In the industrial sector, sealing technology is a crucial element in ensuring the safe operation and efficient functioning of equipment. Gaskets, as an indispensable part of sealing systems, have their sealing performance influenced by a variety of factors, among which surface roughness plays a vital role. This article will delve into the impact of surface roughness on gasket sealing performance, helping readers better understand this phenomenon.

Surface roughness refers to the micro-geometric shape characteristics of a machined surface, composed of small spacing and peaks and valleys. It is typically measured using height characteristic parameters, the most commonly used being the arithmetic mean deviation of the profile (Ra) and the maximum height of the profile (Rz).

Ra is the arithmetic mean of the absolute values of the profile deviations within the sampling length (Lr). In simple terms, it reflects the average roughness of the surface. In practical measurements, the more measurement points there are, the more accurate the Ra value will be. The smaller the Ra value, the smoother the surface; the larger the Ra value, the rougher the surface.

Rz is the distance between the peak and valley lines of the profile, representing the maximum variation range of surface roughness. Rz can intuitively reflect the unevenness of the surface and is very useful for assessing extreme roughness conditions.

Surface roughness has a multifaceted impact on the performance of mechanical parts. It is closely related to the fit characteristics, wear resistance, fatigue strength, contact stiffness, vibration, and noise of the parts, thereby affecting the service life and reliability of mechanical products.

Rough surfaces generate greater friction during fitting, which can lead to uneven fit clearances and affect the assembly accuracy and motion flexibility of the parts. Smooth surfaces, on the other hand, can better ensure the uniformity of fit clearances, improving assembly quality and motion performance.

Surface roughness affects the wear resistance of parts. During relative motion, sharp peaks on rough surfaces are easily worn away, leading to increased surface wear. Appropriate surface roughness, however, can form a certain oil film, reducing direct contact and thereby enhancing wear resistance.

Surface roughness also has a significant impact on the fatigue strength of parts. Rough surfaces can cause stress concentration, reducing the fatigue strength of the parts. By controlling surface roughness, stress concentration can be reduced, thereby increasing the fatigue life of the parts.

When rough surfaces come into contact, the actual contact area is small, resulting in low contact stiffness. Smooth surfaces, however, can increase the actual contact area, thereby enhancing contact stiffness and improving the load-bearing capacity and stability of the parts.

Surface roughness can also cause vibration and noise. Rough surfaces generate more vibration and noise during motion, affecting the smooth operation of the equipment and the working environment. By optimizing surface roughness, vibration and noise can be effectively reduced, thereby improving the operational performance of the equipment.

Surface roughness has a direct impact on gasket sealing performance, mainly manifested in the following aspects.

Rough surfaces can reduce the tightness between the sealing element and the sealing surface, thereby increasing the likelihood of leakage. This is because rough surfaces have many small irregularities, which prevent the sealing surfaces from fitting together perfectly, creating leakage channels. For example, in high-precision sealing connections, if the roughness of the sealing surface is too high, even with high-quality gaskets, the desired sealing effect may not be achieved.

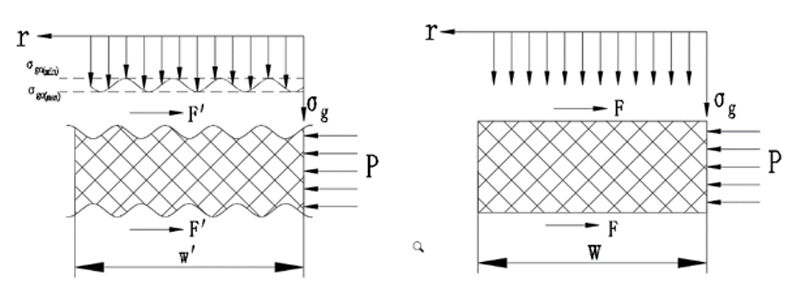

However, in some cases, appropriate surface roughness can actually improve sealing performance. This is because appropriate roughness can increase the "effective sealing face width," that is, w’>w. This means that although the actual width of the sealing surface does not change, the contact area between the sealing element and the sealing surface is increased due to the roughness, thereby enhancing sealing performance.

Different types of gaskets have varying sensitivities to surface roughness.

Metal Ring Gaskets

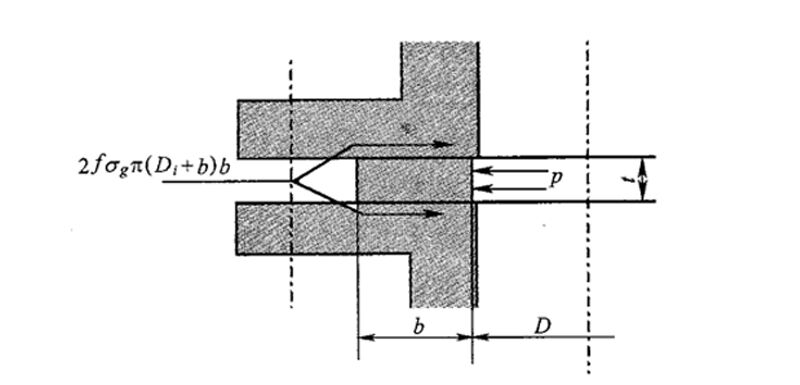

For line-sealing metal ring gaskets, such as metal elliptical gaskets, there is a "hard contact" between the gasket and the metal surface of the flange being sealed. In this case, roughness can lead to reduced engagement, thereby reducing tightness. Therefore, such sealing connections generally require the roughness of the sealing surface to be controlled to no more than 1.6μm.

Flexible Sealing Gaskets

For flat-sealing flexible gaskets, such as rubber gaskets, asbestos-free rubber gaskets, PTFE gaskets, and graphite wound gaskets, they have good engagement properties and can effectively "fill" the "irregularities" on the flange surface caused by "roughness." However, there are two prerequisites: First, the stress level in the valleys of the gasket, after engagement "filling," remains effective, that is, σgo’min is not lower than the effective working sealing stress; second, the "water ripples" formed during processing should preferably be concentric circles, especially when the roughness is close to 6.3μm. Using spiral lines (although allowed by ASME B16.5 Section 6.4.5.3) can affect the tightness of joints with higher sealing requirements.

For flat sealing, appropriate roughness can increase the friction between the sealing element and the surface being sealed, thereby enhancing the blowout resistance of the sealing element. This is because rough surfaces increase the number of contact points and the contact area, making it more difficult for the sealing element to be blown out when under pressure. This phenomenon is particularly important in high-pressure sealing applications, where appropriately increasing surface roughness can effectively enhance the reliability of the seal.

Surface roughness has a complex and significant impact on gasket sealing performance. It can both reduce tightness and increase leakage rates, as well as enhance sealing performance by increasing the effective sealing face width and friction. In practical applications, it is necessary to choose and control surface roughness reasonably according to specific sealing requirements and gasket types to achieve the best sealing effect. By deeply understanding the impact mechanism of surface roughness, engineers can better design and optimize sealing systems to ensure the safe operation and efficient functioning of equipment.

In summary, surface roughness is one of the key factors affecting gasket sealing performance. During the design and manufacturing processes, its impact on sealing performance should be fully considered, and surface roughness parameters should be chosen reasonably to meet different sealing requirements.