In industrial piping and equipment connections, flanged joints are indispensable components. They ensure the safe transfer of fluids within the system, prevent leaks, and guarantee the stable operation of the entire system. Today, we will delve into two primary design concepts for flanged joints: the Floating-Type Flanged Joint with non-metallic to metallic contact (FLT) and the Metallic-to-Metallic Flanged Joint (MMC). These two concepts differ significantly in sealing principles, application scenarios, and performance characteristics. Understanding them can help us make more appropriate choices in practical engineering.

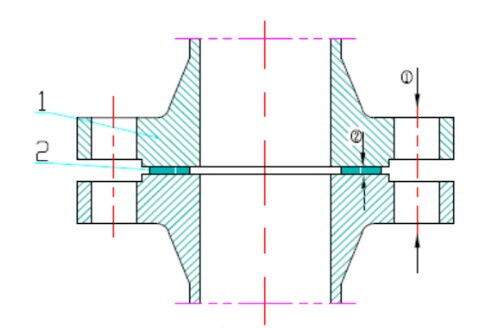

Among the various design concepts for flanged joints, the Floating-Type Flanged Joint with non-metallic to metallic contact (FLT) is a widely used type with a unique sealing principle. It achieves sealing through the elastoplastic deformation of the gasket. To put it vividly, the flange is like sitting on a "spring," and this design holds an important position in the traditional sealing field.

The non-metallic to metallic sealing concept, also known as the Elastomeric Concept, is a traditional sealing design. In this design, the bolt load acts on the sealing contact surface between the flange and the gasket. To put it vividly, the flange is like sitting on a "spring." The core of this design lies in the elastoplastic deformation of the gasket when it is compressed.

This deformation serves two important functions:

Compensating for Defects: There may be various macroscopic and microscopic defects between the gasket and the flange contact surface. Elastoplastic deformation can effectively fill these defects, ensuring the integrity of the sealing surface.

Enhancing Sealing: Through deformation, the tightness of the gasket itself is improved. Moreover, under such elastoplastic deformation, the sealing stress between the contact surfaces can effectively exceed the pressure of the fluid being sealed, thereby preventing the fluid from leaking through the flange sealing surface and the gasket itself.

In the non-metallic to metallic sealing design, the focus is on improving and perfecting the elastoplastic deformation capability of the gasket, as well as its resistance to creep stress relaxation and fatigue failure, by enhancing the performance of the sealing material and the structure of the gasket. These improvements can maximize the reduction or compensation for the loss of sealing stress.

This type of joint is widely used in various industrial scenarios. However, the gasket stress changes significantly from installation to operation and during operation. For example:

Installation Load: The installation load must be sufficient to resist the thrust of the medium. This load acts entirely on the sealing surface before the medium pressure is generated. If the medium pressure is high enough, there is a risk of the gasket being crushed.

Environmental Factors: The effects of the medium's temperature, pressure, and chemical properties on the gasket must also be considered. For instance, in high-temperature environments, the gasket may experience creep or aging, leading to a decline in sealing performance. In high-pressure environments, the gasket may be crushed or extruded. Corrosive media can erode the gasket material, reducing its service life.

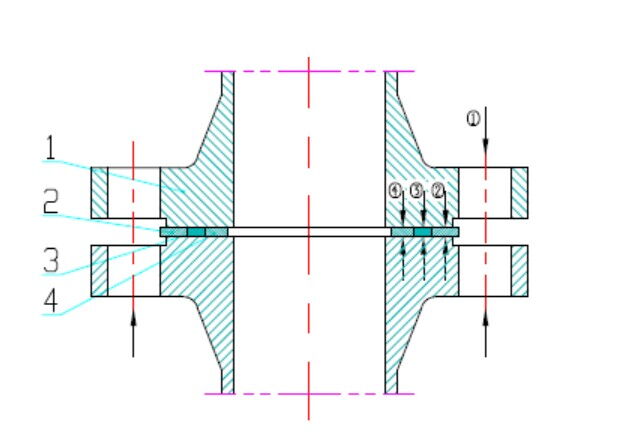

Unlike the non-metal-to-metal floating flange joint (FLT), the metal-to-metal flange joint (MMC) adopts a more advanced design concept. This joint achieves constant sealing stress through direct metal-to-metal contact, combined with the use of a limiting ring, thereby maintaining excellent sealing performance under various complex working conditions.

