Magpie Sealing Technology Insights

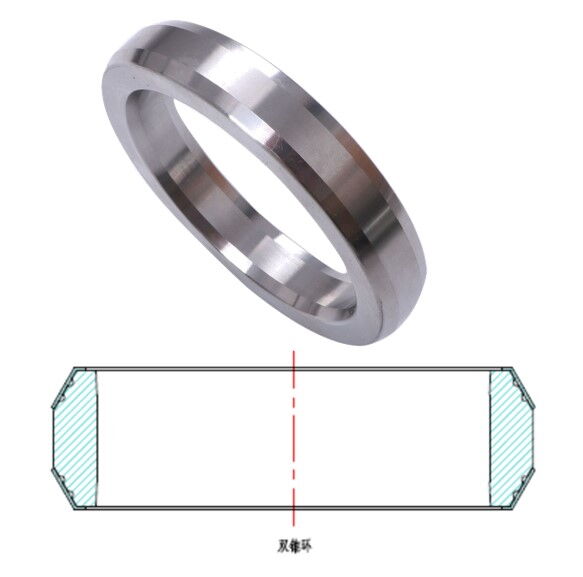

Flanges and Gaskets — Sealing Gasket Types (Part 14): Metal Double-Cone Ring Gaskets in Industrial Sealing

In the field of industrial sealing, metal double-cone ring gaskets play a vital role. But how exactly do they function to ensure reliable sealing performance between equipment components? Let's explore this in detail.

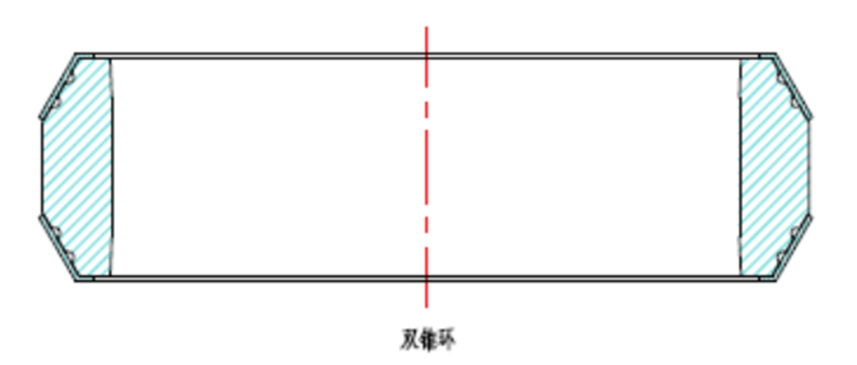

A metal double-cone ring gasket is a high-pressure sealing element characterized by its radial self-tightening structure. The sealing component consists of a metallic ring with double-cone surfaces, typically machined from medium-strength carbon steel or stainless steel. These conical surfaces, angled at 30 degrees, are coated with a soft metal layer approximately 1 mm thick, commonly made from annealed aluminum, annealed copper, or stainless steel.

This soft metal overlay ensures a tight, conforming seal while preventing potential damage from metal-to-metal contact between hard surfaces. The double-cone ring is usually affixed to the end cap using a support bracket or bolts. Its inner surface is designed to maintain a proper clearance with the end cap, allowing enough space for elastic rebound under pressure and maintaining structural stability.

Upon tightening, the double-cone ring fits closely against the end cap. As system pressure increases, the end cap undergoes slight displacement. Leveraging both its own elasticity and the radial expansion induced by pressure, the double-cone ring achieves a self-tightening seal. This mechanism automatically intensifies the sealing stress in proportion to the internal pressure, ensuring a reliable seal under demanding conditions.

To achieve optimal performance with metal double-cone ring gaskets, the following considerations are essential:

Proper Clearance: Ensure a precise gap between the gasket and the end cap. This balance is crucial for allowing rebound while avoiding instability.

Material Selection: The choice of soft metal layer must account for the working medium's corrosiveness and operating temperature.

Standardized Installation: Follow strict installation protocols to guarantee correct component alignment and effective sealing.

Thanks to its radial self-sealing design, the metal double-cone ring gasket excels in high-pressure applications. With appropriate material selection, precise clearance control, and standardized installation, it delivers long-term, stable sealing performance. As such, it is widely adopted in high-pressure sealing systems.

At Magpie Sealing, we continue to focus on solving low-emission sealing challenges. If you have any questions about sealing technologies, feel free to follow us, consult with our team, or leave your comments. Thank you for reading. Stay tuned for the next installment on sealing gasket types!