(API 624 Additional High Temperature Version)

Key Specifications / Features

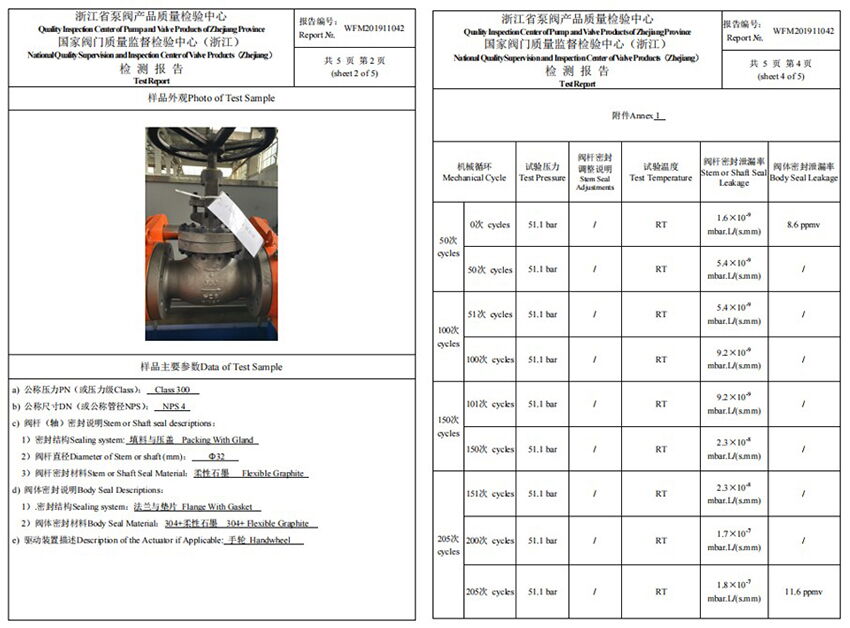

The ASTM A217 C12 Angle Globe Valve is a high-quality valve designed to meet the stringent requirements of BS 1873. It features an alloy body and trim, ensuring durability and resistance to corrosion. The valve has a 4-inch diameter (DN100) and is rated for Class 300 LB and PN50 pressure, making it suitable for demanding applications. It comes with raised face (RF) flanged ends for secure connections and is operated by a handwheel, providing precise control. This valve is ideal for industries requiring robust and reliable fluid control solutions.

- Model No.: MV-20250626-CSGLV-03

- Hits: 5

- Categories: Cast Steel Globe Valve

- Tags: ASTM A217 C12 Globe Valve, Angle Globe Valve, 4 Inch Globe Valve

Detail Information

Product Name: ASTM A217 C12 Angle Globe Valve

Type: Angle Globe Valve

Design Standard: BS 1873

Body Material: ASTM A217 C12

Trim Material: ASTM A217 C12+STL

Size: 4 Inch, DN100

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Operation: Handwheel

Face to Face Standard: ASME B16.10

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Range

Body Materials:

Carbon Steel: ASTM A216 WCB, WCC, A352 LCB, LCC

Stainless Steel: ASTM A351 CF3, CF8, CF3M, CF8M

Alloy Steel: ASTM A217 WC6, WC9, C12

Gasket & Packing Material: Graphite, PTFE

Size Range: 2-24 Inch, DN50-DN600

Pressure Range: Class 150-2500 LB, PN16-PN420

End Connection: Flanged (RF, FF, RTJ)

