Magpie Sealing Technology Insights

Flanges and Gaskets – Sealing Gasket Forms: Types of Metal Spiral Wound Gaskets

Today, we continue our discussion on gasket types with a focus on semi-metallic gaskets, which are composite gaskets made from both metallic and non-metallic materials.

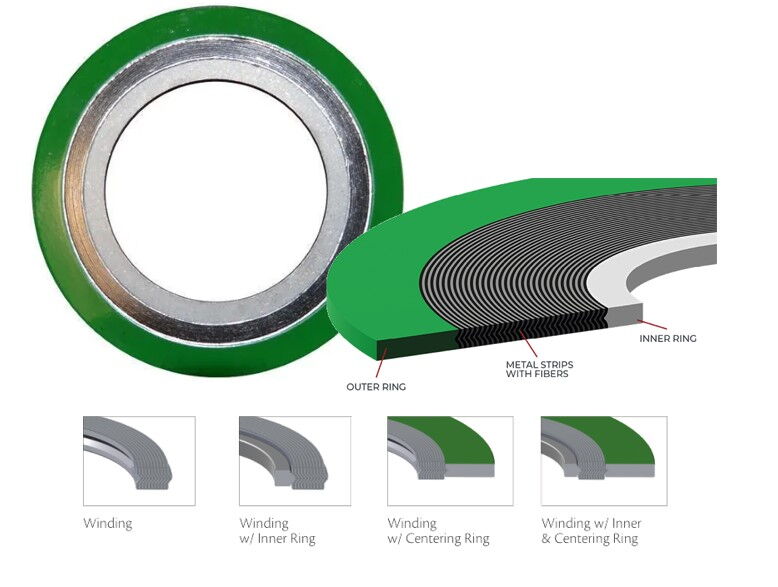

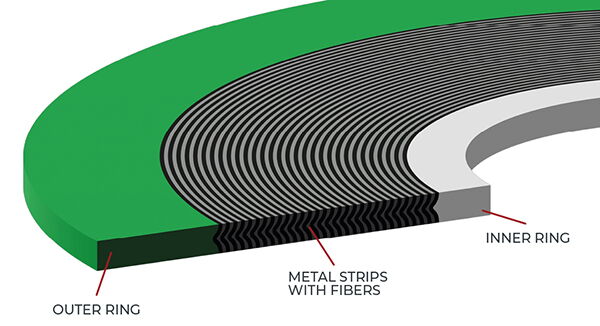

A typical example of semi-metallic gaskets is the spiral wound gasket. This type of gasket is constructed by spirally winding a specially formed metal strip (with a V-shaped or W-shaped cross-section) together with a non-metallic filler material. The result is a composite gasket that offers excellent resilience and outstanding sealing performance.

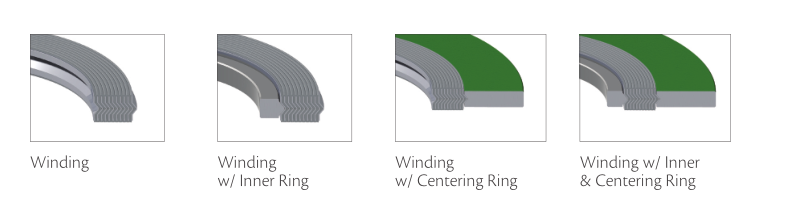

Spiral wound gaskets are available in several structural types, each tailored to specific application needs:

A simple design without inner or outer rings. Suitable for flanges with a precise sealing surface and uniform pressure distribution.

This variant adds an inner ring to the basic structure, enhancing the gasket's structural integrity. The inner ring helps the gasket maintain shape under pressure and prevents inward buckling.

This type features an outer ring, which improves installation stability and reinforces sealing performance, especially under fluctuating loads.

Incorporating both inner and outer rings, this gasket offers optimal stability and superior sealing. It is ideal for applications demanding extremely high sealing reliability, making it a top choice in critical industrial settings.

Due to their exceptional performance characteristics, spiral wound gaskets are among the most widely used sealing gaskets across industrial sectors. They are especially valuable in industries such as chemical processing, oil refining, metallurgy, energy production, and nuclear power.

Designed for medium to low temperatures and medium to high pressures, these gaskets provide stable and reliable sealing for various equipment and pipeline flanges. Whether in harsh industrial environments or in applications requiring ultra-tight seals, spiral wound gaskets prove to be a key component in preventing leaks, ensuring safety, and maintaining operational efficiency.

At Magpie Sealing, we specialize in low-leakage sealing technologies. If you have any questions regarding sealing solutions or gasket selection, feel free to follow us, reach out, or leave a comment. Thank you for reading!

Stay tuned for our next installment, where we’ll continue exploring more gasket types. See you next time!