After the valve is assembled, it undergoes a water pressure test and a 0.6 MPa air pressure test. The air pressure test is conducted with qualified materials and begins with the helium test.

Helium test for strength and sealing, with a pressure of 0.4 MPa helium gas. The strength test result shows that the filling leaks exceed the standard, but there is no leakage after tightening the cover.

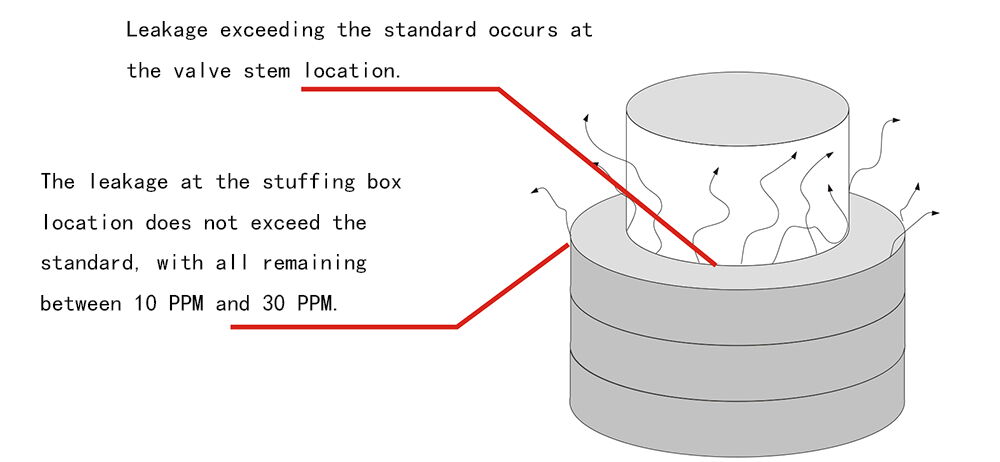

Conduct switch cycle testing. During the cycle test from 100 to 500 cycles, there is no leakage exceeding 100 PPM. A test is conducted every hundred cycles, separately in dynamic and static conditions. The leakage during motion fluctuates randomly between 10 PPM and 50 PPM. The static leakage is between 10 PPM and 20 PPM.

When the cycle reaches 600 times, the leakage exceeds the standard, ranging between 100 PPM and 120 PPM. This is the result of the test conducted during motion. After tightening the cover, the leakage returns to between 10 PPM and 20 PPM.

During the period from 700 to 1500 cycles, The leakage during motion fluctuates randomly between 20 PPM and 100 PPM. The static leakage is between 20 PPM and 40 PPM.

