Magpie Sealing Technology Insights

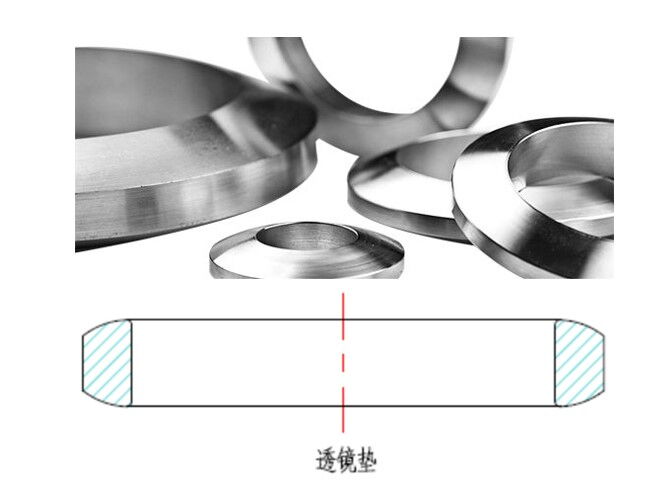

Flanges and Gaskets — Sealing Gasket Forms (Part 13): An Introduction to Metal Lens Gaskets

Are you familiar with the critical components in industrial sealing systems? One such essential component is the metal lens gasket, a specialized sealing element that plays a key role in achieving precise "engagement" between equipment, ensuring reliable sealing performance. In this article, let's delve into the structure, working principle, and application considerations of metal lens gaskets.

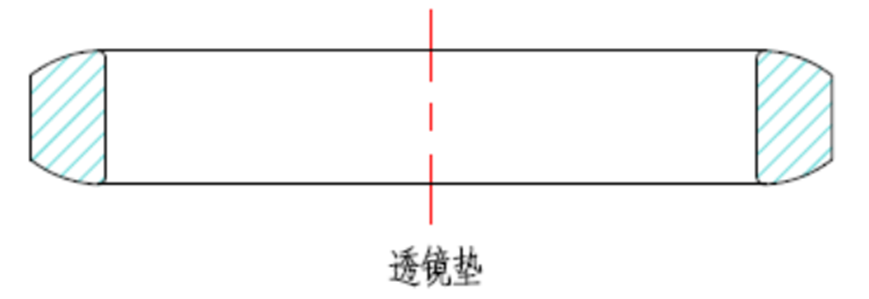

A metal lens gasket features a spherical sealing surface, which mates with a conical sealing face on the pipeline, forming a line contact seal. This design embodies the precision of mechanical sealing principles.

The spherical-conical interface offers a key advantage: when preload is applied during installation, the contact area undergoes plastic deformation, creating a tight sealing line. This deformation not only enhances the sealing performance but also provides some tolerance for installation misalignment.

However, this plastic deformation leads to a unique fit between the gasket and sealing surface, which limits the interchangeability of components. Each gasket-sealing face pair becomes essentially customized through deformation.

Metal lens gaskets are predominantly used in high-pressure piping systems, particularly in critical connections within petrochemical and power industries. Their robust sealing capability allows them to withstand extreme pressures, ensuring the safety and integrity of complex industrial processes.

Despite their advantages, the sealing surface, being a contact between a sphere and a cone, can develop indentations over long-term service, which may affect sealing reliability and limit reusability.

Due to the forced sealing nature of the design, precise control of preload force is essential:

Excessive preload can cause over-deformation, compromising the sealing integrity.

Insufficient preload may fail to establish a proper seal.

Fortunately, the metal lens gasket exhibits good self-centering, which simplifies alignment during installation. Still, installation should always be performed by qualified professionals to ensure proper sealing.

When selecting and using metal lens gaskets, it's crucial to evaluate:

Operating pressure and temperature range

Medium compatibility

Material compatibility with pipeline components

Installation and maintenance procedures

Correct gasket selection and standardized installation are key to long-term sealing reliability.

At Magpie Sealing, we focus on delivering low-emission sealing solutions. If you have any questions about sealing technologies, we welcome you to follow us, leave your comments, or consult with us directly.

Thank you for reading! Stay tuned for the next installment in our series on sealing gasket types. See you next time!