Magpie Sealing Technology Insights

Flanges and Gaskets – Forms of Sealing Gaskets (Part 7): Introduction to Metal Corrugated Composite Gaskets

In this article, we continue our discussion on sealing gasket types, turning our attention to the metal corrugated composite gasket, a highly effective and adaptable solution for challenging sealing applications.

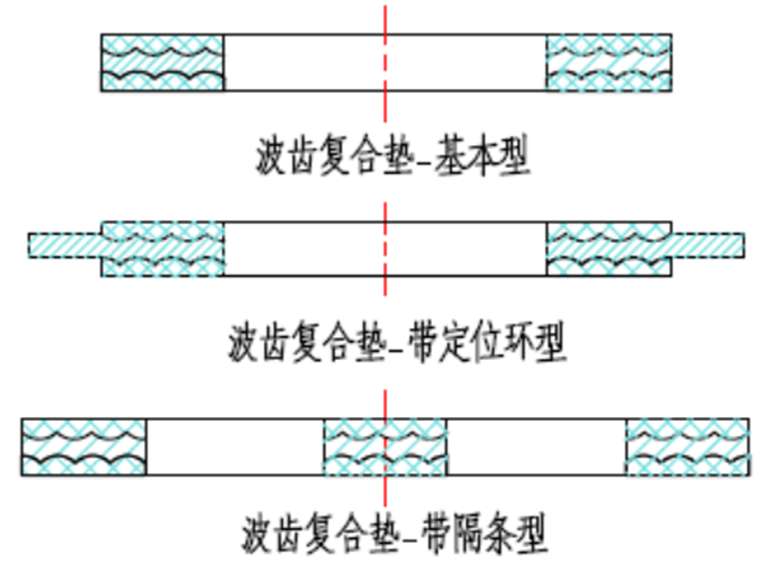

The metal corrugated composite gasket is constructed by machining a series of concentric, wave-shaped grooves onto both faces of a flat metal core. These grooves form a corrugated tooth structure, with the peaks on each side intentionally offset from one another. This clever design significantly enhances the gasket's compressibility and resilience, allowing it to conform more effectively to uneven sealing surfaces and deliver superior sealing performance under pressure.

The sealing interface typically features concentric line contact, a design that mimics labyrinth-style sealing. This structure creates multiple sealing barriers along the contact lines, helping to effectively prevent media leakage. These gaskets can bond tightly to a sealing layer or be applied directly to a sealing surface, achieving excellent sealing reliability in either case.

To adapt to various media and working conditions, the gasket surfaces can be laminated with different materials, such as:

- Flexible graphite

- PTFE (Polytetrafluoroethylene)

- Non-asbestos sheet

- Soft metals

These layers further enhance sealing performance by improving chemical resistance, adaptability, and longevity.

One of the standout features of metal corrugated composite gaskets is their ability to achieve excellent sealing without requiring excessive bolt load. Thanks to their corrugated structure, they offer high elasticity and adaptability, making them effective even under relatively low compressive forces.

This characteristic not only simplifies installation but also reduces the risk of damage to sealing surfaces, ultimately extending the service life of equipment.

The metal corrugated composite gasket represents a sophisticated combination of structural design and material science. Its labyrinth-style sealing effect, excellent resilience, and compatibility with various cover materials make it an ideal choice for demanding industrial sealing environments.

If you have questions about sealing technologies, feel free to follow Magpie Sealing, leave your comments, or get in touch for technical support.

We'll continue exploring gasket types in the next installment. See you then!