(API 624 Additional High Temperature Version)

Key Specifications / Features

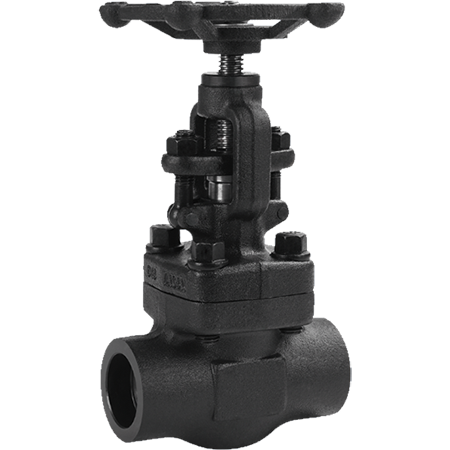

Our Factory produces high-performance check valves in compliance with API 602 standards. These valves are forged from stainless steel ASTM A182 F316, ensuring exceptional corrosion resistance and durability. With a 1/2 inch (DN15) size and a pressure rating of Class 800 LB (PN130), they are designed for low emission and feature a bolted bonnet for enhanced safety and reliability. The welded ends provide secure and efficient connections. These check valves are ideal for applications requiring minimal leakage and robust performance.

- Model No.: MV-20250402-FSCV-04

- Hits: 18

- Categories: Forged Steel Check Valve

- Tags: API 602 Check Valve, ASTM A182 F316 Check Valve, 1/2 Inch Check Valve

Detail Information

Product Name: ASTM A182 F316 Check Valve

Design Standard: API 602

Body Material: ASTM A182 F316

Size: 1/2 Inch, DN15

Pressure: Class 800 LB, PN130

End: Welded

Feature: Bolted Bonnet

Product Range

Size: NPS 1/2-6 Inch (DN15-DN150)

Pressure Rating: Class 150-2500 LB, PN20-PN420

Bonnet Type: Bolted Bonnet (BB), Welded Bonnet (WB)

Features: Swing Type, Lift Type (Piston), Ball Type

Body Material: ASTM A105, A350 LF2, A182 F11, F22, F91, F304/304L, F316/316L, F321, F347, F51, Monel, Inconel, etc.

Applicable Standards

Design: API 602, ISO 15761, ASME B16.34

Inspection & Testing: API 598

Marking: MSS SP-25

P/T Rating: ASME B16.34

Face to Face: ASME B16.10

End to End: Manufacturer Standard or ASME B16.10

Socket Welding: ASME B16.11

Screwed Ends: ASME B1.20.1

Flanged: ASME B16.5

Butt Welding: ASME B16.25

The packing used in forged valves is the M800 series graphite packing,

with a graphite carbon content exceeding 99% and a sulfur content below 50 PPM.

The dynamic leakage rate, as tested according to API 622, is less than 12 PPM.

The static leakage rate is below 6 PPM.

All the gaskets used are low-emission gaskets certified by TÜV Rheinland TA-LUFT.

Type Test Report for 2-Inch Gate Valve

According to ISO 15848-1 at 400°C

Type Test Report for 1-Inch Globe Valve

According to ISO 15848-1 at 400°C

Type Test Report for 3/4-Inch Gate Valve

According to ISO 15848-1 at 400°C

The 0.5-inch forged steel gate valve in accordance with API 602 is tested for an ISO 15848-2 Class A leakage rate below 50 PPMV, using the M600 model low emission packing.

The 1-inch forged steel gate valve, in accordance with API 602, is tested for an ISO 15848-2 Class A leakage rate of less than 50 PPMV, using the M600 model low-emission packing.

The 1.5-inch forged steel globe valve, in accordance with API 602, is tested for an ISO 15848-2 Class A leakage rate of less than 50 PPMV, using the M800 model low-emission packing.

The API 624 test for a 2-inch forged steel gate valve in accordance with API 602 uses the M600 model low-emission packing.

Similar Products

ASTM A182 F316L Check Valve, API 602, ASME B16.34, 1/2 Inch

API 602 Lift Check Valve, ASTM A105N, 1-1/2 Inch, 800 LB, BB

Y Pattern Check Valve, API 602, ISO 15761, ASTM A105N, 1 IN