Magpie Sealing Technology Insights

Flanges and Gaskets – Gasket Forms (Part 1): Non-Metallic Gaskets in Flange Connections

In industrial piping systems, the integrity of flange connections is critical to preventing leakage and ensuring safe, stable operations. One of the most essential components in this process is the gasket. This article focuses on the classification and form of non-metallic gaskets, a fundamental sealing element widely used across multiple industries.

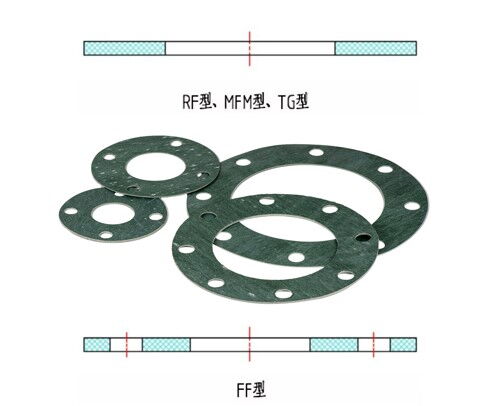

Non-metallic gaskets are sealing components typically made from materials such as graphite, PTFE, rubber, or compressed fiber. They are most commonly manufactured in the flat gasket form and are designed to provide a reliable seal between flange faces.

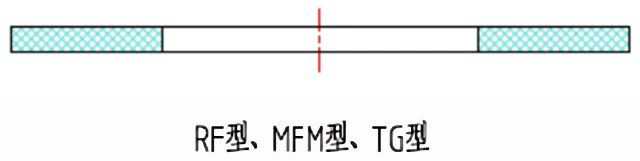

Common Flange Face Types Supported:

RF (Raised Face)

MFM (Male-Female Face)

TG (Tongue and Groove)

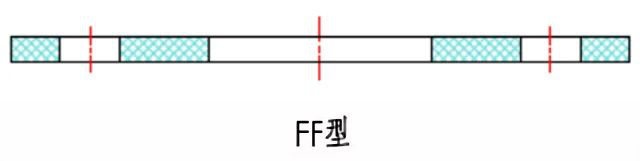

FF (Flat Face)

Non-metallic gaskets offer several performance advantages that make them suitable for a wide range of applications:

✔ Excellent Compressibility and Resilience

They can conform to surface irregularities and flange misalignments, ensuring tight sealing even under varying pressure conditions.

✔ Versatile Application

Their wide compatibility with different flange face types allows them to be used in many industries, including chemical, petrochemical, water treatment, and power generation.

✔ Easy Installation and Replacement

Due to their material flexibility and simple form, non-metallic gaskets can be installed and replaced quickly, reducing system downtime and maintenance costs.

For flat face (FF) flanges, non-metallic gaskets are often designed with bolt holes. This feature enhances alignment and adaptability during assembly, making them ideal for various piping systems with specific connection demands.

Users can choose from a range of gasket thicknesses to meet different sealing requirements, pressure ratings, and operational environments. This flexibility makes it easier to optimize sealing performance for each specific application.

Non-metallic gaskets play an indispensable role in ensuring the reliability and safety of flange connections. With their superior sealing performance, adaptability, and ease of use, they have become an essential component in industrial sealing solutions.

At Magpie Sealing, we specialize in providing solutions to all kinds of sealing challenges. If you have questions about sealing technologies or gasket applications, feel free to follow us, leave a comment, or contact us for expert advice.

Thank you for reading!

Stay tuned for Part 2, where we will continue our exploration of gasket forms and materials.