Magpie Sealing Technology Insights

Flanges and Gaskets – Sealing Gasket Types (Part 12): Metallic Ring Gaskets: Structure, Performance and Application

In industrial operations, the performance of gaskets directly impacts the stability and safety of equipment. In our previous article, we explored flat metal gaskets and serrated metal gaskets. Today, we turn our attention to metallic ring gaskets, highlighting their structural advantages and key application areas.

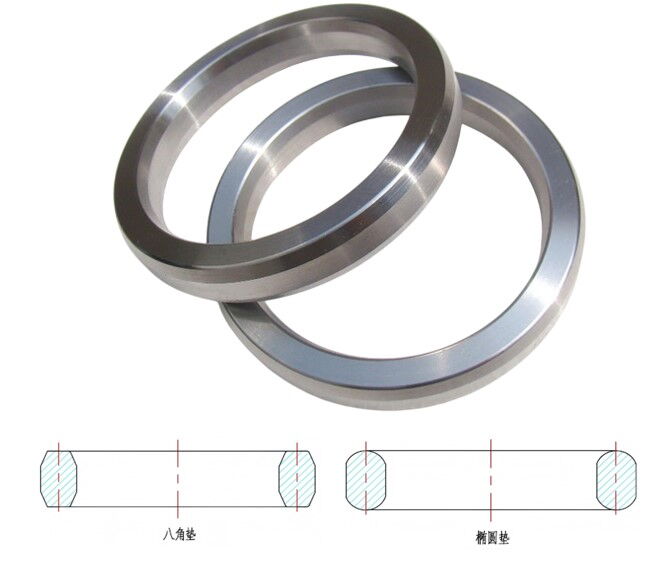

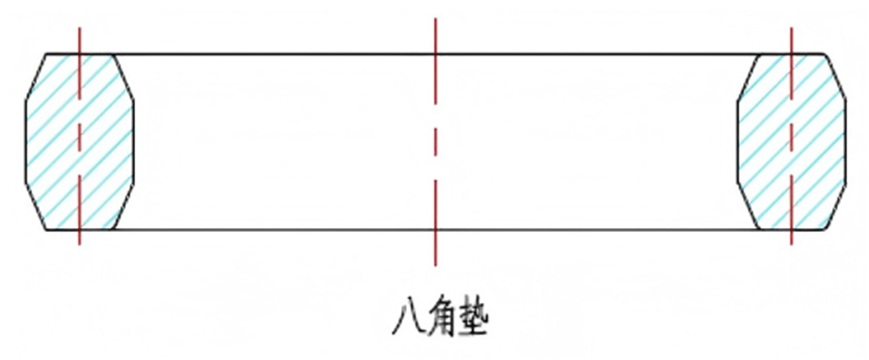

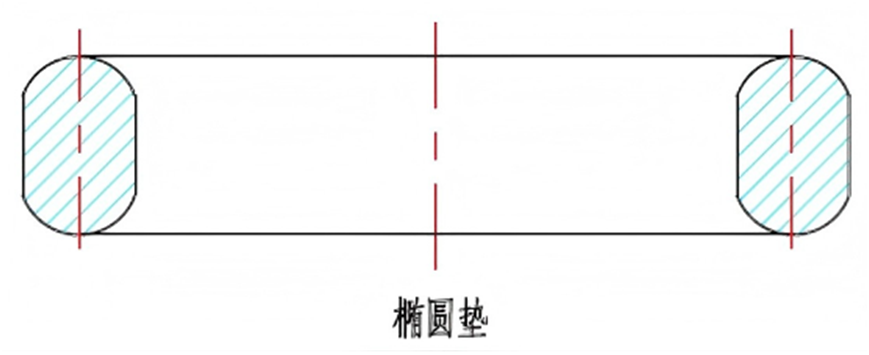

Metallic ring gaskets play a critical role in high-temperature and high-pressure environments. Typically machined from solid metal, these gaskets feature octagonal or oval cross-sectional shapes, which provide superior sealing performance due to their geometric design.

The cross-section of metallic ring gaskets is a core factor in their sealing efficacy. The octagonal or oval profile allows the gasket to form close contact with both the inner and outer trapezoidal surfaces of the flange groove, especially the outer side. When compressed, this structure generates a radial self-tightening sealing effect, meaning that under internal media pressure, the seal tightens further, improving overall performance. This self-energizing characteristic makes metallic ring gaskets particularly suited to extreme conditions involving high temperatures and pressures.

Metallic ring gaskets are widely used in industries such as petrochemical processing and power generation, especially in pipeline connections and pressure vessel sealing. In these demanding environments, the gaskets withstand elevated temperature and pressure while maintaining reliable and stable sealing.

However, there are limitations to consider. Due to the inherent rigidity of metal, these gaskets lack effective resilience during thermal cycling, potentially compromising the seal. Additionally, uneven deformation between the gasket and flange components may occur, increasing the risk of leakage.

Proper installation and maintenance are critical when using metallic ring gaskets. After each disassembly, the flange sealing surface must be carefully treated before reassembly. This includes:

Cleaning the sealing surface

Inspecting for flatness and surface integrity

Following these best practices not only ensures optimal sealing but also extends the service life of both the gasket and the flange.

Metallic ring gaskets remain the preferred sealing solution in high-temperature, high-pressure environments due to their thermal resistance, pressure endurance, and self-tightening seal characteristics. Despite their limitations, they deliver trustworthy performance under the most demanding conditions and are an indispensable component in critical sealing applications.

For low-emission sealing challenges, Magpie Sealing offers proven solutions. If you have technical questions or want to explore more about sealing technologies, follow us, leave a comment, or get in touch. We welcome your inquiries and discussions!

Stay tuned for our next issue as we continue our series on sealing gasket types. See you next time!