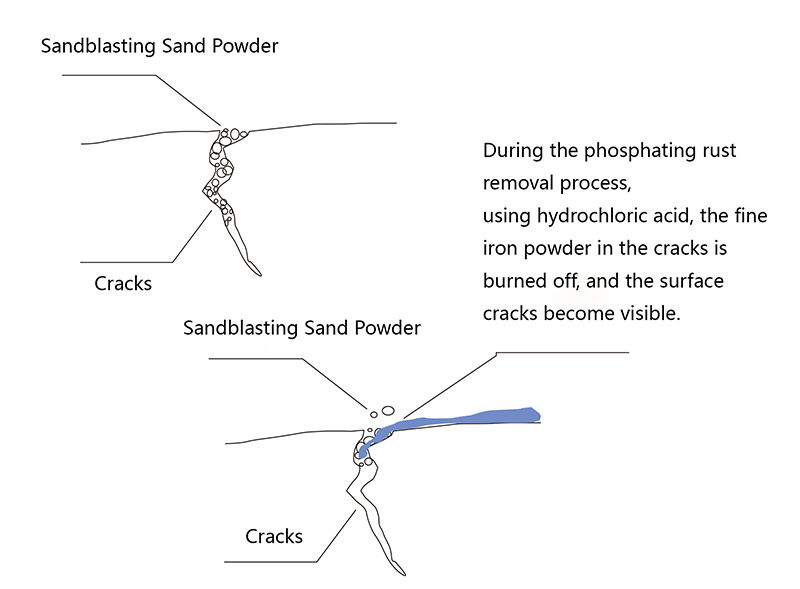

It's difficult to detect surface cracks without phosphating and blackening. This is because after sandblasting, the sand particles fill the cracks. It's hard to spot them with the naked eye, and the sensitivity of the Pt plating inspection is also low. It's challenging to remove UM-grade fine sand particles during the pre-PT cleaning process.