Magpie Sealing Technology Insights

Flanges and Gaskets – Forms of Sealing Gaskets (Part 6): An Introduction to Metal Jacketed Gaskets

In this article, we focus on metal jacketed gaskets, a type of semi-metallic gasket widely used in industrial sealing applications.

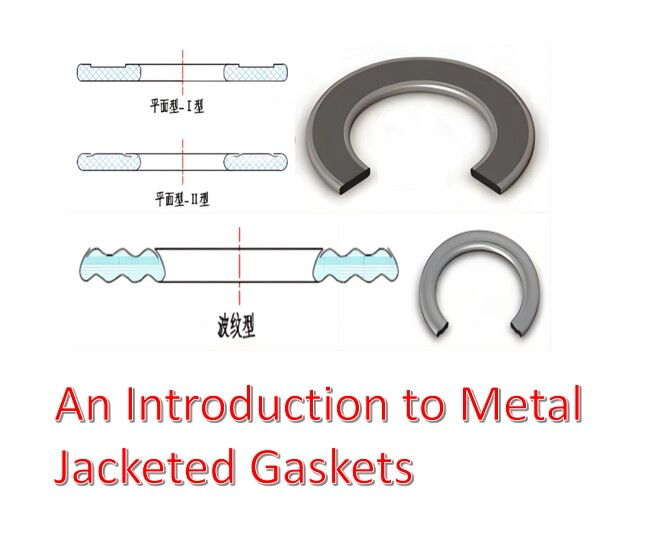

Metal jacketed gaskets are composite gaskets formed by enclosing a soft, non-metallic filler material—such as flexible graphite, non-asbestos rubber sheets, or ceramic fiber—within a thin metal sheath using specialized cold-forming techniques. Depending on their cross-sectional design, these gaskets are commonly classified into:

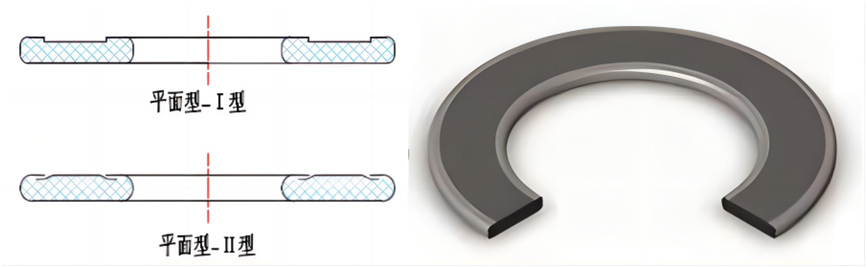

- Flat metal jacketed gaskets

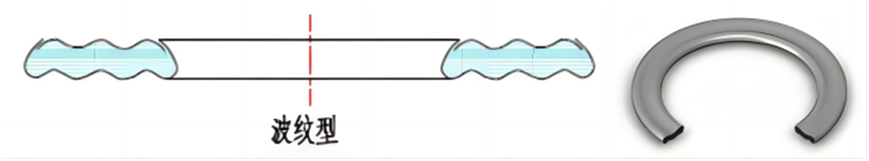

- Corrugated metal jacketed gaskets

Flat jacketed gaskets are ideal for applications where the sealing surfaces are smooth and even—such as flange joints and piping connections. The flat cross-section ensures tight conformity between the gasket and the sealing surface, effectively preventing leakage.

Corrugated jacketed gaskets are better suited for sealing surfaces with slight irregularities or where greater compressibility is required. The corrugated design enhances elasticity, allowing the gasket to better fill micro-gaps under pressure, thereby improving overall sealing performance.

Whether flat or corrugated, metal jacketed gaskets offer reliable sealing solutions for a wide range of demands. Due to their unique structure and excellent sealing characteristics, they are widely used in:

- Heat exchangers

- Pressure vessels

- Pumps

- Valves

- Flanged connections

To further enhance sealing performance, the surface of metal jacketed gaskets may be laminated with soft sealing materials such as flexible graphite or PTFE. This design allows the gasket to maintain sealing tightness while significantly reducing required sealing stress. As a result, reliability increases, and equipment service life is extended.

Metal jacketed gaskets combine cost-effectiveness and sealing performance, making them a valuable solution in industrial sealing. Their distinctive structural design and broad applicability give them a vital role across various industries.

If you have questions about sealing technology, feel free to follow Magpie Sealing, leave a comment, or reach out for consultation.

Stay tuned for our next article in the gasket series. See you next time!