(API 624 Additional High Temperature Version)

Key Specifications / Features

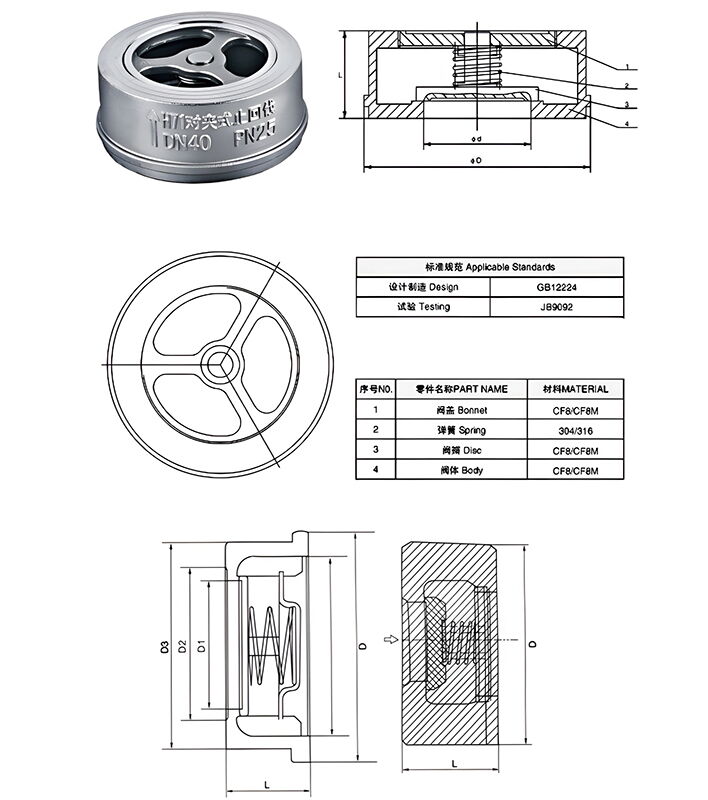

The ASTM A351 CF8 Check Valve Supplier offers a high-performance wafer check valve designed in compliance with API 594 standards. This valve features a cast stainless steel body (CF8), providing excellent corrosion resistance and durability. With a DN65 (2-1/2 inch) size and a pressure rating of PN25, it is classified at 300 LB, ensuring reliable performance in demanding applications. The wafer design allows for easy installation and space-saving integration into piping systems. This check valve is ideal for industries requiring robust flow control and long-term reliability.

- Model No.: MV-20250630-CSCV-03

- Hits: 18

- Categories: Cast Steel Check Valve

- Tags: API 594 Check Valve, Wafer Check Valve, ASTM A351 CF8 Check Valve

Detail Information

Product Name: ASTM A351 CF8 Wafer Check Valve

Type: Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A351 CF8

Size: DN65, 2-1/2 Inch

Pressure: PN25, Class 300 LB

End Connection: Wafer

Face to Face Standard: ASME B16.10

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Range

Material: ASTM A216 WCB, ASTM A351 CF8, CF8M

Nominal Diameter: DN15-DN300, 1/2-12 Inch

Nominal Pressure: PN16-PN100, Class 150-600 LB

Suitable Temperature: 0 to 200°C

Suitable Medium: Water, Oil, Steam, etc.

