In the industrial sector, valves are crucial components for controlling fluid flow, and packing is the core element that ensures the sealing performance of valves. Improper installation of packing can lead to minor issues like leakage or, in severe cases, trigger safety accidents and cause significant economic losses. Therefore, mastering the correct method of installing valve packing is of utmost importance. This article will provide you with a detailed introduction to the entire process of installing valve packing, from preliminary preparations to final tightening and debugging, making it easy for you to handle the installation of valve packing.

The preliminary preparations are the key first step in ensuring the sealing performance during the installation of valve packing. Only with thorough preparations can a solid foundation be laid for the subsequent installation work. Next, we will elaborate on several important aspects of preliminary preparations.

Selecting the right packing is the first step in installing valve packing. There are various types of packing available, with common ones including braided packing and graphite packing. When choosing packing, it is essential to take into account the form of the packing box as well as factors such as the pressure, temperature, and corrosiveness of the medium. The surface of braided packing should be smooth and clean, free from defects like abrasions, skipped stitches, filler shedding, and deterioration. Only high-quality packing can provide a reliable guarantee for sealing performance.

Before installing the packing, it is also necessary to prepare a series of tools, such as packing tools and packing cutting tools. These tools may seem simple, but they play an indispensable role in the installation process. For example, packing tools can help us evenly press the packing into the packing box, preventing the packing from becoming loose or piled up.

A comprehensive inspection of the valve before installation is an important step in ensuring sealing performance. First, verify the specifications and model of the valve to ensure that they match the actual usage requirements. Then, carefully inspect the valve for any damage, especially the valve stem. The valve stem can easily be bent during transportation, so it requires special attention. In addition, turn the valve stem a few times to ensure that it is not skewed and that there are no foreign objects inside the valve. Although this step may seem cumbersome, it can effectively prevent packing seal failure caused by valve stem issues and extend the service life of the valve.

Determining the cross-sectional dimensions of the packing is a crucial step before installation. First, measure and record the diameter of the valve stem, as well as the depth and inner hole diameter of the packing box. Then, subtract the valve stem diameter from the inner hole diameter and divide the difference by two to obtain the required packing cross-sectional dimensions. Finally, add these two diameters together to calculate the required length of each section of packing. Only precise dimensions can ensure a tight fit between the packing and the valve stem and packing box, laying a solid foundation for sealing performance.

The cutting of braided packing has a vital impact on its performance and service life. The correct cutting method can ensure that the packing fits tightly after installation, reducing the risk of leakage. Here are two common methods for cutting braided packing:

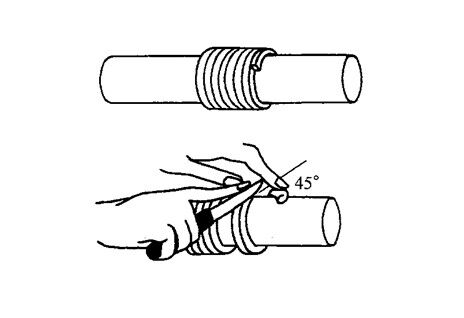

First Cutting Method: This method involves cutting the continuous roll of packing into individual rings. During cutting, a mandrel with the same diameter as the valve stem can be used. Hold the packing wound around the mandrel, but not too long, and cut the ring at a 45° angle to the axis. Then, carefully separate the ring along the axis. The advantage of this cutting method is that it is relatively simple to operate and is suitable for quick on-site cutting of packing. However, it is important to maintain a smooth cutting surface during the process, avoiding frayed edges or notches, as these can affect the sealing performance of the packing.

Second Cutting Method: Using a packing cutting tool to cut along a 45° angle, calculate the length based on the mid-diameter, add the cross-sectional dimension, and then cut the other end. This is a commonly used method at present. The use of a professional packing cutting tool can ensure the precision and quality of the cut, resulting in a smoother and more even end face of the packing. During the cutting process, it is essential to strictly follow the calculated length to ensure that each packing ring is of consistent size, thereby guaranteeing the sealing effect after installation.

The installation of braided packing is a process that requires meticulous attention to detail, as every step can affect the sealing performance. Here are several key points to note when installing braided packing.

When cutting braided packing, before cutting along the 45° angle, it is necessary to first remove 9°-12° of the packing in the vertical direction. This is done to prevent gaps caused by inconsistent circumferences after the ring is joined, which could pose a risk of forming a leakage channel. Although this detail may seem minor, it can effectively enhance the sealing performance of the packing.

Place the cut packing onto the valve stem one by one through the cut, and position it inside the packing box. During the installation process, check whether the packing fits well with the packing box cavity. When installing each ring, use the packing tool to press it tightly, ensuring there are no gaps between the packing. Before installing the next ring, always check whether the previous ring has been compacted and leveled. The seams between the rings should be staggered and kept at least 90° apart. This can prevent concentrated stress at the seams and reduce the possibility of leakage. After all the rings have been installed one by one, lower the gland so that the front end of the gland contacts the end face of the packing ring.

After the packing installation is completed, it is necessary to perform loading and tightening and valve stem movement to ensure that the sealing performance reaches the optimal state. Here are two common methods for loading and tightening.

First Loading Method: Compress the entire packing assembly, and if possible, record the torque value of the gland nut. Then move the valve stem up and down 5 to 6 times (with the valve stem finally in the downward position). After each movement, retighten the gland nut to the previously recorded torque value. This loading method is simple and easy to perform, suitable for on-site operations. By moving the valve stem up and down multiple times, the packing can gradually adapt to the movement of the valve stem under stress, thereby better fulfilling its sealing function.

Second Loading Method: Based on the stress characteristics of the sealing packing, combined with the medium pressure and the basic properties of the packing used (compression rate, pressure coefficient, friction coefficient), calculate the required sealing working stress σg. This can accurately determine the tightening torque required for the gland nut. Then move the valve stem up and down 6 times (with the valve stem finally in the downward position). After each movement, retighten the gland nut to the previously recorded torque value. This method is relatively more complex, but it can more precisely control the sealing performance of the packing and is suitable for applications with high sealing requirements.

The installation of valve packing is an engineering task that appears simple but is full of details. From preliminary preparations to the cutting and installation of packing, and finally to the loading and tightening, every step is of great importance. By carefully selecting packing, thoroughly inspecting the valve stem, accurately measuring dimensions, mastering the correct cutting methods, paying attention to installation details, and reasonably loading and tightening, we can effectively avoid packing seal failure and ensure the long-term stable operation of the valve.

In actual operation, we also need to continuously accumulate experience and flexibly apply the knowledge we have learned according to different valves and working conditions. Only in this way can we fully utilize the role of valves in industrial production and ensure the safety and efficiency of production. We hope that the introduction in this article can be of help to you and make you more proficient in the installation of valve packing.