In industrial piping systems, valves not only perform the essential functions of opening, closing, and regulating the flow of media, but also have a direct impact on the safety, reliability, and economic performance of the entire installation. Among the many performance indicators of a valve, sealing performance has always been at the core. In particular, the valve backseat (upper seal), as a critical structural feature, plays an irreplaceable role during inspection, maintenance, and abnormal operating conditions. Whether the backseat design is reasonable, and whether its manufacturing and testing processes are properly executed, directly determines the valve's long-term leakage prevention capability and service life. This article provides a systematic discussion of the importance of valve sealing, the design principles of valve backseats, manufacturing processes, testing methods, and practical applications, helping readers gain a comprehensive understanding of the engineering value and application essentials of valve backseat technology.

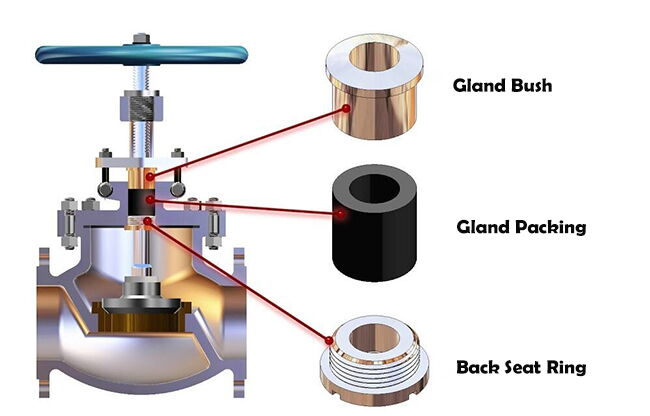

The primary function of a valve is to control fluid flow. Whether used for shut-off, regulation, or throttling, sealing performance is the core criterion for evaluating valve quality. The main sealing areas of a valve include the sealing surface between the closure member and the seat, the contact area between the stem and the bonnet, the stem sealing area, and the gasketed joint between the valve body and the bonnet. Leakage between the closure member and the seat is referred to as internal leakage, while leakage at the stem, bonnet, stem sealing, or the body-to-bonnet sealing surface is known as external leakage.

Internal leakage directly affects the valve's ability to isolate the medium, reducing production efficiency and potentially causing product quality issues. External leakage is even more serious, as it not only results in loss of the conveyed medium but may also pollute the environment and, in severe cases, lead to major safety incidents. For flammable, explosive, toxic, or radioactive media, external leakage is absolutely unacceptable. Therefore, ensuring reliable valve sealing performance is a critical and indispensable aspect of industrial production.

The sealing performance of a valve backseat is an important technical indicator of overall valve quality. National standards specify technical requirements for backseats in steel gate valves and steel globe valves. The effectiveness of the backseat seal is closely related to multiple factors, including valve materials, machining equipment, tooling manufacture, heat treatment, machining processes, geometric tolerances, and component dimensional accuracy. Any deviation from design requirements in these areas will directly affect backseat performance.

Traditional backseat structures are mainly conical or spherical in form. Although these designs can theoretically provide good sealing performance, they present several disadvantages in practical applications. For example, friction exists between the sealing surfaces, maintenance is difficult, and machining is complex, resulting in increased production costs. Moreover, after several sealing performance tests, these backseat designs often tend to fail.

To overcome these drawbacks, valve designers have explored new sealing structures. An effective improvement is to apply the flat-face sealing principle used in globe valve discs, replacing the original conical contact between the stem and bonnet with a flat contact configuration. This flat-contact sealing structure is simple, easy to machine, and largely unaffected by equipment accuracy, tooling precision, or geometric tolerances of mating parts. After hardfacing the bonnet sealing area, only precision turning is required to meet design requirements. Once the valve stem is finish-machined, its head is heated to the quenching temperature and air-cooled to room temperature, after which the sealing surface is finish-turned and assembled. With this improved design, the one-time pass rate of backseat testing can reach 100%, the service life matches the number of valve operating cycles, and maintenance is convenient.

For stainless steel valves, the stem and bonnet are typically made of the same austenitic material. When pressed together, they tend to exhibit galling, which adversely affects sealing performance. Therefore, conical backseat designs are generally avoided for stainless steel valve bonnets. Instead, a sealing bore can be machined below the packing chamber in the bonnet, using the conical surface on the valve stem together with a PTFE conical sealing gasket as the sealing pair. This structure is particularly suitable for pipelines handling corrosive media.

The manufacturing process of valve backseats plays a decisive role in sealing performance. From material selection to machining accuracy, every step must be strictly controlled.

