(API 624 Additional High Temperature Version)

Key Specifications / Features

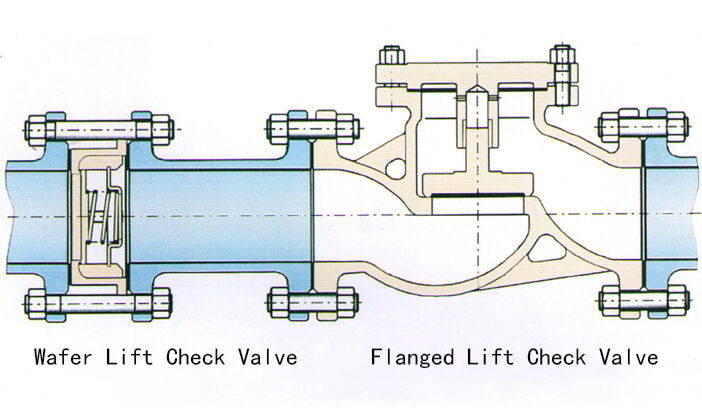

The Wafer Lift Check Valve Factory in China produces high-quality valves that meet API 594 standards. These valves are available in carbon steel (ASTM A216 WCB) and stainless steel (ASTM A351 CF3, CF8) materials, ensuring durability and corrosion resistance. They are designed in sizes ranging from DN15 to DN300 (1/2 to 12 inches) and can handle pressures from PN16 to PN100 and Class 150 to 400 LB. These valves feature wafer ends for easy installation and are suitable for a wide range of industrial applications.

- Model No.: MV-20250702-CSCV-02

- Hits: 12

- Categories: Cast Steel Check Valve

- Tags: Lift Check Valve, API 594 Check Valve, Wafer Check Valve

Detail Information

Product Name: Wafer Lift Check Valve

Type: Lift Check Valve

Design Standard: API 594

End Connection: Wafer

Face to Face Standard: ASME B16.10

Test & Inspection Standard: API 598

Material:

Carbon Steel: ASTM A216 WCB

Stainless Steel: ASTM A351 CF3, CF3M, CF8, CF8M

Size Range: DN15-DN300, 1/2-12 Inch

Pressure Range: PN16-PN100, Class 150-600 LB

Suitable Temperature: 0 to 200°C

Suitable Medium: Water, Oil, Steam, etc.

Direct Lift Check Valve with Wafer Type Connection

The wafer check valve is a general unidirectional flow valve. It is lightweight, compact, and easy to install between flanges. The valve body consists of two semicircular springs and a plate, with the spring fixed on the valve body. The spring deforms to close the valve plate, and the fluid pressure deforms the spring to open it quickly, thus protecting the pipeline from water hammer damage.

The wafer type check valve uses a wafer connection, with a compact structure. The stainless steel valve disc moves up and down along the centerline, with a short closing stroke and spring loading. It closes quickly, significantly reducing water hammer. The product features small size, lightweight, sensitive operation, reliable sealing, and easy installation, especially suitable for applications where installation space is limited. It can be used for water, steam, oil, nitric acid, acetic acid, and strong oxidizing substances.

Installation Notes

When installing the wafer check valve at the pump outlet, leave at least six times the diameter of the cast steel valve for space to ensure the valve plate is fully affected by the fluid.

For horizontally placed pipes, install the wafer check valve vertically within the operational radius of the valve plate to avoid adding pipe fittings and obstructions.

When installing the wafer check valve near elbows, ensure there is enough space. When placing pipes, pay attention to the flow direction of the wafer check valve to ensure it is consistent with the fluid flow direction. Install in vertically placed pipes.

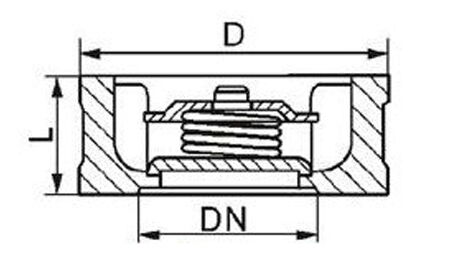

Main Connection Dimensions

|

Nominal Diameter |

L (mm) |

D 1.6 (mm) |

D 2.5 (mm) |

D 4 (mm) |

|

15 |

25 |

48 |

48 |

48 |

|

20 |

31.5 |

58 |

58 |

58 |

|

25 |

35.5 |

68 |

68 |

68 |

|

32 |

40 |

80 |

80 |

870 |

|

40 |

45 |

90 |

90 |

90 |

|

50 |

56 |

105 |

105 |

105 |

|

65 |

63 |

125 |

125 |

125 |

|

80 |

71 |

140 |

140 |

140 |

|

100 |

80 |

160 |

165 |

165 |

|

125 |

110 |

190 |

195 |

195 |

|

150 |

125 |

215 |

225 |

225 |

|

200 |

160 |

270 |

285 |

390 |

|

250 |

200 |

330 |

340 |

350 |

|

300 |

250 |

385 |

400 |

415 |