Wafer Check Valve Main Dimensions and Weight

|

Nominal Pressure PN (MPa) |

Nominal Diameter DN (mm) |

Dimension (mm) |

Weight (kg) |

Pipe Flange (for Reference) |

||||||||||

|

L |

D |

D1 |

D3 |

D2 |

Bolt Circle Diameter D1 |

Number of Bolts |

Bolt Metric Size |

Bolt Length L1 |

||||||

|

1.0 (Long Series) |

15 |

28 |

52 |

15 |

44 |

25 |

0.12 |

65 |

4 |

M12 |

75 |

|||

|

20 |

28 |

62 |

19 |

52 |

30 |

0.24 |

75 |

4 |

M12 |

90 |

||||

|

25 |

30 |

72 |

24 |

60 |

36 |

0.34 |

85 |

4 |

M12 |

90 |

||||

|

32 |

35 |

83 |

31 |

72 |

43 |

0.53 |

100 |

4 |

M16 |

100 |

||||

|

40 |

40 |

93 |

39 |

74 |

52 |

0.80 |

110 |

4 |

M16 |

105 |

||||

|

50 |

45 |

107 |

48 |

98 |

62 |

1.2 |

125 |

4 |

M16 |

125 |

||||

|

1.6 (Long Series) |

65 |

56 |

124 |

63 |

117 |

75 |

2.2 |

145 |

4 |

M16 |

130 |

|||

|

80 |

60 |

138 |

78 |

128 |

90 |

3.1 |

160 |

8 |

M16 |

135 |

||||

|

100 |

70 |

162 |

98 |

/ |

112 |

5.7 |

180 |

8 |

M16 |

150 |

||||

|

125 |

80 |

190 |

123 |

/ |

132 |

10 |

210 |

8 |

M16 |

180 |

||||

|

150 |

100 |

220 |

148 |

/ |

158 |

14 |

240 |

8 |

M20 |

180 |

||||

|

200 |

110 |

270 |

198 |

/ |

208 |

24 |

295 |

8 |

M20 |

240 |

||||

|

250 |

132 |

328 |

248 |

/ |

209 |

35 |

350 |

8 |

M20 |

260 |

||||

|

2.5 (Long Series) |

15 |

28 |

52 |

15 |

44 |

25 |

0.12 |

65 |

4 |

M12 |

80 |

|||

|

20 |

28 |

62 |

19 |

52 |

30 |

0.24 |

75 |

4 |

M12 |

90 |

||||

|

25 |

30 |

72 |

24 |

60 |

36 |

0.34 |

85 |

4 |

M12 |

90 |

||||

|

32 |

35 |

83 |

31 |

72 |

43 |

0.53 |

100 |

4 |

M16 |

110 |

||||

|

40 |

40 |

93 |

39 |

74 |

52 |

0.80 |

110 |

4 |

M16 |

115 |

||||

|

50 |

45 |

109 |

48 |

98 |

62 |

1.2 |

125 |

4 |

M16 |

125 |

||||

|

65 |

56 |

129 |

63 |

117 |

75 |

2.2 |

145 |

8 |

M16 |

135 |

||||

|

80 |

60 |

144 |

78 |

128 |

90 |

3.1 |

160 |

8 |

M16 |

145 |

||||

|

100 |

70 |

168 |

98 |

/ |

112 |

7.0 |

190 |

8 |

M20 |

160 |

||||

|

125 |

80 |

196 |

123 |

/ |

132 |

12 |

220 |

8 |

M24 |

205 |

||||

|

150 |

100 |

224 |

148 |

/ |

158 |

15 |

250 |

8 |

M24 |

225 |

||||

|

200 |

110 |

284 |

198 |

/ |

208 |

25 |

310 |

12 |

M24 |

260 |

||||

|

4.0 (Long Series) |

15 |

/ |

52 |

15 |

44 |

25 |

0.12 |

65 |

4 |

M12 |

80 |

|||

|

20 |

/ |

62 |

19 |

52 |

30 |

0.24 |

75 |

4 |

M12 |

90 |

||||

|

25 |

/ |

72 |

24 |

60 |

36 |

0.34 |

85 |

4 |

M12 |

90 |

||||

|

32 |

/ |

83 |

31 |

72 |

43 |

0.53 |

100 |

4 |

M16 |

110 |

||||

|

40 |

/ |

93 |

39 |

74 |

52 |

0.80 |

110 |

4 |

M16 |

125 |

||||

|

50 |

/ |

109 |

48 |

98 |

62 |

1.2 |

125 |

4 |

M16 |

125 |

||||

|

65 |

/ |

129 |

62 |

117 |

75 |

2.2 |

145 |

8 |

M16 |

135 |

||||

|

80 |

/ |

144 |

76 |

128 |

90 |

3.1 |

160 |

8 |

M16 |

145 |

||||

|

100 |

/ |

168 |

95 |

/ |

112 |

9 |

190 |

8 |

M20 |

160 |

||||

|

125 |

/ |

196 |

110 |

/ |

132 |

14 |

220 |

8 |

M24 |

205 |

||||