Magpie Sealing Technology Insights

Flanges and Gaskets – Non-metallic Gasket Forms (Part 2): Base Materials for Non-metallic Gaskets

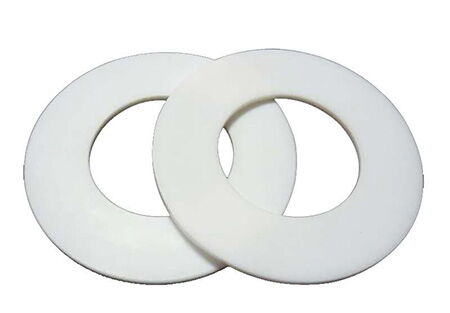

In the broad classification of gaskets, non-metallic gaskets stand out for their diverse forms, thanks to the unique composition of their base materials. These gaskets are engineered to meet the demands of various industrial applications through tailored performance characteristics.

These gaskets are primarily composed of mineral materials such as asbestos, glass fibers, and ceramics. Known for their high-temperature resistance, corrosion resistance, and mechanical strength, they are widely used in harsh industrial environments involving heat and aggressive chemicals.

Rubber-based gaskets utilize both natural rubber (NR) and various synthetic rubbers. Common types include:

Nitrile rubber (NBR): excellent oil resistance

Chloroprene rubber (CR): good weathering and ozone resistance

Styrene-butadiene rubber (SBR): cost-effective and abrasion-resistant

Fluorocarbon rubber (FPM/Viton): high chemical and heat resistance

Silicone rubber (VMQ): outstanding low- and high-temperature flexibility

EPDM rubber: strong resistance to weather, ozone, and chemicals

These gaskets are suitable for a broad range of industrial conditions due to their diverse functional properties.

Made from materials such as virgin PTFE (v-PTFE), expanded PTFE (e-PTFE), and filled PTFE (f-PTFE), these gaskets offer:

- Exceptional chemical resistance

- High thermal stability

- Non-stick properties

They are ideal for clean environments and applications requiring excellent chemical compatibility.

This category includes flexible graphite (also known as expanded graphite), carbon fiber, and graphite fiber gaskets. These materials are valued for:

- High thermal and electrical conductivity

- Excellent wear resistance

They are indispensable in high-temperature, high-pressure, and electrically insulating applications.

These gaskets are composed of elastomer materials (rubber or plastic) reinforced with short fibers. The fibers can be inorganic (such as asbestos or mineral wool) or organic (including carbon or graphite fibers). The fiber reinforcement enhances mechanical strength and abrasion resistance, making them suitable for applications with significant mechanical stress.

Each type of non-metallic gasket brings its own strengths and application scope. Proper selection requires a comprehensive assessment of the working environment, the nature of the medium, and the desired sealing performance.

Seal leaks? Magpie solves them.

If you have questions about sealing technology, follow Magpie Sealing for more insights. Feel free to comment or reach out, and we're here to help! Stay tuned for the next installment on gasket forms. See you next time!