(API 624 Additional High Temperature Version)

Key Specifications / Features

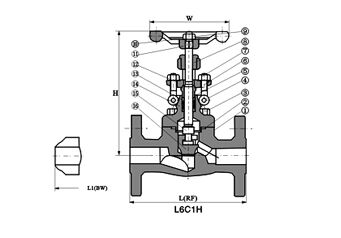

The Custom Forged Globe Valve Factory in China specializes in producing high-quality forged globe valves made from carbon steel, stainless steel, and alloy steel. These valves are designed for on-off control and are available in sizes ranging from DN15 to DN50 (1/2 to 2 inches) and pressure ratings from PN16 to PN320. They feature flanged ends and are suitable for a variety of industrial applications. The valves are manufactured to meet international standards, ensuring reliability and performance.

- Model No.: MV-20250705-FSGLV-01

- Hits: 16

- Categories: Forged Steel Globe Valve

- Tags: Stainless Steel Globe Valve, Carbon Steel Globe Valve, Forged Steel Globe Valve

Detail Information

Product Name: Custom Forged Globe Valve

Main Function: On-off Control

Standard: MFG, Custom

Material: Forged Steel, Carbon Steel, Stainless Steel, Alloy Steel

Nominal Diameter: DN15-DN50, 1/2-2 Inch

Operating Pressure: 1.6MPA-32MPA, PN16-PN320

Connection Method: Flanged

Operation: Manual

Applicable Medium: Water, oil, steam

Forged steel flanged globe valves are a type of automatic valve. Forged steel flanged globe valves are used in piping systems, and their main functions are to prevent medium backflow, prevent pumps and their driving motors from reversing, and to release the medium inside the container. Globe valve products can also be used in auxiliary systems where the pressure may rise above the main system pressure to provide replenishment in the pipeline.

|

No. |

Part Name |

CS to ASTM Type A105 |

AS to ASTM Type F22 |

SS to ASTM Type F304(L) |

SS to ASTM Type F316(L) |

|

1 |

Valve Body |

A105 |

A182 F22 |

A182 F304(L) |

A182 F316(L) |

|

2 |

Gasket |

Corrugated SS+graphite |

SS+PTFE |

||

|

3 |

Bolt |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

|

4 |

Pin |

A276 420 |

A276 304 |

||

|

5 |

Packing Gland |

A276 410 |

A182 F304(L) |

A182 F316(L) |

|

|

6 |

Eyebolt |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

|

7 |

Nut |

A194 2H |

A194 4 |

A194 8 |

A194 8M |

|

8 |

Valve Stem Nut |

A276 410 |

|||

|

9 |

Nut |

A194 2H |

A194 4 |

A194 8 |

A194 8M |

|

10 |

Nameplate |

SS |

|||

|

11 |

Handwheel |

A197 |

|||

|

12 |

Packing Gland Plate |

A216 WCB |

A351 CF8 |

||

|

13 |

Packing |

Flexible Graphite |

PTFE |

||

|

14 |

Valve Cover |

A105 |

A276 304 |

A182 F304(L) |

A182 F316(L) |

|

15 |

Valve Stem |

A182 F6 |

A182 F304 |

A182 F304(L) |

A182 F316(L) |

|

16 |

Disc |

A276 420 |

A276 304 |

A276 304(L) |

A276 316(L) |

|

Applicable Medium |

Water, steam, oil, etc. |

Water, steam, oil, etc. |

Nitric acid, acetic acid, etc. |

||

|

Applicable Temperature |

-29°C to 425°C |

-29°C to 550°C |

-29°C to 180°C |

||

Note: Other materials required by customers can also be used. The sealing surface material is determined by the customer-specified internal part number.

CS = Carbon Steel; AS = Alloy Steel; SS = Stainless Steel

|

NPS |

1/2 Inch |

3/4 Inch |

1 Inch |

1-1/4 Inch |

1-1/2 Inch |

2 Inch |

|

|

L (RF) |

Class 150 LB |

108 |

117 |

127 |

140 |

165 |

203 |

|

Class 300 LB |

152 |

178 |

203 |

216 |

229 |

267 |

|

|

Class 600 LB |

165 |

190 |

216 |

229 |

241 |

292 |

|

|

H (Open) |

Class 150-300 LB |

166 |

171 |

207 |

240 |

258 |

330 |

|

Class 600 LB |

171 |

207 |

240 |

258 |

330 |

380 |

|

|

W |

100 |

100 |

125 |

160 |

160 |

180 |

|

|

Weight |

Class 150 LB |

4.5 |

6.9 |

9.8 |

13.5 |

19.5 |

28.0 |

|

2.3 |

3.6 |

7.8 |

8.2 |

12.0 |

15.0 |

||

|

Class 300 LB |

4.8 |

7.7 |

11.0 |

16.8 |

21.2 |

32.6 |

|

|

2.8 |

4.0 |

8.5 |

9.2 |

12.6 |

16.8 |

||

|

Class 600 LB |

5.6 |

7.8 |

12.5 |

17.0 |

23.5 |

38.8 |

|

|

3.4 |

4.7 |

9.2 |

10.5 |

13.3 |

18.9 |

||

Similar Products

Custom Forged Globe Valve, Carbon/Stainless Steel, 1/2-20 IN