The metallic-to-metallic sealing concept, also known as the Constant Stress Gasket concept, is a revolutionary design approach. The core of this design is to ensure that the sealing working stress σgo remains greater than the medium pressure and stays within an effective numerical range or remains constant at a specific value throughout the service life of the seal, regardless of any factors that may cause the loss of sealing working stress.

During installation, the gasket is equipped with a limiting ring to ensure direct contact between the flange metal surfaces (such as raised face or tongue-and-groove flanges) or between the gasket limiting ring metal surface and the flange. The bolt load acts on the sealing surface and the metal limiting ring through the flange face, thereby ensuring the constancy of the sealing working stress during the service life of the seal.

This sealing structure has several significant advantages:

Constant Sealing Stress: The design of the metal limiting ring ensures that the sealing working stress remains constant throughout the service life of the seal, unaffected by changes in medium pressure, temperature, or other factors.

Increased Stiffness: The full contact between the flange metal and the metal limiting ring of the gasket restricts the flange's rigid deformation, enhancing the stiffness of the entire joint.

Reduced Sensitivity: The sensitivity of the sealing joint to external bending moments, temperature, and pressure changes is greatly reduced, improving the stability and reliability of the system.

Metallic-to-metallic flanged joints are suitable for scenarios where extremely high sealing performance is required, especially in harsh environments such as high temperature, high pressure, and corrosive media. This design can effectively avoid common problems of traditional non-metallic to metallic sealing joints in these environments, such as gasket creep, aging, crushing, and extrusion.

Unlike the Floating-Type Flanged Joint with non-metallic to metallic contact (FLT), the Metallic-to-Metallic Flanged Joint (MMC) adopts a more advanced design concept. This joint achieves constant sealing stress through direct metal-to-metal contact and the use of limiting rings, thereby maintaining excellent sealing performance in various complex operating conditions.

FLT: Relies on the elastoplastic deformation of the gasket to achieve sealing. The sealing stress changes significantly during operation and requires regular inspection and maintenance.

MMC: Ensures constant sealing stress through the metal limiting ring, providing more stable sealing performance suitable for long-term operation.

FLT: Is more sensitive to temperature, pressure, and the chemical nature of the medium. Appropriate gasket materials must be selected based on specific operating conditions.

MMC: Has stronger adaptability to harsh environments and can effectively resist the effects of high temperature, high pressure, and corrosive media.

FLT: Installation and maintenance are relatively simple, but regular inspection of the gasket's condition is required. The cost of replacement is relatively low.

MMC: Installation requirements are higher, with precise control of bolt load and machining accuracy of metal contact surfaces needed. However, the long-term operating cost is lower, with fewer maintenance needs.

After understanding the design concepts and performance characteristics of the two types of flanged joints, let's look at some practical application cases. These cases will help us better understand the performance and applicability of FLT and MMC in different industrial scenarios.

In the chemical industry, piping systems often need to handle high-temperature, high-pressure, and corrosive media. For example, at a chemical plant, the outlet piping of a reactor used a Metallic-to-Metallic Flanged Joint (MMC) and successfully solved the problem of gasket aging and leakage that occurred with traditional non-metallic to metallic joints (FLT) in high-temperature and high-pressure environments. This significantly improved the safety and reliability of the system.

In the oil and gas industry, the sealing performance of the piping system directly affects production safety and efficiency. A natural gas transmission pipeline used a Floating-Type Flanged Joint (FLT), but the gasket extruded under high pressure, causing leakage. After assessment, the system was converted to a Metallic-to-Metallic Flanged Joint (MMC), effectively solving the problem and enhancing the system's stability and safety.

Flanged joints are essential components in industrial systems, and their sealing performance directly affects the safety and efficiency of the system. The Floating-Type Flanged Joint with non-metallic to metallic contact (FLT) and the Metallic-to-Metallic Flanged Joint (MMC) are two major design concepts, each with its own advantages and disadvantages. When selecting a flanged joint, it is necessary to consider the specific operating conditions and requirements, taking into account factors such as sealing performance, environmental adaptability, and maintenance costs. It is hoped that the introduction in this article will help everyone better understand and select the appropriate flanged joint to ensure the safe operation of industrial systems.