In the industrial sector, bolted flange connection systems are an indispensable part of connecting pipelines and containers. The performance of the gasket within this system is crucial, as it directly affects the reliability of the seal. Today, let's delve into the topic of gasket stress and understand how it impacts the sealing performance of the entire connection system.

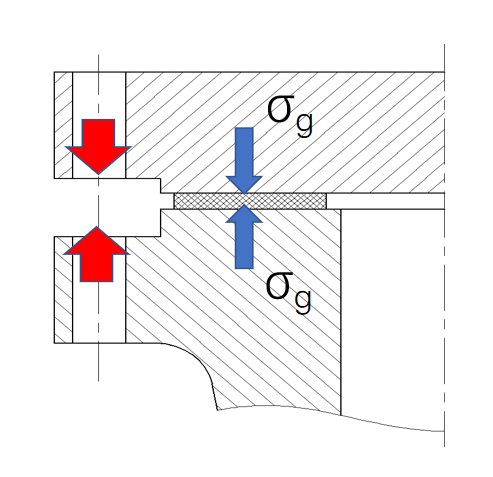

Gasket stress refers to the compressive stress acting on the gasket. In a bolted flange connection system, gasket stress plays a central and critical role, determining the sealability of the connection. When bolts are tightened, an initial bolt load is generated, which acts on the gasket to create gasket stress. However, not all gasket stress is directly used to control leakage. Only a portion of it is closely related to leakage control, while the rest is needed to counteract the thrust generated by the fluid static pressure acting on the ends of the pipeline or container.

Fluid static pressure is one of the significant factors affecting gasket stress. When a pipeline or container is filled with fluid, the fluid generates static pressure, which exerts an outward thrust on the ends of the pipeline or container. To maintain the stability of the connection, a part of the gasket stress must be used to counteract this thrust. In high-pressure situations, the thrust generated by fluid static pressure can become extremely large, causing most of the initial bolt load to be used to balance this thrust, thereby reducing the gasket stress actually used for sealing.

For example, assume that the fluid pressure in a pipeline system is 10 MPa and the diameter of the pipeline is 500 mm. The thrust generated by the fluid static pressure can be calculated using a formula. In this example, the magnitude of the thrust is approximately 196,350 N. If the initial bolt load on the gasket is 200,000 N, then a large portion of it (about 196,350 N) will be used to resist this thrust, leaving only a small part (about 3,650 N) for actual sealing. It is evident that in high-pressure environments, the effective portion of gasket stress is significantly reduced, placing higher demands on sealing performance.

Before the fluid pressure acts, the gasket must withstand the initial bolt load. The magnitude of this load directly affects the stress condition of the gasket and its sealing performance. If the initial bolt load is too high, it may exceed the gasket's tolerance, leading to gasket damage. For instance, if the maximum stress that the gasket can withstand is 100 MPa, and the stress generated by the initial bolt load exceeds this value, the gasket may experience deformation, rupture, or other issues, thereby affecting the sealing performance.

Joints of different sizes have differences in structure and stress conditions. Therefore, even if the same type of gasket is used, the working pressure range they can handle will vary. For example, for small-sized joints, due to their smaller stress area, the gasket may be able to withstand higher pressure. In contrast, for large-sized joints, due to the larger stress area, the gasket needs to withstand a greater load, and thus its applicable working pressure range will be relatively lower.

To enhance the sealing performance of bolted flange connection systems, it is necessary to optimize gasket stress. First, during the design phase, appropriate gasket materials and dimensions should be selected based on actual operating conditions to ensure that the gasket can withstand sufficient initial bolt load and maintain good sealing performance under fluid pressure. Second, during the installation process, bolts should be pre-tightened strictly according to the specified torque to avoid excessive or insufficient initial bolt load. Additionally, some auxiliary measures can be adopted, such as increasing the thickness of the gasket or using multi-layer gaskets, to improve the sealing performance and pressure resistance of the gasket.

Gasket stress is a key element in bolted flange connection systems, directly affecting the reliability of the seal. In practical applications, it is essential to fully consider the impact of fluid static pressure on gasket stress, select gasket materials and dimensions reasonably, and optimize the initial bolt load to ensure the sealing performance of the connection system. With the continuous development of technology, it is believed that more advanced materials and methods will be applied to the design and manufacturing of gaskets, further improving the sealing performance and reliability of bolted flange connection systems.

In the upcoming series of articles, we will provide detailed introductions to the main characteristic properties of sealing gaskets, helping everyone gain a deeper understanding of the important role of gaskets in industrial connections.