In engineering, sealing technology is a crucial factor in ensuring the safe operation of equipment. Whether in chemical plant pipelines, nuclear reactor systems, or everyday automotive engines, the quality of gasket sealing directly impacts the reliability and safety of the equipment. At the heart of sealing technology lies sealing stress; its origins and mechanisms have long been a focus of engineers. Today, we delve into the sources of gasket sealing stress, and explore the principles and applications of forced sealing, self-acting sealing, and semi-self-acting sealing.

Sealing stress refers to the stress acting on sealing components, determining the reliability and longevity of the seal. The two main sources of sealing stress are bolt load and medium pressure.

Bolt load is a primary source of sealing stress. In many devices, bolts fix the sealing element in place through clamping force, thereby achieving the seal. This sealing stress generated by bolt load is known as forced sealing.

The principle is straightforward: when bolts are tightened, they apply a downward force on the sealing element, pressing it firmly against the flange or valve contact surface to prevent leakage. The greater the bolt tightening force, the higher the pressure between the sealing element and the contact surface, thus improving sealing performance. However, this method demands high quality and proper tightening techniques for the bolts.

High-quality bolts are key to effective forced sealing. The material, strength, and size of bolts affect the magnitude and stability of the tightening force. For example, high-strength bolts maintain stable clamping under high pressure, whereas poor-quality bolts may loosen under pressure, causing sealing failure. Proper tightening methods are equally critical. The bolt torque must be adjusted according to actual working conditions to ensure the seal’s stability under high pressure. Excessive force may damage the seal, while insufficient force leads to leaks.

Forced sealing is widely used in bolted connections such as flanges, valves, and pumps. It effectively prevents leakage and ensures safe operation. For instance, in chemical pipelines, carefully designed bolt tightening ensures sealing performance under high temperature and pressure. Forced sealing is also known for its reliability and durability, maintaining good sealing under harsh conditions.

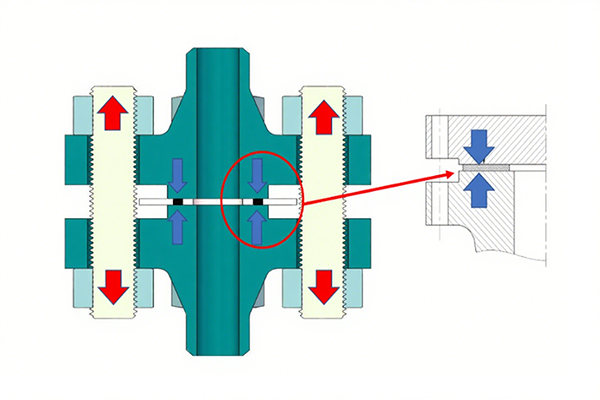

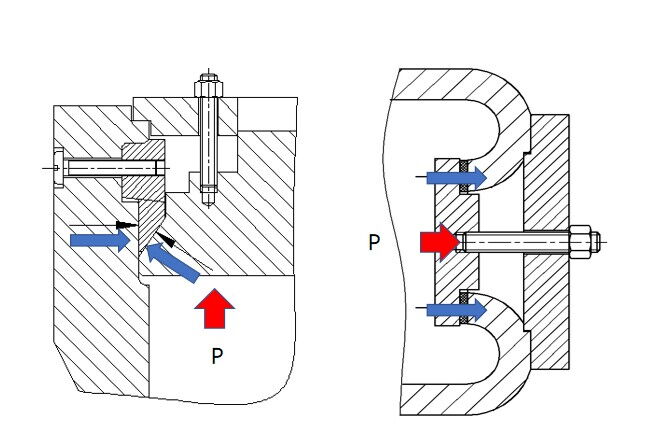

Besides bolt load, medium pressure is another critical source of sealing stress, characteristic of self-acting sealing. Self-acting sealing relies primarily on the pressure of the medium itself to generate sealing stress.

This principle is more complex. Initially, bolt load provides a baseline sealing stress, but as medium pressure increases, the sealing stress is increasingly borne by the medium pressure itself. The sealing stress can be calculated as:

Sealing Stress = Medium Pressure × (Area acted on by medium pressure / Parallel sealing contact area)

This formula shows the relationship between sealing stress, medium pressure, and sealing contact area: the higher the medium pressure or the larger the contact area, the greater the sealing stress.

