In industrial production, sealing technology is a crucial component in ensuring the safe operation of equipment. Gaskets, as key parts in flanged joints, play a vital role in determining the effectiveness of a seal. Today, we will delve into the load-deformation behavior of gaskets and explore how it impacts sealing performance.

The load-deformation relationship of a gasket is one of the core indicators for assessing its mechanical properties. In simple terms, this relationship is evaluated by observing the deformation of the gasket under different stress levels. Specifically, we typically use the gasket stress σg and the corresponding deformation δg under that stress to represent this relationship, although sometimes we may directly describe it in terms of the applied force.

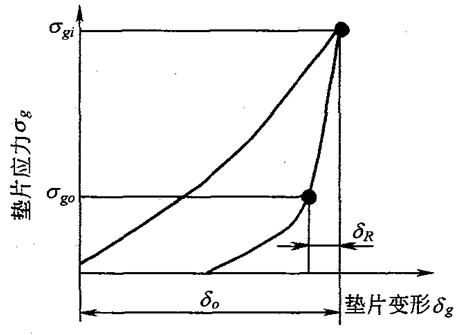

To better understand this concept, we can visualize a gasket as a spring. When pressure is applied to a spring, it deforms; when the pressure is released, the spring returns to its original shape. Similarly, during operation, a gasket undergoes compression deformation when the flanged joint is assembled. This initial deformation, denoted as δo, occurs under the initial installation stress σgi. As the equipment begins to operate and the medium exerts pressure on the gasket, the gasket stress decreases, and the gasket rebounds. This rebound, represented by δR, is highly critical as it directly affects the sealing performance of the gasket during operation.

The compression and rebound elasticity of a gasket is an important aspect of its load-deformation behavior. Excellent rebound elasticity means that the gasket can quickly return to a shape close to its initial state after being compressed. This characteristic is crucial for maintaining a good seal.

In practical applications, for example in FLT joints, the rebound amount of the gasket is a significant performance indicator. If the rebound is insufficient, the gasket may undergo permanent deformation under the medium's pressure, creating gaps between the sealing surfaces and leading to leaks. Conversely, if the gasket has good rebound elasticity, it can quickly recover once the medium's pressure is removed, filling the gaps between the sealing surfaces and maintaining a good seal.

Understanding the load-deformation behavior of gaskets helps us clearly grasp the state changes of gaskets from installation to operation. This understanding is foundational for subsequent analysis of gasket performance and optimization of sealing design.

When designing a sealing system, we need to select appropriate gasket materials and dimensions based on the load-deformation curve of the gasket. For instance, if a device operates under high pressure, a gasket with high initial installation stress and good rebound elasticity should be chosen to ensure sealing performance under the thrust of high-pressure media. Additionally, we must consider the material properties of the gasket, such as temperature adaptability and chemical stability, as these factors can also affect the load-deformation behavior of the gasket.

In practical applications, attention to certain details is necessary to ensure that the load-deformation behavior of the gasket reaches its optimal state. First, during gasket installation, it is crucial to follow the specified initial installation stress to avoid excessive or insufficient stress. Excessive installation stress can lead to over-compression of the gasket, affecting its rebound elasticity, while insufficient stress may fail to ensure initial sealing effectiveness.

Second, during equipment operation, regular inspection of the gasket's sealing condition is essential. If leakage is detected, the cause should be promptly analyzed. It could be due to insufficient rebound elasticity or aging and damage of the gasket material. Different issues require corresponding measures, such as replacing the gasket or adjusting the installation stress.

Through the in-depth analysis of the load-deformation behavior of gaskets, it becomes evident that this seemingly simple mechanical property holds the key to ensuring the safe and efficient operation of industrial seals. From the explanation of its basic concepts to the critical role of compression and rebound elasticity, to its significant impact on sealing design, and the meticulous considerations in practical applications, each aspect is closely interconnected and interdependent.

For low-emission sealing challenges, Magpie Sealing offers proven solutions. If you have technical questions or want to explore more about sealing technologies, follow us, leave a comment, or get in touch. We welcome your inquiries and discussions!

Stay tuned for our next issue as we continue our series on sealing gasket types. See you next time!