Magpie Sealing Technology Insights

Flanges and Gaskets – Forms of Sealing Gaskets (Part 8): Understanding Metal Toothed Composite Gaskets

In the field of industrial sealing, metal toothed composite gaskets have gained significant attention due to their unique structural design and excellent performance. Today, we explore their key features and application advantages.

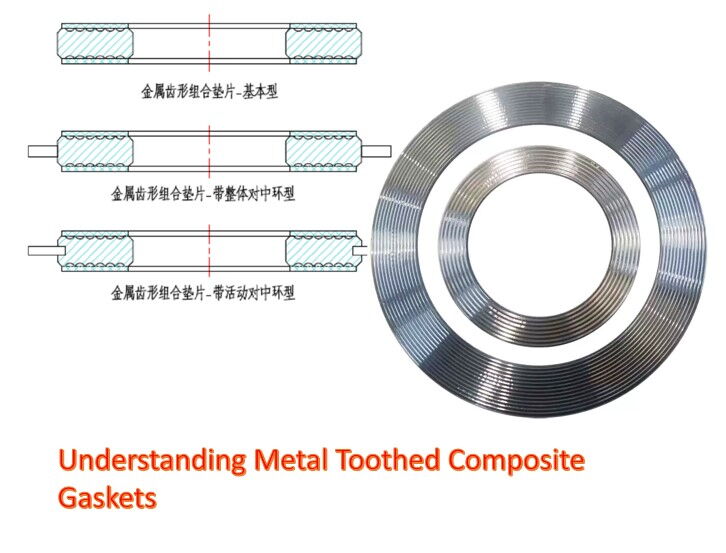

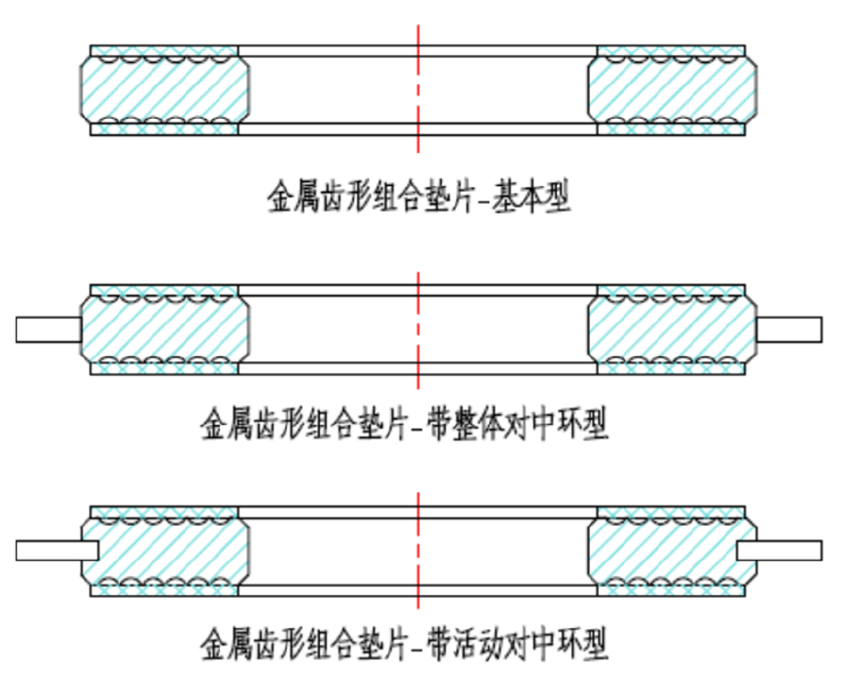

Metal toothed composite gaskets are widely used in flange connections across various industrial equipment. These gaskets combine the strength of metal with the sealing properties of soft materials, offering a highly reliable sealing solution.

Structurally, both sides of the metal core are machined with concentric, wave-like serrations forming a 90-degree V-shaped angle. This groove design not only enhances elasticity but also creates a labyrinth-style sealing path, improving sealing effectiveness.

Upon compression, these serrated grooves form multiple sealing barriers, effectively preventing media leakage even under challenging conditions.

To optimize sealing performance, the gasket surfaces can be covered with various materials depending on the application environment, including:

- Flexible graphite

- PTFE (Polytetrafluoroethylene)

- Non-asbestos rubber sheets

These coverings serve dual purposes: enhancing the gasket's adaptability and preventing direct metal-to-metal contact, thus protecting the flange surface from damage.

When selecting and using metal toothed composite gaskets, factors such as:

- Temperature

- Pressure

- Medium characteristics

must be carefully evaluated. Proper gasket selection and installation ensure long-term reliable sealing, while regular inspection and maintenance are essential to sustaining performance.

Metal toothed composite gaskets offer a perfect balance of durability, resilience, and sealing efficiency. Their advanced design and material compatibility make them a trusted choice in critical industrial applications.

For more insights into sealing technologies, follow Magpie Sealing, leave a comment, or contact us for support.

Stay tuned for the next part in our gasket series. See you soon!