Key Specifications / Features

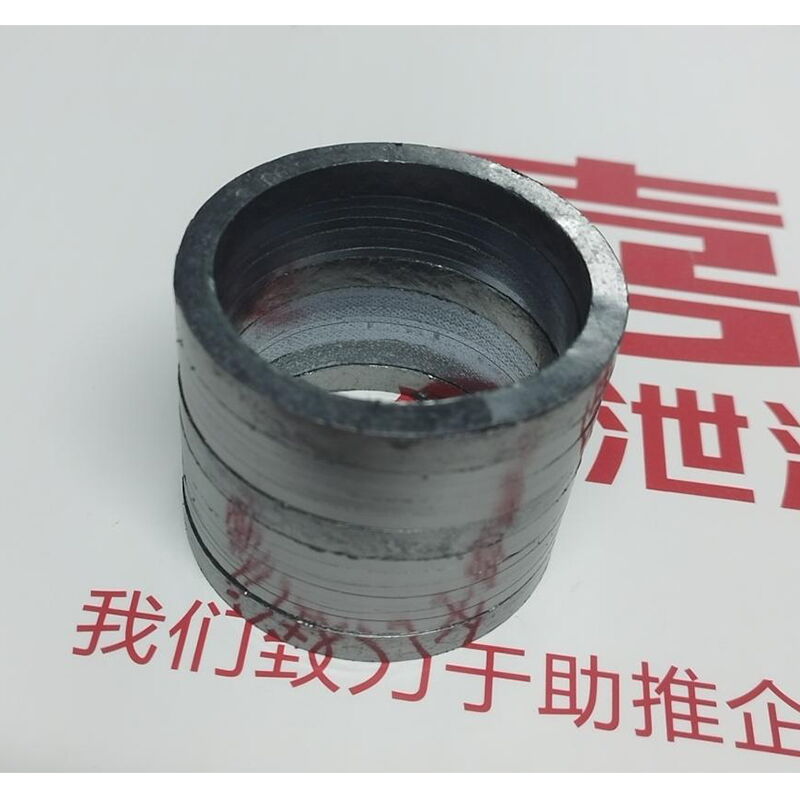

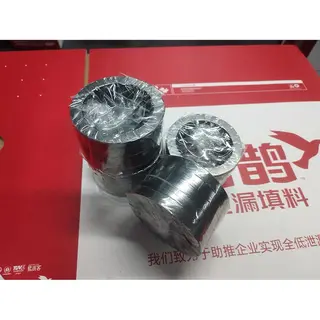

The Hard-Seal Ball Valve Packing Set Plant offers a high-quality packing solution for high-pressure hard-seal ball valves. This set features low emission characteristics and is designed with precision, boasting an outer diameter of 60mm and an inner diameter of 50mm. It includes 8 rings, each crafted with a minimum of 99% graphite purity, ensuring exceptional durability and reliability. This packing set is ideal for applications requiring stringent environmental and performance standards, providing a robust seal even under high-pressure conditions.

- Model No.: MV-20250625-GP-01

- Hits: 8

- Categories: Graphite Packing

- Tags: ISO 15848 Valve Packing, Graphite Valve Packing, Ball Valve Packing

Detail Information

Product Name: Low Emission Packing Set for High-Pressure Hard-Seal Ball Valve

Model: M641

Size: OD 60mm * ID 50mm * 8 Rings

Material Properties:

Graphite Purity: ≥99%

Metal Wire Content: 20% (Material options: Inconel 600 or 625)

Sulfur Content: ≤50PPM

Chlorine Content: ≤20PPM

Features:

This engineered low-emission/leakage valve packing set utilizes a woven metal wire-reinforced expanded graphite ring with a highly adaptable core. The permanent elastic components of the sealing kit ensure minimal leakage rates and reduced friction throughout the valve's lifecycle. Our sealing kit is specifically designed for low-emission leakage valve applications.

Advantages:

High-temperature resistance and chemical resistance

Full compliance with the latest fugitive emission regulations

Excellent sealing performance and permanent elasticity

Good anti-extrusion performance under high pressure

Optimized ring configuration requires lower compression force

Operating Parameters

Speed: 2 m/s

Temperature Range: -200°C to +400°C (for most media), -200°C to +550°C (for steam)

pH Value: 0 to 14

Pressure: 25 MPa

Media: Suitable for most chemical substances (solvents, hydrocarbons, acids, alkalis, steam, alcohol, oil)

Certifications/Licenses: TA-Luft, ISO 15848, API 589 (Fire Safe)

Except for strong oxidizing acids, such as sulfuric acid and nitric acid.

Low Emission Standards

1. ISO 15848

ISO 15848 standardizes the measurement, testing, and evaluation procedures for industrial valve fugitive emissions. This standard is divided into two parts. ISO 15848-1 defines the test procedures for valve type testing, and ISO 15848-2 specifies the requirements for the manufacturing of valve products.

2. TA- LUFT (VDI 2440)

The German fugitive emission control law TA-LUFT VDI2440 defines the leakage rate, testing, and testing methods.

3. VDI2200, VDI2440 and TA- LUFT Flange Connection

According to TA-LUFT and VDI 2440, the flange connection must meet the test pressure of 1 bar under the condition that the leakage rate is less than 10−4 mbar × l/(s × m). VDI 2200 specifies the selection, calculation, design, installation, and testing process of the flange connection. It also allows reference to VDI 2440 for the leakage rate. VDI 2200 also stipulates the burst pressure test to avoid the risk of flange breakage and sudden leakage.

4. CLEAN AIR ACT

The Clean Air Act stipulates that the maximum allowable leakage rate for valves, pumps, and agitators in the United States must comply with the EPA Method21 (blower method) for leakage testing, and the testing method must be consistent.

5. API 622

API 622 is the second edition of the international performance test for disk root materials, which includes temperature, pressure, thermal cycles, and mechanical cycles. API 622 specifies 1510 mechanical cycles and 5 thermal cycles, from room temperature to 260°C (500°F), pressure from 0 to 600 psi (0-41bar), for high-temperature testing. Under carbon equivalent testing, the allowable leakage rate is 100 ppm.

6. API 624

The first edition of the API 624 standard for the type test of the fugitive emission of the valve with a graphite seal includes the up and down motion and rotation of the valve, with a maximum diameter of 24 inches. The test requires the temperature to rise to 260°C (500°F) and perform 310 mechanical cycles and 3 thermal cycles, with the maximum allowable leakage rate being 100 ppm. The valve to be tested must first be tested according to API 622, and the temperature range is from -29°C to 538°C (-20°F to 1000°F).

ISO 15848 Sealing Grades

|

Grade |

Leakage Rate |

Remarks |

|

A (Gas only) |

≤ 10−6 mg / (s × m) |

Generally, valves with bellows seals or double seals can reach this grade |

|

B |

≤ 10−4 mg / (s × m) |

Generally, PTFE lined valves with good sealing (such as diaphragm valves) can reach this grade |

|

C |

≤ 10−2 mg / (s × m) |

Generally, valves with soft sealing materials can reach this grade |

VDI2440 Specifies the Maximum Leakage Rate of Valves with Harmful and Combustible Substances

|

Temperature |

Leakage Rate |

|

< 250°C |

≤ 10−4 mbar × l / (s × m) |

|

≥ 250°C |

≤ 10−2 mbar × l / (s × m) |