Magpie Sealing Technology Insights

Flanges and Gaskets – Forms of Sealing Gaskets (Part 9): Characteristics and Application value of Metal Corrugated Composite Gaskets

Today, let's delve into the characteristics and application value of metal corrugated composite gaskets. If you're particularly interested in any aspect of their features or usage scenarios, feel free to leave a comment below for discussion.

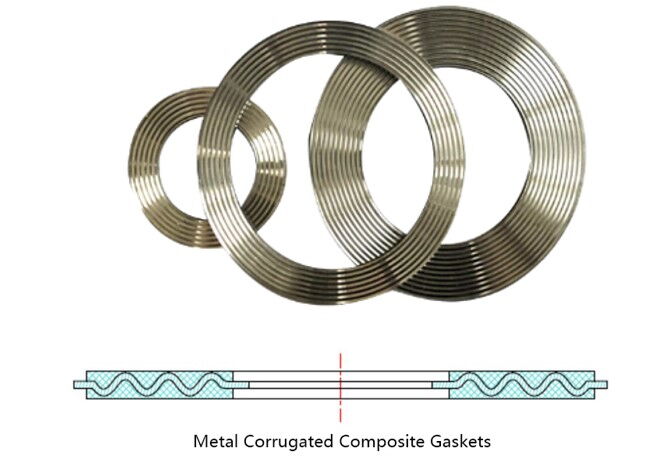

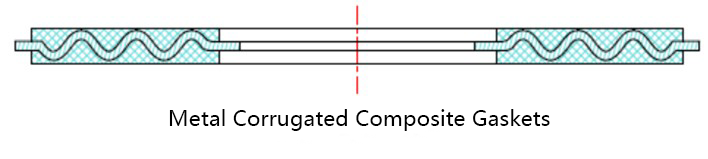

A metal corrugated composite gasket consists of a metallic foil sheet shaped into regular and evenly spaced concentric corrugations. Structurally, its wavy design strikes a smart balance between rigidity and flexibility. When compressed, the corrugated profile deforms uniformly, which helps to distribute stress evenly and significantly enhances sealing reliability.

Depending on the specific application requirements, these gaskets can be constructed using either a single-layer or double-layer metallic sheet. In the double-layer design, the outer ring is typically welded shut, while the inner ring remains open. This configuration creates a self-tightening effect, further improving the sealing performance.

Metal corrugated gaskets also offer great adaptability in terms of material selection. To accommodate various media properties and operating conditions, different sealing layers can be bonded to the metal surface.

Common composite materials include:

- Flexible graphite

- PTFE (polytetrafluoroethylene)

- Non-asbestos sheets

These materials not only enhance the sealing effect but also protect the metallic core, thus extending the service life of the gasket.

In practical applications, metal corrugated composite gaskets are especially suitable for environments with significant pressure fluctuations or temperature variations. Their excellent resilience allows them to compensate for flange gap changes caused by thermal expansion or mechanical vibration, thereby ensuring long-lasting, reliable sealing.

Moreover, their thoughtful structural design simplifies installation, reduces assembly complexity, and improves overall work efficiency.

At Magpie Sealing, we specialize in solving low-emission sealing challenges. If you have any questions or need insights into sealing technologies, be sure to follow us. We welcome your messages, consultations, and comments!

Thank you for reading. Stay tuned for our next installment on sealing gasket types. See you next time!