Key Specifications / Features

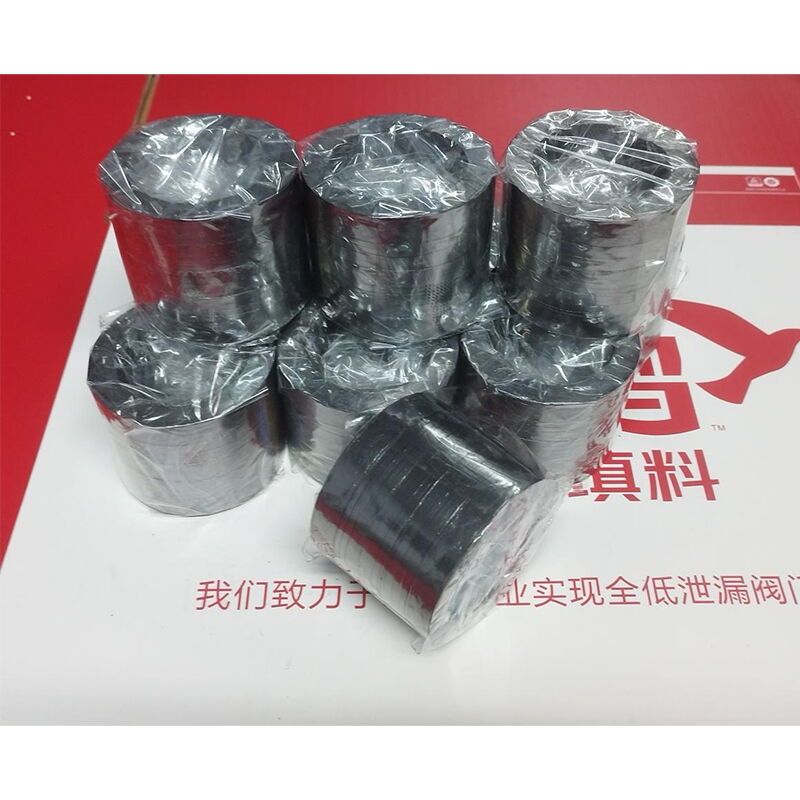

The Low Emission Gate Valve Packing Set Factory produces high-performance packing sets tailored for gate valves. Each set features an inner diameter of 48mm and an outer diameter of 68mm, comprising 5 rings made from expanded graphite reinforced with Inconel wire. This combination ensures excellent high-temperature resistance and durability, making it ideal for applications where thermal stability and low emissions are critical.

- Model No.: MV-20250625-GP-02

- Hits: 21

- Categories: Graphite Packing

- Tags: ISO 15848 Valve Packing, Gate Valve Packing, Low-Emission Packing Set

Detail Information

Product Name: Low Emission Packing Set for Gate Valves

Size: ID 48mm * OD 68mm * 5 Rings

Model: M600

Material Properties:

Graphite Purity: ≥99%

Metal Wire Content: 20% (Material options: Inconel 600 or 625)

Sulfur Content: ≤50PPM

Chlorine Content: ≤20PPM

Features:

This engineered low-emission/leakage valve packing set utilizes a woven metal wire-reinforced expanded graphite ring with a highly adaptable core. The permanent elastic components of the sealing kit ensure minimal leakage rates and reduced friction throughout the valve's lifecycle. Our sealing kit is specifically designed for low-emission leakage valve applications.

Advantages:

High-temperature resistance and chemical resistance

Full compliance with the latest fugitive emission regulations

Excellent sealing performance and permanent elasticity

Good anti-extrusion performance under high pressure

Optimized ring configuration requires lower compression force

Operating Parameters

Speed: 2 m/s

Temperature Range: -200°C to +400°C (for most media), -200°C to +550°C (for steam)

pH Value: 0 to 14

Pressure: 25 MPa

Media: Suitable for most chemical substances (solvents, hydrocarbons, acids, alkalis, steam, alcohol, oil)

Certifications/Licenses: TA-Luft, ISO 15848, API 589 (Fire Safe)

Except for strong oxidizing acids, such as sulfuric acid and nitric acid.

Standards and Regulations on Fugitive Emissions

Fugitive emissions typically refer to the unintentional release of gases or vapors from industrial facilities, which can have significant impacts on health, safety, and the environment. Surveys show that these emissions mostly come from valves and flanges, with valve issues being the most prominent. Fortunately, a comprehensive approach can significantly reduce such emissions. For example, between 1990 and 2011, the emissions of non-methane volatile organic compounds (NMVOC) in Europe were reduced by 57%. This progress was driven by legislative frameworks, such as the European Industrial Emission Directive (IED 2010/75/EU) and the European Integrated Pollution Prevention and Control (IPPC). The concept of Best Available Techniques (BAT) and the BREF reference documents support end-users' efforts to comply with stricter emission standards, which have been incorporated into national standards like the German Air Quality Standards.

Burgmann Packings actively promotes this process by developing and manufacturing fugitive emission control (FEC) products that meet and exceed the strictest leakage regulations. In addition to internal testing, these products have also been certified by independent testing agencies.

Evidence and Impact

Evidence from around the world shows that another key factor in reducing overall on-site leakage is the implementation of Leak Detection and Repair (LDAR) programs. These programs intuitively identify the most severe leakage points and focus on maintenance and repair to achieve short-term, high-impact results. As the market leader in LDAR fugitive emission management projects, The Sniffers has completed over 6,000 LDAR projects globally in the past 25 years. Data from a European refinery's emission reduction project show that by implementing a coordinated and effective plan, annual emissions can be reduced by 75%.

Compliance is just one major advantage for plant operators. Improvements in various health, safety, and environmental (HSE) factors have produced measurable results. Moreover, life cycle cost analysis indicates that reducing the leakage of expensive process media can also increase profits.