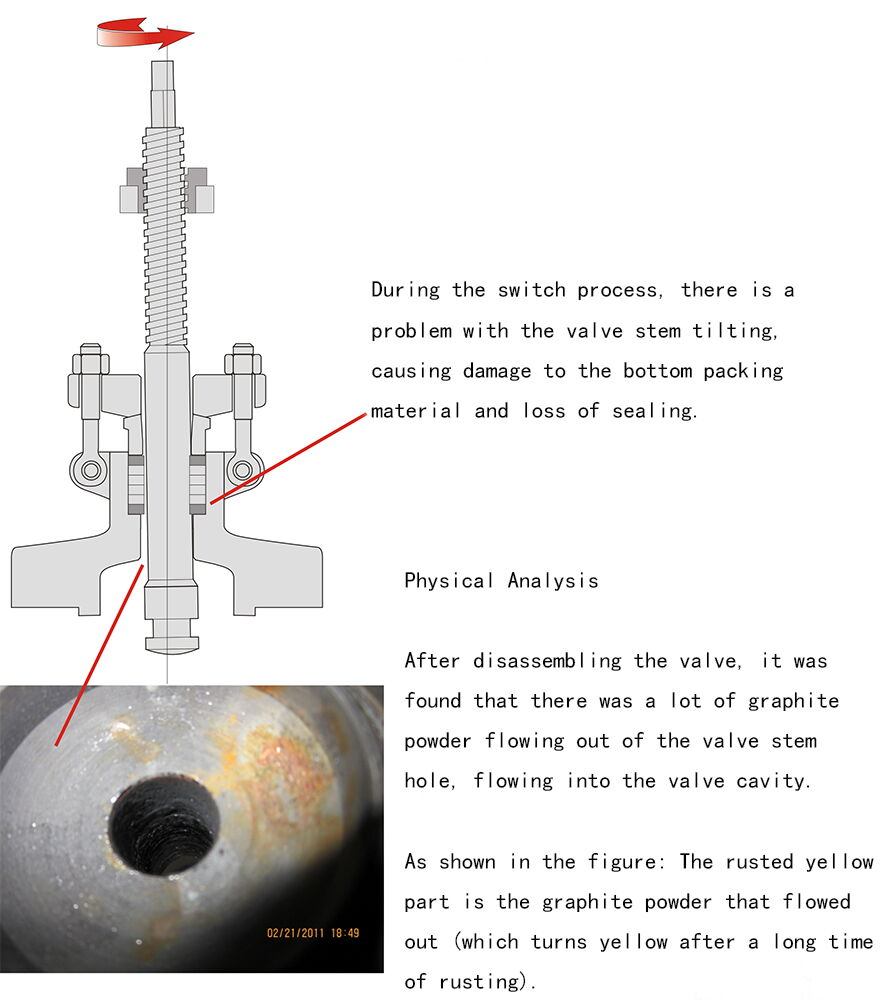

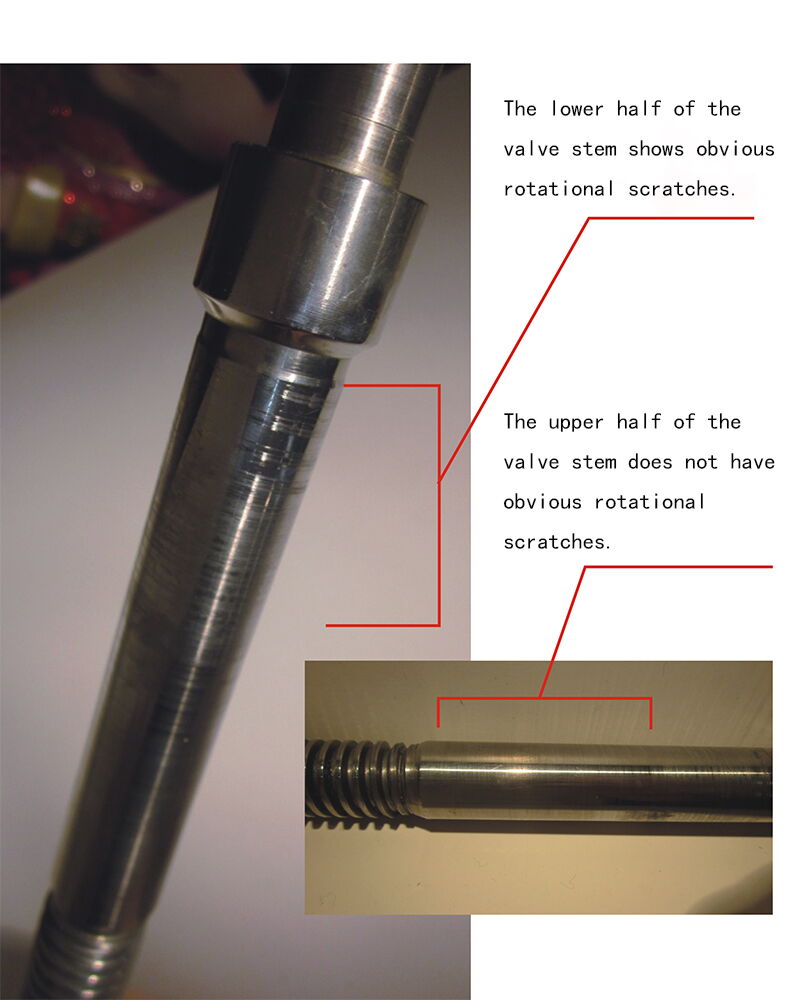

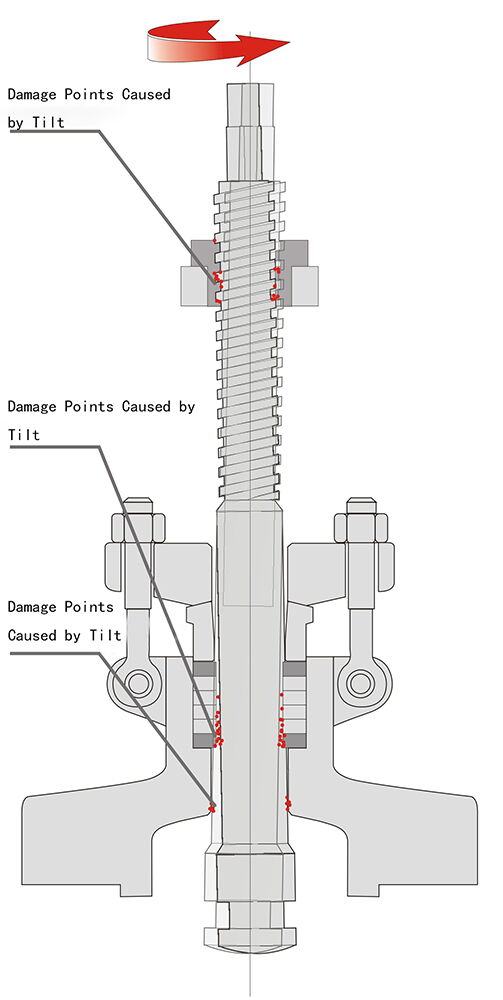

The difference between the test valve and the cut-off valve is that the valve stem rotates. The concentricity requirement for the upper cover is extremely high. The gate valve has a certain amount of movement clearance between the nut and the valve stem.

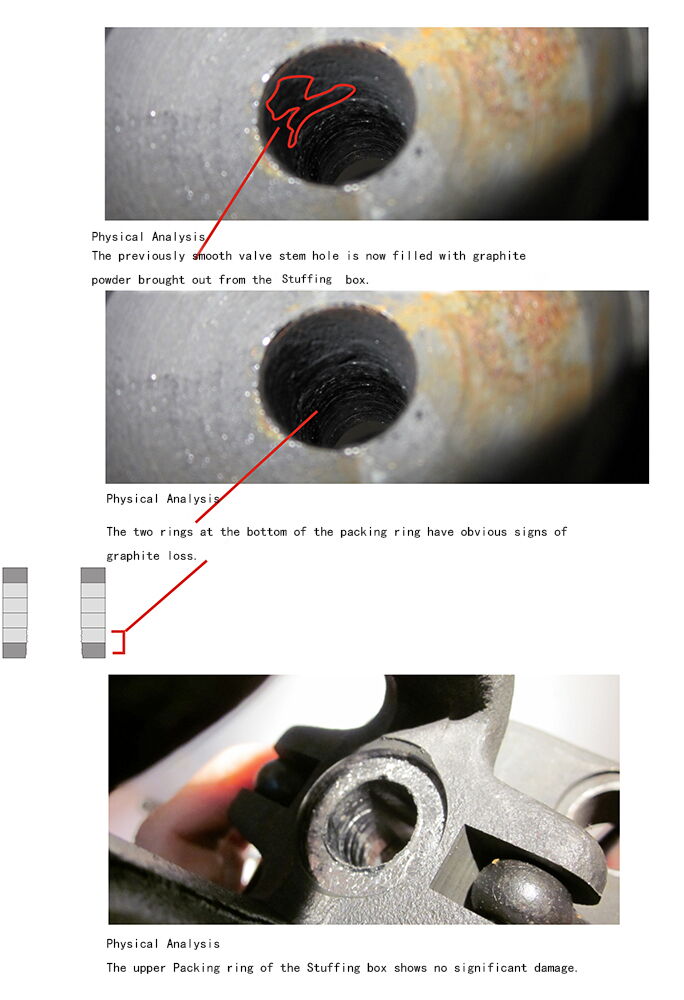

The valve stem tilt issue causes damage to the bottom filling ring. The more the number of switch cycles, the greater the damage to the bottom filling ring. It also directly causes the stem to be scratched by the nut.

This is why there is a leakage of 20PPM to 50PPM to 100PPM during motion.

The leakage exceeding the standard is not caused by the filling ring. It may be due to the different concentricity between the machine and the switch, and the different concentricity between the test instrument and the valve, causing the valve stem to tilt and damage the filling ring, losing sealing.