In the field of automated control valves, fluid control engineers serve as the essential bridge between process requirements and equipment reliability. Their role spans the full spectrum from operating condition analysis to the final implementation of solutions. Success in this position requires not only a solid foundation in fluid control theory, but also the ability to apply specialized knowledge to solve complex engineering problems related to automatic control valves with precision and efficiency.

The professional capabilities of a fluid control engineer are demonstrated through their precise command of the fluid control process from multiple dimensions:

Engineers must deeply understand the interrelationships between key system parameters, including temperature, pressure, flow rate, and media state (gas, liquid, or multiphase flow)—as well as physical properties like viscosity, density, and corrosiveness. This enables them to build accurate, condition-based analytical models.

They are expected to master the mathematical foundations behind critical phenomena such as flashing, cavitation, and pressure drop distribution. For example, under high-pressure-drop and high-temperature scenarios, engineers employ computational fluid dynamics (CFD) simulations to quantify phase transitions—like the generation and collapse of vapor bubbles during flashing—to predict cavitation risks that could damage valve sealing surfaces and flow passages.

Consider the following real-world scenarios:

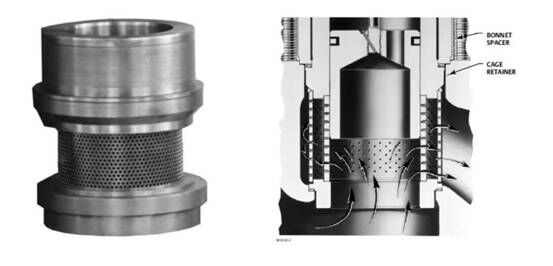

A customer needed to regulate a high-pressure, high-temperature liquid. Upon depressurization, the medium was prone to flashing and subsequent cavitation, posing serious threats to equipment longevity and operational safety. The engineer addressed this by selecting a valve with a multi-stage pressure reduction design, using anti-cavitation materials such as hard alloys, and optimizing the internal flow channel for streamlined flow. These strategies successfully kept cavitation within safe limits, ensuring valve stability under severe conditions.

In systems handling media with solid particles or crystallization tendencies, engineers must balance flow efficiency with anti-clogging performance. By calculating expanded flow channels and optimizing sealing structures (e.g., incorporating resilient seats), engineers tackle the dual challenge of preventing media buildup and resisting abrasion, ensuring uninterrupted operation.

The core value of a fluid control engineer lies in their ability to form a closed-loop capability encompassing: condition analysis – theoretical calculation – technical selection – structural design. By accurately capturing physical changes in media (such as flashing mechanisms) and combining interdisciplinary knowledge in materials science, mechanical design, and fluid mechanics, engineers can achieve maximum cavitation suppression and service life optimization during valve selection and design. This ultimately provides clients with fluid control solutions that are both reliable and cost-effective.

In short, a qualified fluid control engineer is not just an interpreter of technical data, but a guardian of industrial safety and operational efficiency, fortifying the foundation of equipment performance through technical expertise, and connecting customer needs with practical engineering outcomes through informed valve selection.