Temperature Range: -29°C to 550°C

Medium: Water, Oil, Gas, Steam, etc

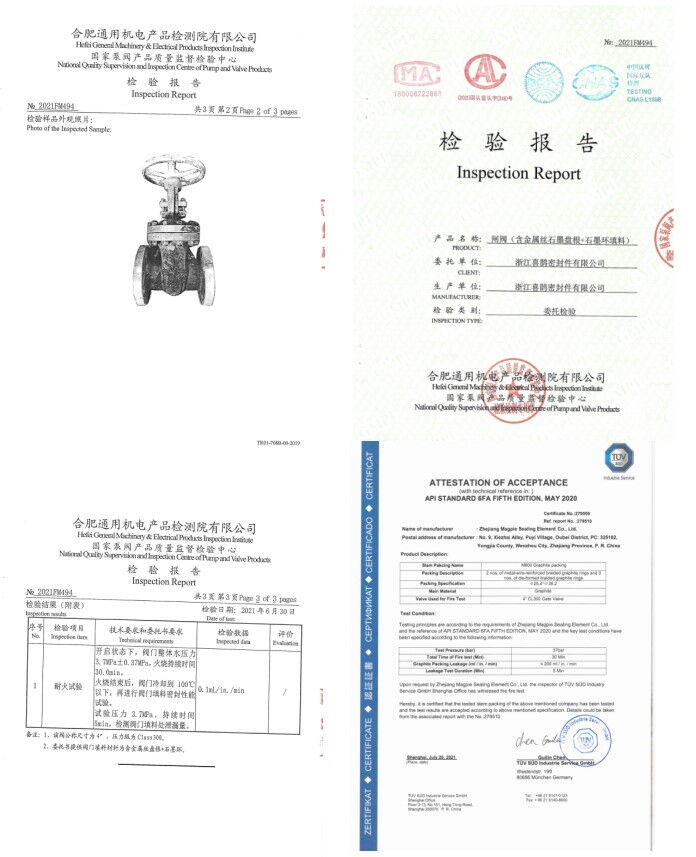

The packing used in cast steel valves is the M800 series graphite packing,

with a graphite carbon content exceeding 99% and a sulfur content below 50 PPM.

The dynamic leakage rate, as tested according to API 622, is less than 12 PPM.

The static leakage rate is below 6 PPM.

All the gaskets used are low-emission gaskets certified by TÜV Rheinland TA-LUFT

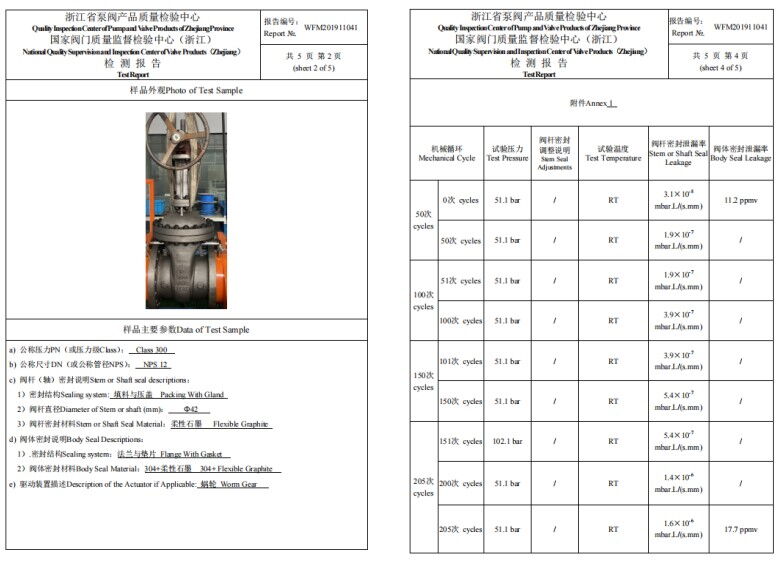

ISO 15848-1 Valve Tested Case Example: NPS4 Class 300 Valve

4-inch 300 LB Globe Valve: ISO 15848-1 Test at Ambient Temperature for 205 Cycles, High Leakage Rate of 1.8×10−7, Maximum Body Leakage at 11.6 PPMV