Valve materials directly affect sealing performance and service life. Common materials for steel gate valves and globe valves include carbon steel, stainless steel, and alloy steel. Carbon steel is suitable for general industrial environments, while stainless steel, with its excellent corrosion resistance and mechanical properties, is widely used in chemical, pharmaceutical, and other industries with special media requirements. Alloy steel is used under extreme conditions such as high temperature and high pressure.

For backseat structures, material selection for the bonnet and stem is particularly important. When both are made of the same austenitic stainless steel, galling is likely to occur under pressure, impairing sealing performance. Therefore, the backseat sealing surface on the bonnet is typically hardfaced. The hardfacing material may be austenitic stainless steel or a hardfacing alloy, with a finished thickness of not less than 1.6 mm. For globe valves smaller than DN50, it is recommended to directly hardface and then machine the sealing surface.

The machining process of valve backseats includes mechanical machining, heat treatment, and surface treatment. Machining accuracy directly affects the flatness and mating precision of the sealing surfaces. High-precision equipment and advanced machining techniques form the foundation of reliable sealing performance. Heat treatment enhances material hardness and wear resistance while relieving machining stresses. Surface treatments such as hardfacing and coatings further improve corrosion and wear resistance.

In practice, after hardfacing, the bonnet sealing area must be finish-turned to ensure flatness and accuracy. After finish machining, the valve stem head is heated to the quenching temperature and air-cooled to room temperature, followed by finish turning of the sealing surface and final assembly. This process effectively ensures reliable backseat sealing performance.

Backseat testing is a crucial step in ensuring sealing performance. Proper testing methods can identify potential issues early and prevent leakage incidents during actual operation.

The backseat test is conducted as follows:

- Seal the valve inlet and outlet: Ensure that both inlet and outlet are completely sealed to prevent test medium leakage.

- Loosen the packing gland: If the valve is equipped with a backseat inspection device and the backseat performance can be reliably checked without loosening the packing gland, this step may be omitted.

- Fully open the valve: Open the valve so that the backseat is engaged.

- Pressurize the cavity: Fill the cavity with the test medium and gradually increase pressure to the specified test pressure.

- Pressure holding and inspection: After the specified holding time, inspect the backseat performance. Leakage within the allowable limit is considered acceptable.

Backseat testing includes high-pressure and low-pressure tests.

The high-pressure backseat test pressure is 1.1 times the maximum allowable working pressure at 38 °C. The test medium may be water, air, kerosene, or similar fluids.

The low-pressure backseat test pressure is 0.4–0.7 MPa, with air or inert gas as the test medium.

In practice, two incorrect testing methods are commonly observed:

Conducting shell and backseat tests simultaneously: The shell pressure test is performed at 1.5 times the maximum allowable working pressure at 20 °C, while the sealing test pressure is 1.1 times the maximum allowable working pressure at 20 °C. Since the pressures differ, simultaneous testing often results in overpressure on the backseat, packing damage, and reduced service life.

Testing only the disc seal while neglecting the backseat: If only the disc sealing test is performed and the backseat test is omitted, problems may arise during packing replacement. If the backseat cannot effectively seal and there is no other valve to isolate the pipeline or equipment, the medium must be drained, the valve removed, and the packing replaced—an operation that is time-consuming, labor-intensive, disruptive to production, and costly.

Therefore, backseat testing must be performed strictly in accordance with applicable standards to ensure accuracy and reliability.

In industrial applications, backseat performance directly affects production efficiency and operational safety. The following considerations are recommended.

When opening a valve, the closure member should reach its full position so that the backseat can perform its intended function. However, operating force should be applied gently and appropriately, not excessively or too rapidly, to avoid damaging the sealing surface. Proper operation extends the service life of the backseat and prevents hazards associated with external leakage.

Regular maintenance is essential to ensure backseat performance. During maintenance, the sealing surfaces should be inspected for wear, and damaged sealing components should be replaced promptly. For valves equipped with backseats, replacing packing under pressure is not permitted, as it poses significant safety risks. The pipeline medium may be water, high-temperature steam, or acidic or alkaline substances, and even minor leakage can lead to accidents.

Valve selection should be based on actual operating conditions. For pipelines conveying corrosive media, structures using PTFE conical sealing gaskets should be selected. For high-temperature and high-pressure applications, alloy steel valves should be used, and the backseat structure must be capable of withstanding the corresponding pressure and temperature.

Valve backseats are an indispensable key technology in industrial production. Through reasonable sealing structure design, strict manufacturing processes, and standardized testing methods, valve sealing performance can be significantly improved, production costs reduced, operational efficiency enhanced, and the safe and stable operation of production systems ensured. In practical applications, correct operation and regular maintenance are essential safeguards for reliable backseat performance. It is hoped that this article will help readers better understand and apply valve backseat technology, contributing to safer and more efficient industrial production.