(API 624 Additional High Temperature Version)

Key Specifications / Features

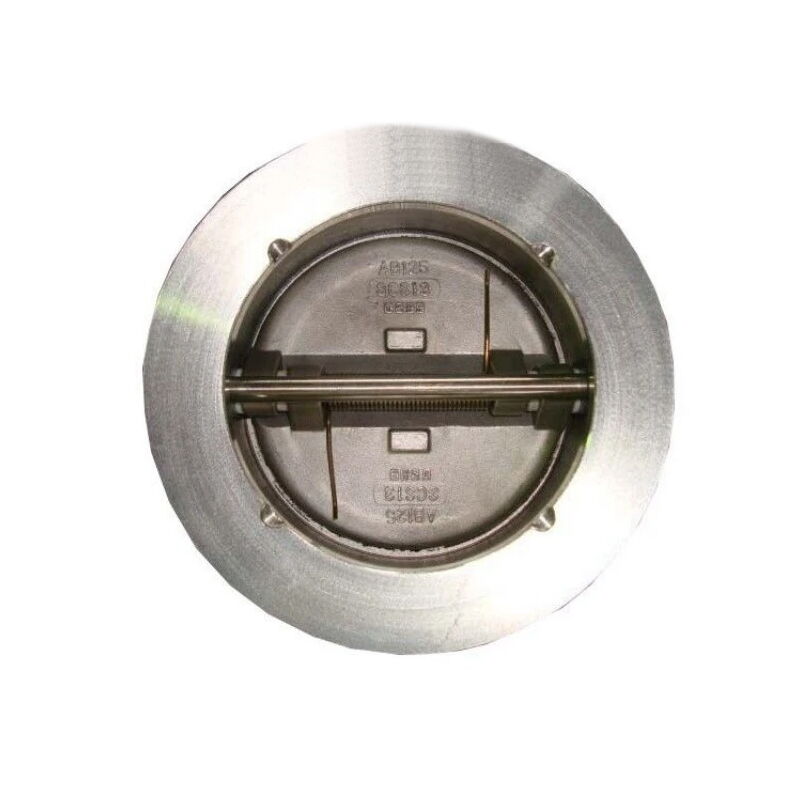

The Dual Plate Wafer Check Valve Plant offers a robust and reliable valve solution, meticulously designed in accordance with API 594 standards. This valve features an 8-inch (DN200) size and a pressure class of 300 LB, ensuring it can handle demanding industrial applications with ease. Constructed from ASTM A351 CF8 stainless steel, the valve body provides exceptional strength and corrosion resistance, making it suitable for a variety of environments. The wafer ends design allows for easy installation between flanges, facilitating seamless integration into existing systems.

- Model No.: MV-20250611-CSCV-09

- Hits: 17

- Categories: Cast Steel Check Valve

- Tags: ASTM A351 CF8 Check Valve, Wafer Check Valve, API 594 Check Valve

Detail Information

Product Name: Dual Plate Wafer Check Valve

Type: Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A351 CF8

Size: 8 Inch, DN200

Pressure: Class 300 LB, PN50

End Connection: Wafer

Face to Face Standard: API 594, MFG

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Range

Body Materials: Cast Carbon Steel, Stainless Steel, Alloy Steel, ect.

Gasket & Packing Material: Graphite/PTFE

Size Range: 2-20 Inch, DN50-DN500

Pressure Range: Class 150-2500 LB, PN16-PN420

End Connection: BW, Flanged

Temperature Range: -46°C to 325°C

Medium: Water, Oil & Gas

Key Features

Diverse Body Styles: Available in retainerless wafer, lug, flanged, hub end, butt-weld end, and thread end configurations to meet various installation needs.

API Certifications: Certified by the American Petroleum Institute (API) with API 594 and API 6D certificates, ensuring compliance with industry standards.

Fire-Safe Design: Inherently fire-safe due to the valve design, material, and construction. Both resilient seats and metal seat valves offer metal-to-metal sealing performance in case of fire.

Cost-Effective Installation: Lightweight and compact design with minimal space requirements, reducing installation costs. The compact design minimizes the distance between flanges and allows for easy installation between all flanges.