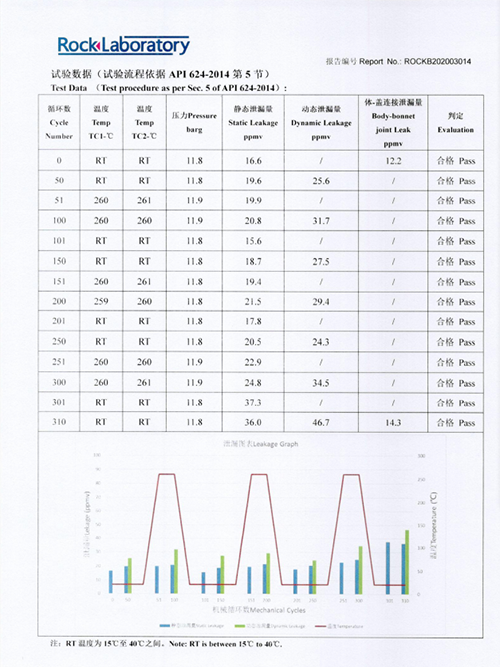

API 624 Valve Test Case 1: 12-inch 150 LB Gate Valve

12-inch 150 LB Gate Valve

API 624 Test

Maximum Packing Leakage: 46.7 PPMv

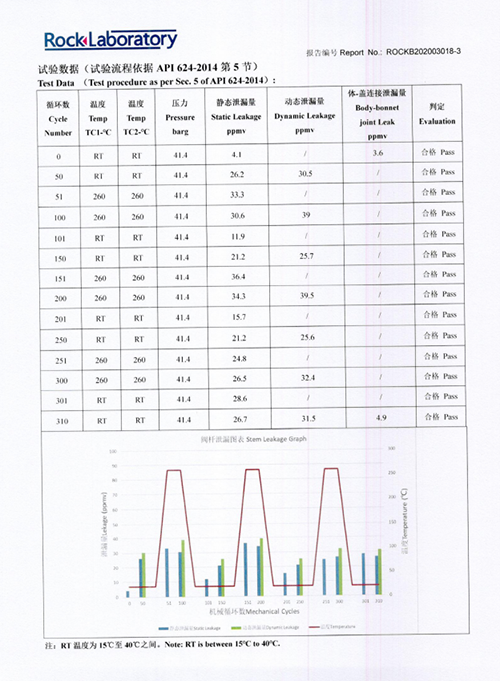

API 624 Valve Test Case 2: 12-inch 600 LB Gate Valve

12-inch 600 LB Gate Valve

API 624 Testing

Maximum packing leakage: 32 ppmv

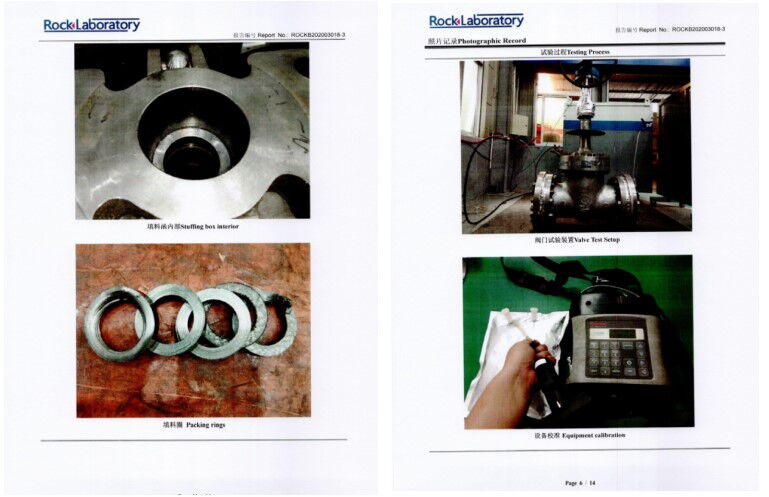

Fire Test Certification of Valve Packing

Fire Test Report and Certification for 4-inch Gate Valve with M800 Packing

ISO 15848-1 Valve Tested Case Example: NPS12 Class 300 Valve

12-inch 300 LB Gate Valve

ISO 15848-1 Test at Ambient Temperature for 205 Cycles

High Leakage Rate: 1.6×10−6

Maximum Body Leakage: 7.7 PPMV

The API 624 test for the API 600 WCB 12-inch 150 LB gate valve utilized an M600 low-emission graphite packing set.

The ISO 15848-2 Type A test for the API 600 WCB 2-inch 150 LB gate valve, which requires emissions below 50 PPMV, was conducted using an M600 low-emission graphite packing set.