Magpie Valve Selection: Accurate Matching Ensures Reliable Control

Valve Technology Sharing

Analysis and Solutions for Water Ingress in Control Valve Positioners

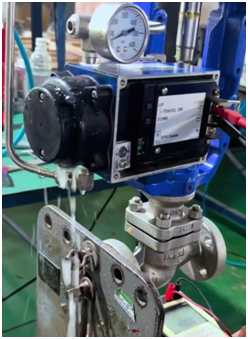

Today, one of our clients sent us a photo of a control valve, as shown above. It has water inside. How did the water get in there? It's likely due to the compressed air. The water has entered the positioner, and there is a lot of water inside, including in the diaphragm. We have now disassembled it to drain the water. The positioner seems to be still usable for now, but I noticed a lot of scale buildup inside. It can still function, but we don't know how long it will last. Our recommendation is to replace the positioner to ensure long-term operation. For control valves, especially smart positioners, it is crucial to prevent water from entering the compressed air. Typically, a water removal device should be installed after the air compressor, such as a refrigerated dryer or an oil-water separator, among other water and oil removal devices. The fact that the on-site equipment has not been started yet and has led to this consequence is a significant loss. Clients and friends, in such situations, it is important to ensure that our water and oil removal devices are in good working condition.

Lack of or Improperly Operating Dehydration and Oil Removal Equipment: The compressed air system may not be equipped with or may be improperly operating essential components like dryers (e.g., refrigerant dryers, oil-water separators, or drain valves on air tanks). This results in the condensation of water vapor in the air, along with impurities such as oil or rust, entering the positioner.

Environmental Factors: High humidity, significant temperature fluctuations, or placing the compressor intake near a humid area (e.g., near cooling towers or puddles on the ground) will increase the moisture content in the air.

Damage to Electronic Components: Moisture inside the positioner's circuit board and sensors can cause short circuits or corrosion, leading to abnormal signal transmission (e.g., failure of stroke feedback or delayed control).

Mechanical Sticking: Moisture mixed with dust and rust in the air forms scale or sludge that can accumulate on movable parts such as the valve core, diaphragm, and springs, causing sluggish movements (e.g., imprecise valve position adjustments or increased backlash).

Accelerated Diaphragm Aging: Long-term exposure to moisture causes the rubber diaphragm to swell, crack, and lose elasticity, reducing its lifespan from 2-3 years to just 6-12 months.

Thoroughly dismantle the positioner (following the manual to avoid damaging seals). Blow dry any internal moisture with clean compressed air, and remove any scale (use soft brushes and neutral detergents; avoid sanding precision components).

Key checks: Inspect the diaphragm for damage, verify if the valve core or seat is stuck, and check for oxidation marks on the circuit board (if solder joints are blackened, replace the positioner instead of repairing it).

After cleaning, reinstall the positioner and connect it to a clean air source (consider using external high-purity nitrogen or temporarily filtered compressed air). Input a 4-20mA signal and test the valve's action.

Observe for any lag, jerking, or no movement. If the backlash exceeds 3% (standard for smart positioners is ≤1%), the mechanical parts are damaged, and replacement is recommended.

Test the communication function (e.g., HART protocol). If there is signal interruption or data anomalies, this indicates that the electronic module has failed due to moisture and needs to be replaced.

Refrigerant Dryers: Reduce compressed air dew point to below -20°C (water content <0.8g/m³), preventing condensation in subsequent pipelines.

Oil-Water Separators: Install after the refrigerant dryer with a filtering precision ≥1μm to separate remaining liquid water and oil impurities. Choose models with automatic drainage to prevent manual delays.

Air Tanks: Regularly manually drain the tanks once a day. If high humidity is a concern, install automatic drainage valves for continuous moisture removal.

Precision Filters: Install a primary precision filter (0.1μm, with activated carbon filter) near the positioner to remove fine impurities and oil mist. This is especially critical for precision equipment like smart positioners.

Site Inspections and Adjustments:

Check if existing air source pipelines have "low points" where water may accumulate (e.g., improperly sloped pipes). Adjust the slope of the pipes to ≥3‰ towards the drain point.

If the positioner inlet does not have a filter or pressure reduction valve, install one (to filter impurities and stabilize pressure). Set the pressure slightly lower (by 0.1MPa) than the positioner's rated pressure.

|

Maintenance Item |

Frequency |

Key Standards |

|

Air Source Treatment Inspection Daily |

1. Check refrigerant dryer indicators, ensure outlet temperature ≤40°C. |

|

|

2. Oil-water separator liquid level should be <1/3, drain when needed. |

||

|

3. Filter differential pressure <0.05MPa (replace filter if exceeded). |

||

|

Positioner Sealing Check |

Monthly |

Inspect the positioner inlet and wiring box for any condensation. |

|

Diaphragm/Valve Core Wear Detection |

Quarterly |

Disassemble the actuator and check for diaphragm cracks or rust spots. |

|

Smart Positioner Calibration |

Semi-Annually |

Perform "valve travel calibration" using a hand-held device (e.g., 475) to ensure linearity error <1%, backlash <0.5%. |

Direct Losses: Replacement cost of the positioner (typically 10,000-50,000 CNY) + downtime repair labor costs (in industrial scenarios, 1 hour of downtime can cost tens of thousands).

Indirect Risks

Positioner failure can result in uncontrolled process parameters (e.g., temperature/pressure out of limits), leading to equipment damage or safety incidents (e.g., gas regulation valve closure causing system shutdown or overpressure).

Scale entering the actuator can cause diaphragm rupture, leading to sudden full valve opening/closing, requiring emergency shutdown.

Core Logic: Compressed air is like the "blood" for smart positioners, high moisture content = "contaminated blood," which will inevitably lead to early failure.

Action Recommendations

Immediately inspect the air source pipeline for proper dehydration and oil removal equipment (prioritize checking refrigerant dryer operation and oil-water separator drainage).

If the positioner has serious internal scale or moisture-damaged electronic components, replace it immediately to avoid "running with issues" and further damage.

Emphasize to customers: Air source treatment is not optional; it's a "must-have" protection, especially for smart positioners (recommend including air source quality checks in the equipment acceptance standards before production).

By addressing current faults and preventing future risks, this dual approach not only resolves the immediate problem but also avoids similar issues, reducing long-term operation and maintenance costs.