Self-acting seals are widely used in pressure vessels, pipelines, and pumps. Typical examples include Wood seals and manhole cover seals. Wood seals use medium pressure to push the sealing ring tightly against the sealing surface. Manhole cover seals utilize the radial thrust generated by medium pressure to press the sealing element firmly. However, these designs have limitations; fluctuations in pressure and temperature can affect seal reliability, so the seal’s compressive strength must be carefully considered.

Self-acting seals automatically enhance sealing with rising medium pressure, improving operational efficiency and safety. On the downside, they tend to be bulky and complex to install or remove. Additionally, they are sensitive to pressure and temperature variations, requiring careful design tailored to the working conditions.

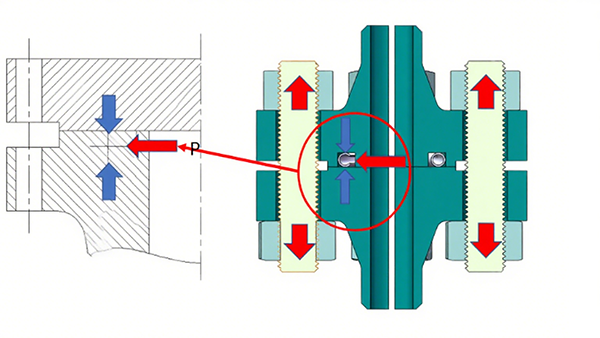

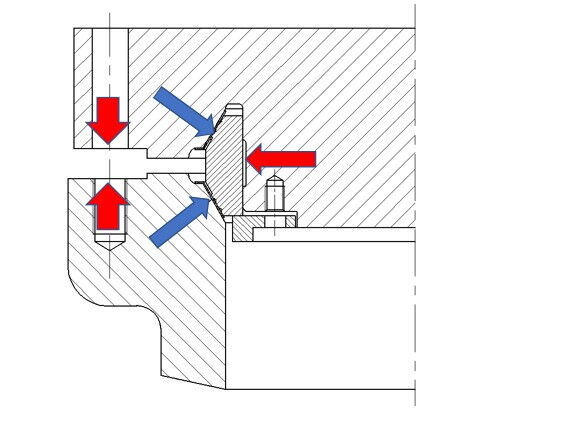

Besides forced and self-acting seals, there is a hybrid type known as semi-self-acting sealing, which merges their benefits and adapts to changes in both bolt load and medium pressure.

Semi-self-acting seals start with an initial sealing stress provided by bolt tightening, as in forced sealing. As medium pressure rises, the sealing stress automatically adjusts accordingly, enhancing the seal. This approach is especially suitable for medium to high pressures and fluctuating conditions.

Semi-self-acting seals are widely used in industry. For example, the internal opening C-ring seal maintains stable sealing in high-pressure environments. Another example is the double-cone ring gasket, where the main bolts apply the initial sealing force, and increasing pressure exerts radial thrust inside the ring to further improve sealing. This structure is ideal for nuclear power plants and other applications demanding exceptional sealing performance.

The advantage of semi-self-acting seals lies in their ability to combine forced and self-acting sealing benefits, automatically adjusting to pressure changes for superior sealing. However, some structures like double-cone ring seals are sensitive to alternating high and low temperatures, requiring attention to seal compressive strength and thermal adaptability.

Understanding the principles and applications of forced, self-acting, and semi-self-acting seals, it is crucial to select the appropriate sealing method based on actual conditions. Key factors to consider include:

Different equipment and environments require different sealing stress. High pressure and temperature demand seals capable of withstanding such conditions, while fluctuating pressure and temperature benefit from semi-self-acting seals with automatic adjustment capabilities.

Seal materials and design significantly affect performance. High-quality materials maintain sealing under harsh conditions, and good design improves compressive strength and adaptability. For instance, O-rings are elastic and can adjust sealing stress with pressure changes, making them widely used.

Bolt quality and tightening directly impact forced sealing effectiveness. High-quality bolts ensure stable sealing under high pressure, preventing leaks. Proper tightening ensures even distribution of clamping force, enhancing sealing. Bolt selection and tightening should align with working conditions.

Sealing stress is the core of sealing technology, originating mainly from bolt load and medium pressure. Forced sealing relies on bolt load, offering high reliability and durability; self-acting sealing depends on medium pressure and adapts automatically to pressure changes; semi-self-acting sealing combines both advantages, accommodating varying bolt loads and medium pressures. Selecting and optimizing sealing methods based on operating conditions, sealing material/design, and bolt quality/tightening ensures better sealing performance. Continuous improvement in sealing technology provides safer, more efficient sealing solutions to guarantee the reliable and safe operation of diverse equipment.